Patents

Literature

132 results about "CHROMIUM COMPLEX" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium compositions and methods for using the same for inhibiting drug-induced insulin resistance

InactiveUS20050214384A1Avoid seizuresAvoid developmentBiocideHeavy metal active ingredientsDietary ChromiumInsulin resistance

A method for inhibiting drug-induced insulin resistance is provided which includes administering a dietary chromium complex to an individual receiving a contemporaneous dose of a drug that induces insulin resistance, wherein the amount of chromium complex administered is an amount effective to inhibit the development of insulin resistance. Advantageously, the amount of chromium complex administered per day is between about 300 and 1,000 micrograms per day. Compositions including a drug which induces insulin resistance in combination with a chromium complex are similarly described.

Owner:N21 ACQUISITION HLDG

Catalyst composition and olefin polymerization using same

InactiveUS6911506B2High purityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionButeneOligomer

Novel metal complexes, particularly chromium complexes, which contain at least one tridentate ligand are disclosed and prepared. Olefins, particularly ethylene, can be reacted to form butene and / or other homo- or co-oligomers and / or polymers with high α-olefin concentrations by contacting a metal catalyst which contains a transition metal, particularly chromium, complexes having per metal atom at least one tridentate ligand with N, O, or N and O coordinating sites.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Phenolic antioxidant-chromium complexes for treatment or prevention of type 2 diabetes or glucose intolerance

InactiveUS20050085454A1Reducing hyperglycemiaStabilize blood sugar levelsBiocideHeavy metal active ingredientsMedicinePhenolic antioxidant

A composition for the treatment, prevention or management of a condition in primates, especially humans comprising a phenolic antioxidant-chromium complex.

Owner:INDIAN HERBS RES & SUPPLY +1

Catalyst composition and olefin polymerization using same

InactiveUS7056997B2High purityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsButeneOligomer

Novel metal complexes, particularly chromium complexes, which contain at least one tridentate ligand are disclosed and prepared. Olefins, particularly ethylene, can be reacted to form butene and / or other homo- or co-oligomers and / or polymers with high α-olefin concentrations by contacting a metal catalyst which contains a transition metal, particularly chromium, complexes having per metal atom at least one tridentate ligand with N, O, or N and O coordinating sites.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Methods and compositions for the sustained release of chromium

ActiveUS8062677B2Reducing pre-prandialReducing hyperglycemiaBiocideHeavy metal active ingredientsMedicineCHROMIUM COMPLEX

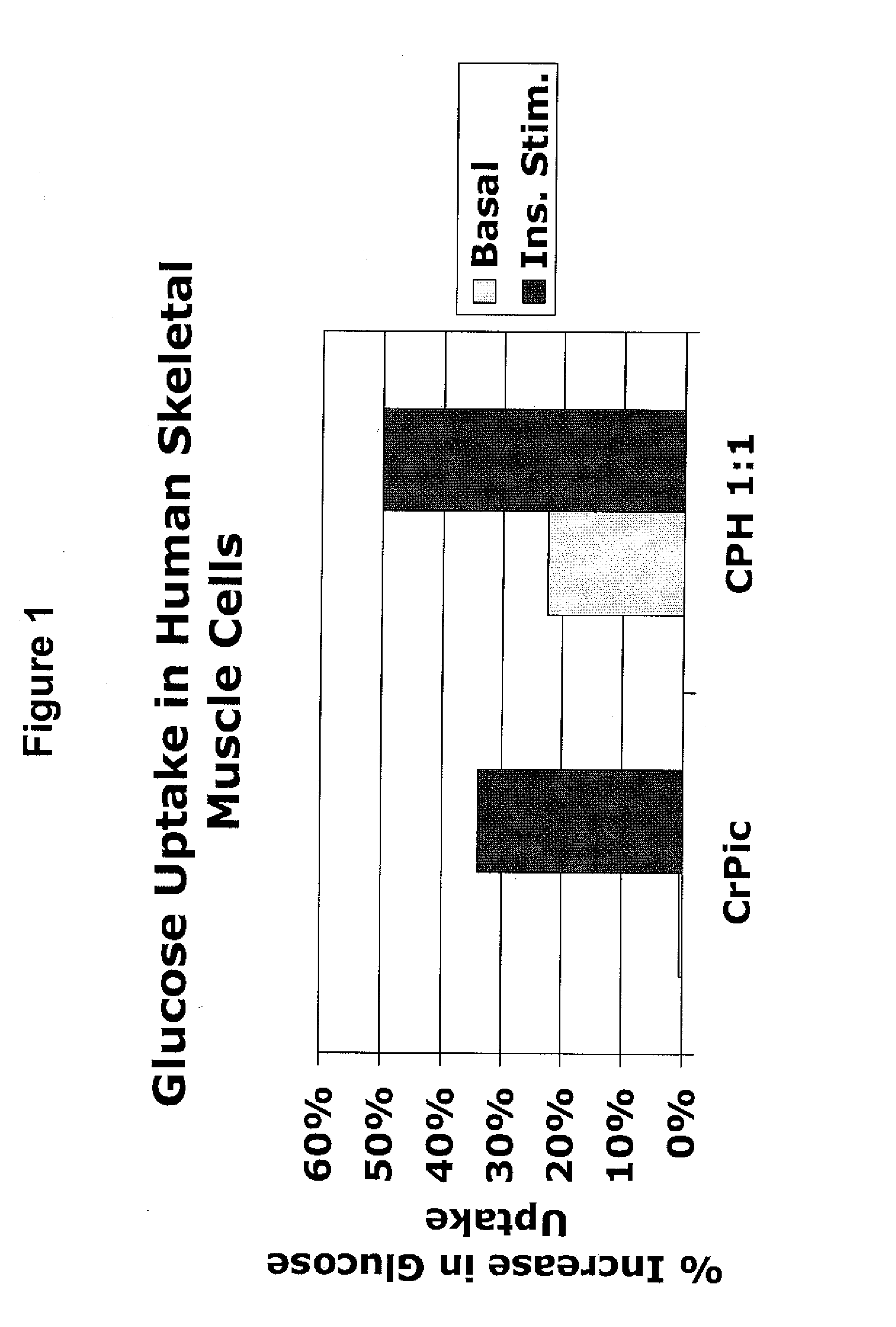

Provided herein are compositions for the administration of chromium that include at least two components: a hydrophilic chromium complex and a lipophilic chromium complex, and methods of using the same. Also provided are compositions for the administration of chromium that include a first “fast-acting” chromium complex and a second “slow-acting” chromium complex, wherein the first chromium complex is absorbed more quickly than the slow-acting chromium complex, and methods of using the same. Also provided herein are methods for treating, preventing, and improving conditions associated with cardiometabolic syndrome, by identifying a subject in need of treatment, prevention, or improvement of a condition associated with cardiometabolic syndrome, and providing a therapeutically effective amount of a composition comprising a fast-acting chromium complex and a slow-acting chromium complex, to the individual.

Owner:NUTRITION 21 INC

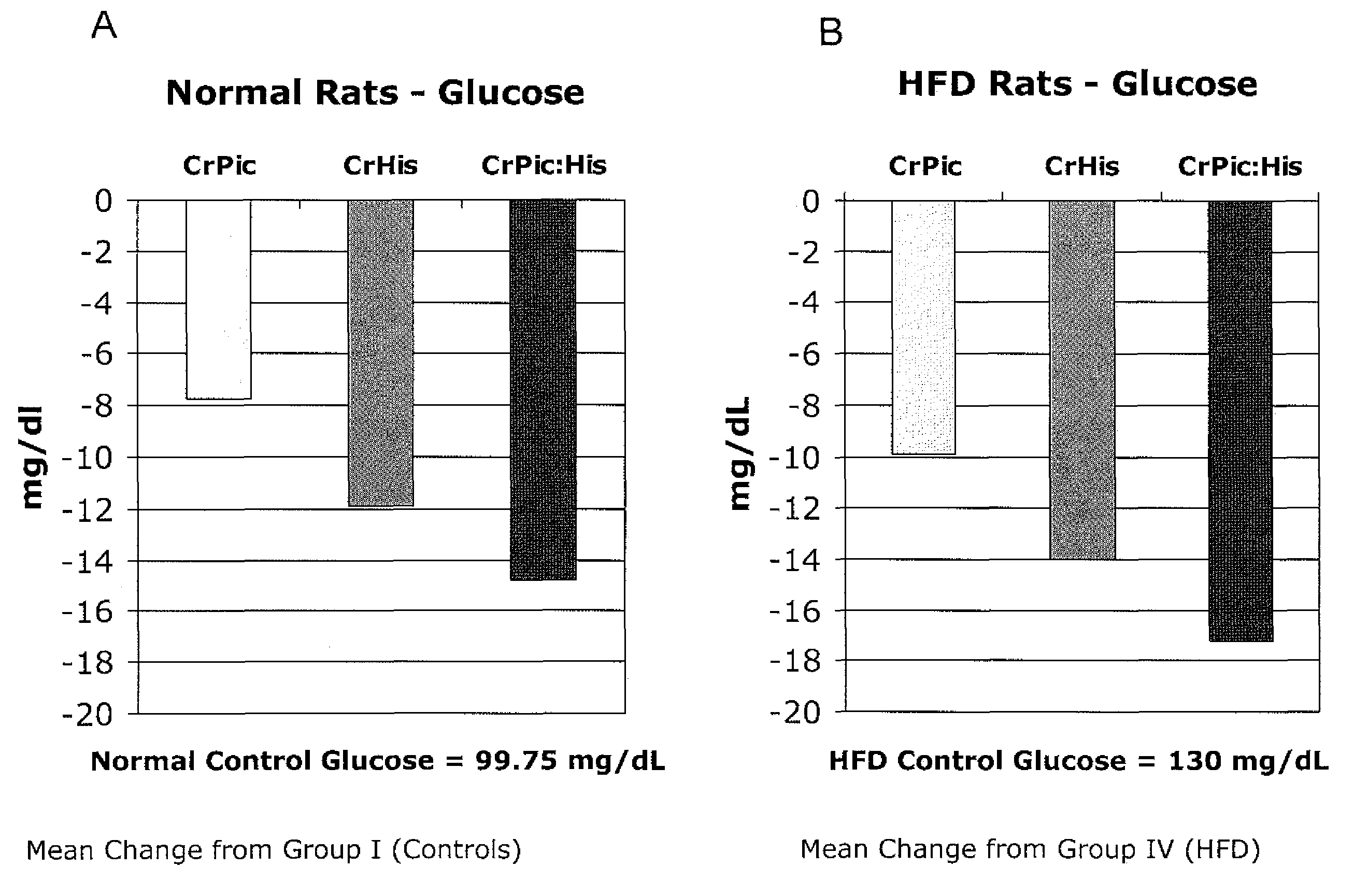

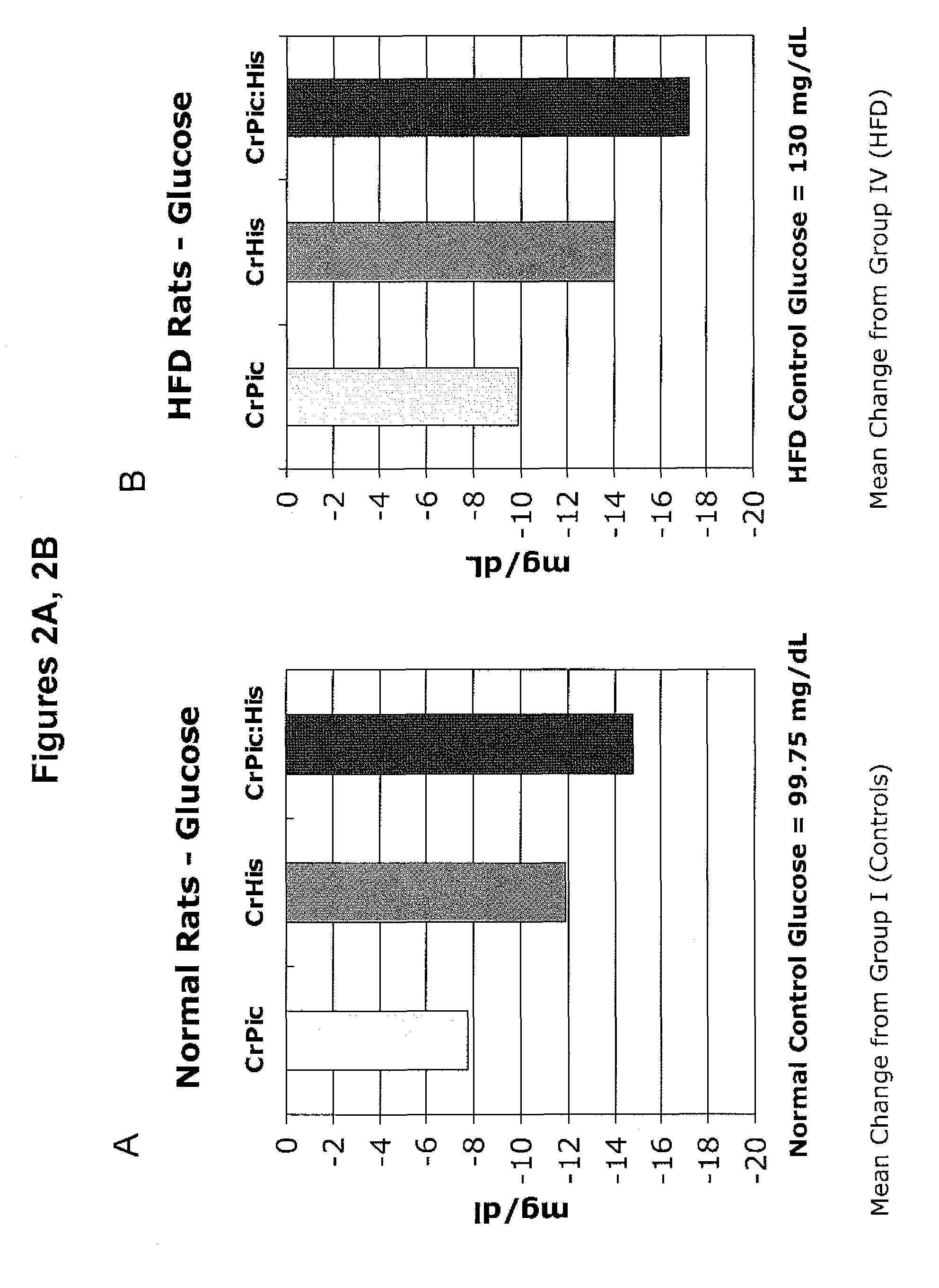

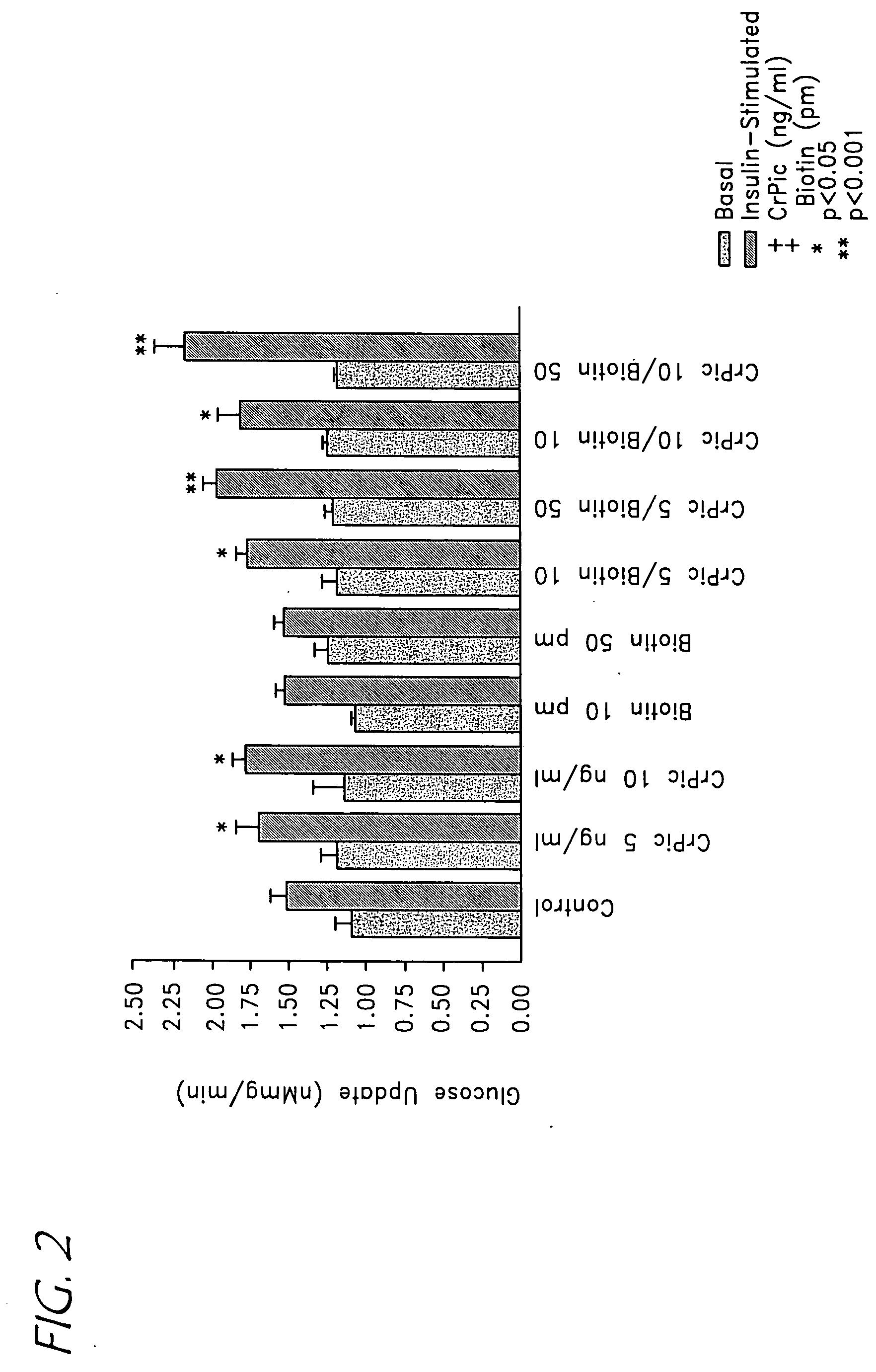

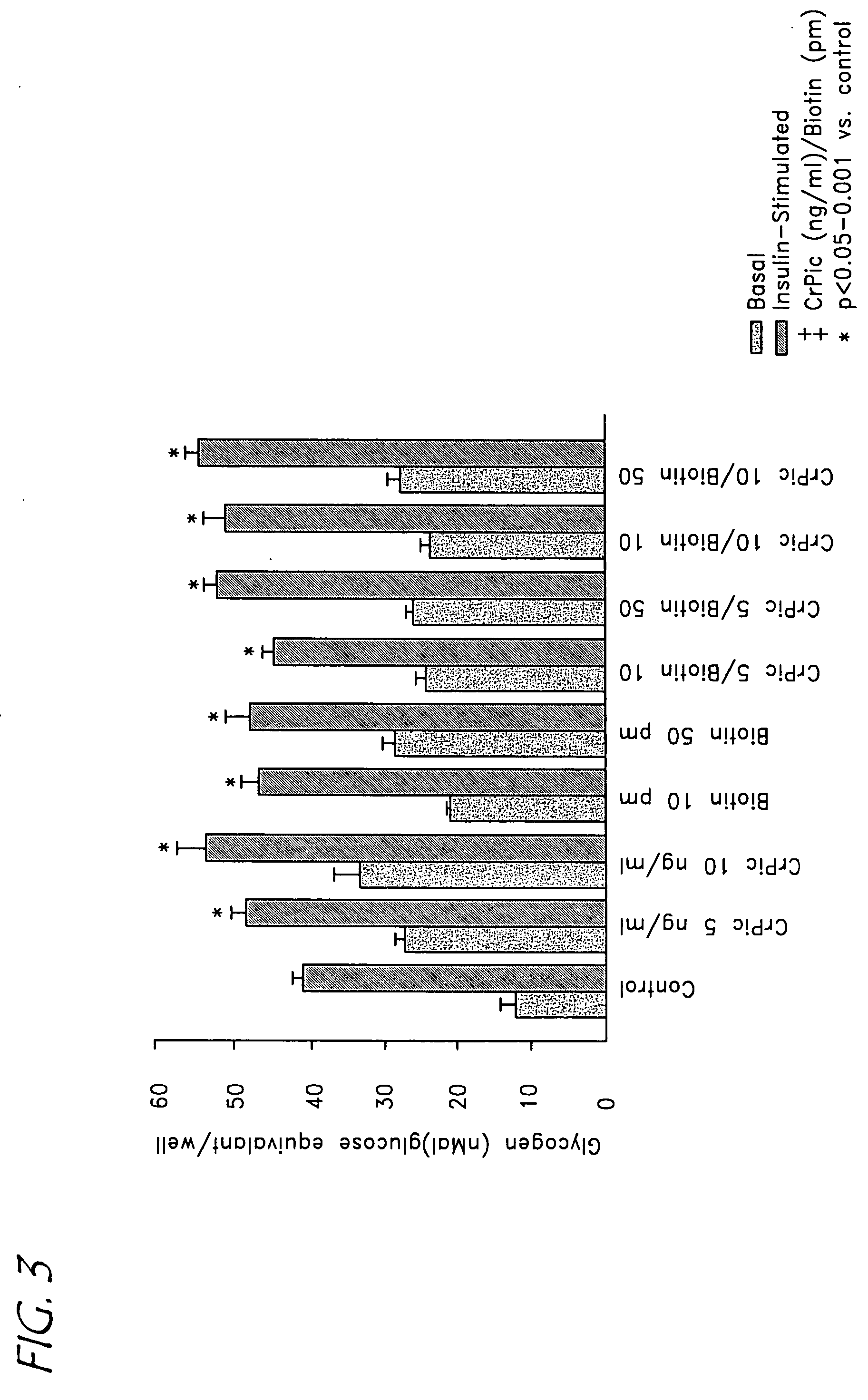

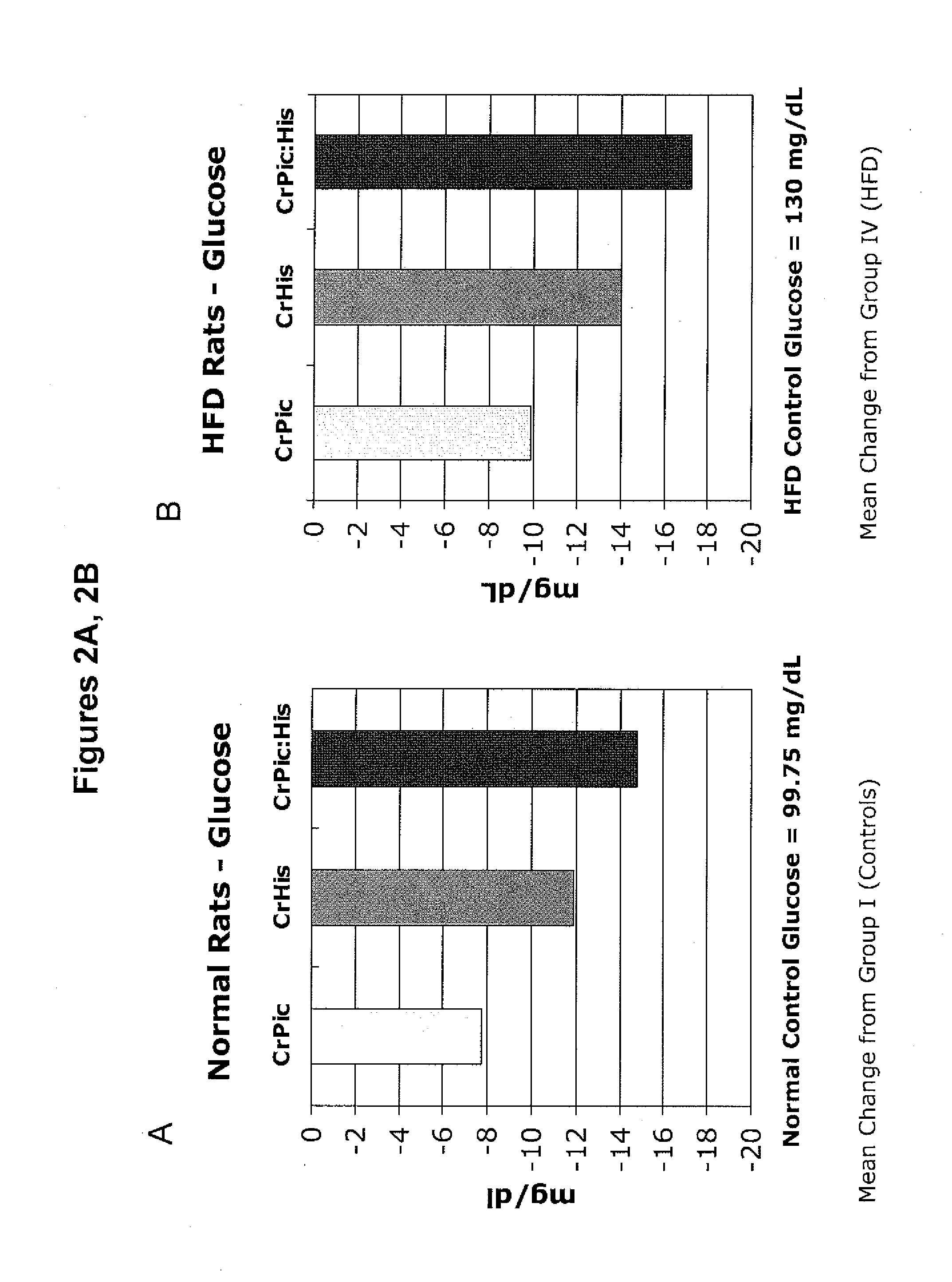

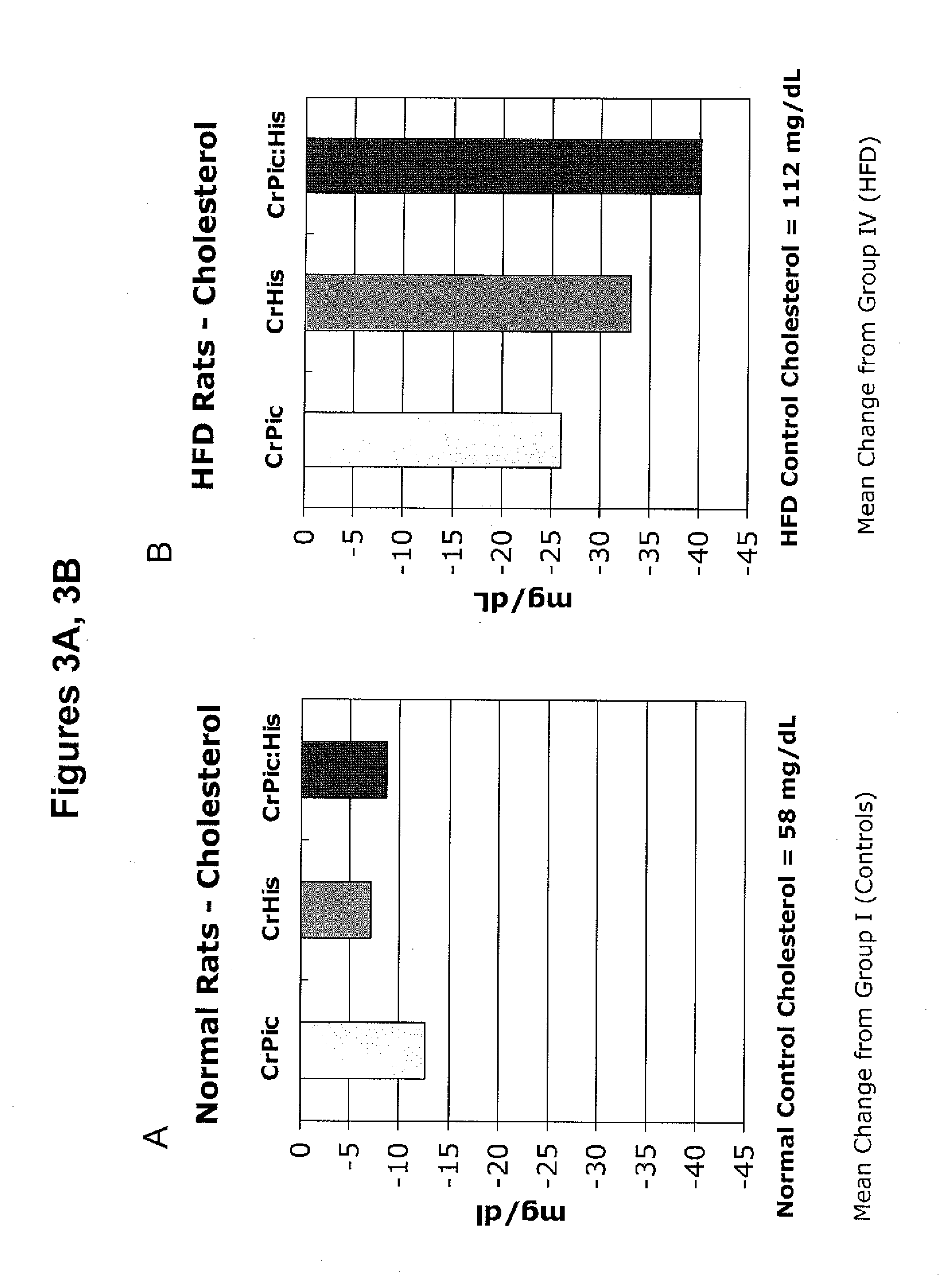

Chromium/biotin treatment of dyslipidemia and diet-induced post prandial hyperglycemia

InactiveUS20050214385A1Reducing post prandial hyperglycemiaReduce post-prandial hyperglycemiaHeavy metal active ingredientsBiocideAcute hyperglycaemiaDyslipidemia

A method for treating dyslipidemia and / or post prandial hyperglycemia by administering a combination of a chromium complex and biotin to an individual in need thereof is disclosed. The two compounds are administered orally or parenterally in daily dosages which provide between 25 μg and 1,000 μg of chromium and between 25 μg and 20 mg biotin. A method for reducing the glycemic index of food is similarly provided.

Owner:JDS THERAPEUTICS

Sulfate trivalent-chromium chromeplate electroplating solution and application method thereof

The invention provides a sulfate trivalent-chromium chromeplate electroplating solution and an application method thereof. Amine compounds and organic compounds containing nitrogen, sulfur, acetylenicalcohol and the like, which are used as brighteners, are added into a basic electroplating solution containing chromium sulfate and conducting salt; hydroxylamine hydrochloride or ascorbic acid is added for stabilizing trivalent chromium in the electroplating solution, substances such as polyethers and polyalcohols are added as surfactants, and low carbon chain material complexing agents such asoxalic acid, propionic acid, glycine and succinic acid are added for complexing trivalent chromium ions, so that the cathodic reduction of the trivalent chromium complex ions is greatly promoted, andthe tolerance of the electroplating solution to impurities and the stability of the electroplating solution are further improved; the brighteners and the surfactants also can promote the cathodic reduction of the trivalent chromium ions, and appropriate processing parameters are cooperatively set, so that the reaction effects of all components can be greatly improved; the sulfate trivalent-chromium chromeplate electroplating solution can enable plating to have excellent appearance, morphology, structure, binding force and corrosion resistance, and enables the plating not to have surface defects such as pinholes and stripes.

Owner:MINNAN NORMAL UNIV +1

Methods and compositions for improved chromium complexes

Complex metal-containing matrices, and especially chromium-containing matrices are produced from a water soluble preparation that is derived from an item suitable for animal (and most typically human) consumption. In particularly contemplated aspects, the water soluble preparation is an extract or filtrate of disintegrated brewer's yeast, and the so prepared complex mixture is combined with a chromium-3+ ions.

Owner:MILJKOVIC DUSAN +2

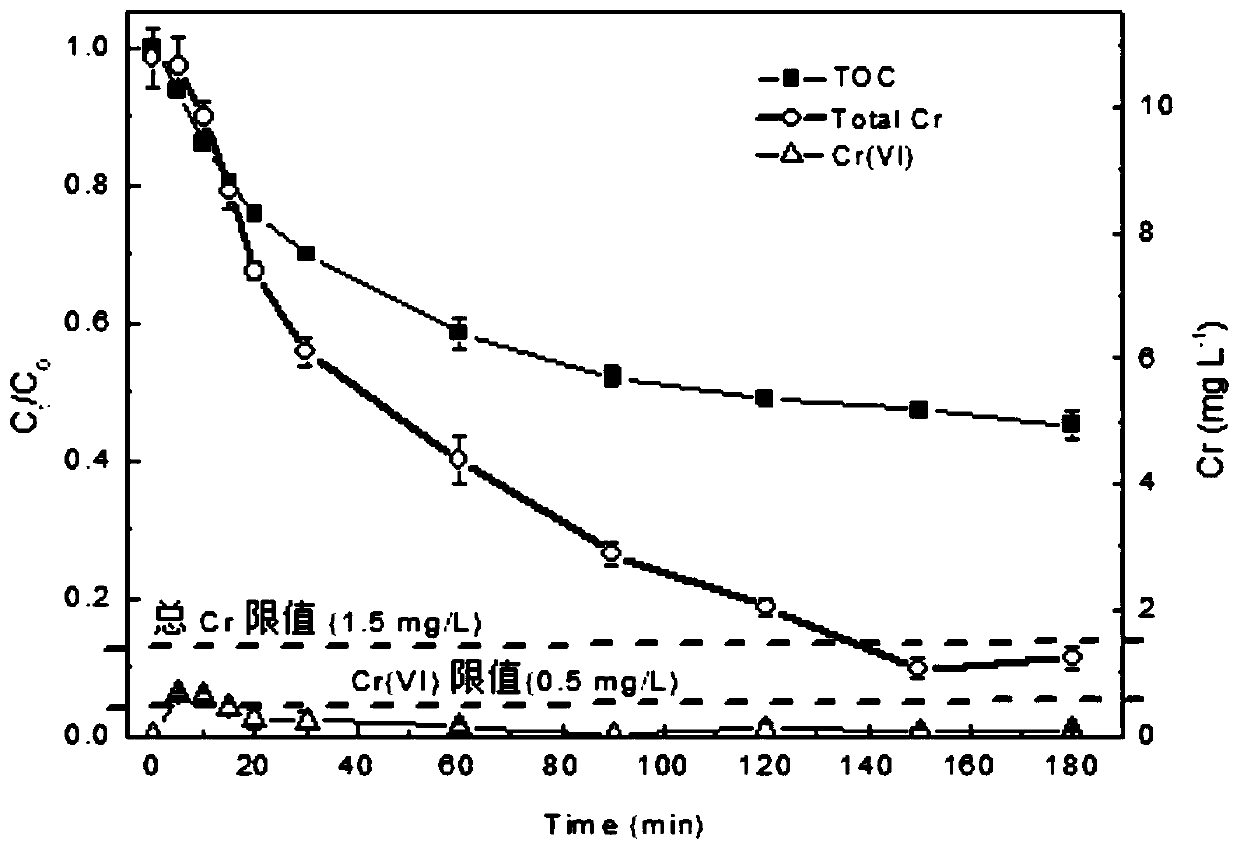

A method for treating trivalent chromium complex wastewater and synchronously recovering chromium with reducing compound agent combined with ultraviolet light

ActiveCN108439533BHas a reducing effectLow residual concentrationWater/sewage treatment by irradiationWater contaminantsPhoto irradiationUltraviolet lights

The invention discloses a method for treating trivalent chromium complexing wastewater and synchronously recycling chromium by combination of a reducing composite chemical agent and ultraviolet light,and belongs to the field of waste water treatment. A method for treating a copper complex and synchronously removing copper by combination of a reducing composite chemical agent / UV comprises the following steps: A, chemical feeding: feeding the reducing composite chemical agent in trivalent chromium complexing wastewater and stirring, and regulating pH of the wastewater to be 4-10; B, ultravioletillumination: carrying out ultraviolet light illumination treatment on the waste water which is stirred uniformly, and separating out chromium in a precipitate mode; and C, chromium recycling: recycling chromium by a solid-liquid separating method. By the method, trivalent-chromium-containing complexing wastewater such as leather making, electroplating and dyestuff can be safely and effectively treated, and the chromium can be recycled.

Owner:温州大学苍南研究院

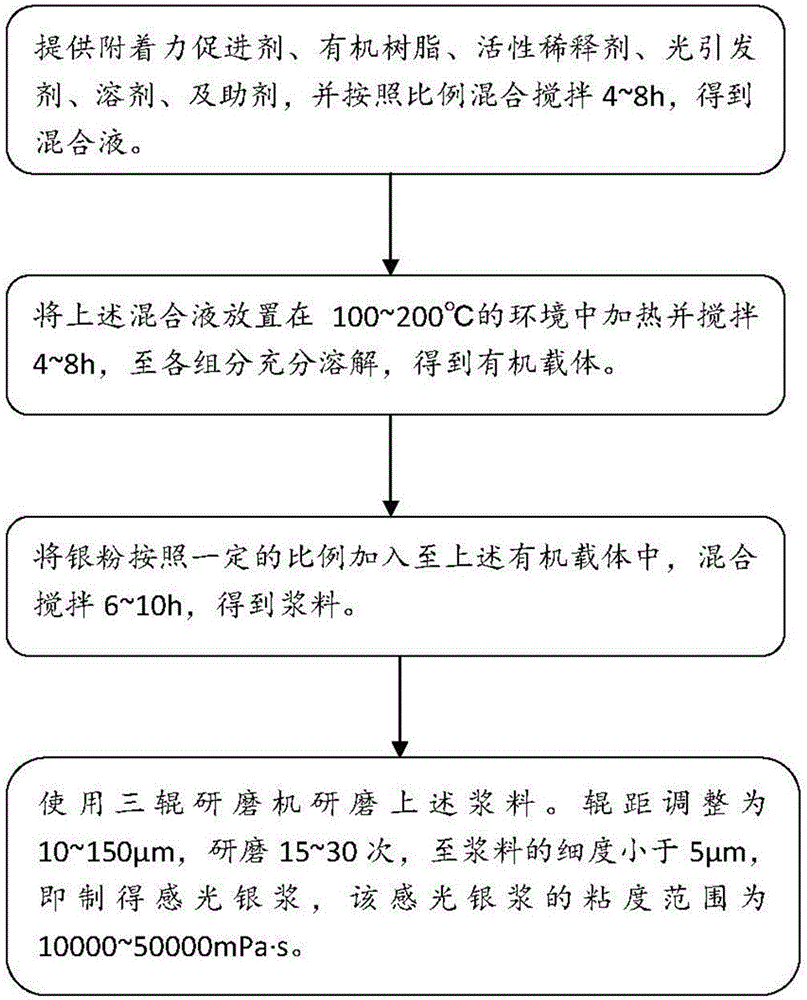

Photosensitive silver paste and touch screen and electronic apparatus employing photosensitive silver paste

InactiveCN104966544AImprove adhesionImprove yieldNon-conductive material with dispersed conductive materialSolventElectron

Provided is photosensitive silver paste, comprising an organic carrier, and aluminum powder dispersed in the organic carrier. The organic carrier comprises organic resin, an active diluent, a photoinitiator and a solvent, and also comprising an adhesion promoter which comprises one or more than one selected from the group of a phosphorus containing compound, a chromium complex coupling agent, a titanate coupling agent, and an aluminate coupling agent. The photosensitive silver paste is provided with the adhesion promoter, thereby effectively improving the adhesive force of silver paste on a substrate surface, accordingly reducing a reject ratio in the preparation of a conducting circuit by common photosensitive silver paste, increasing a yield rate, and reducing cost. In addition, the invention provides the touch screen prepared by the photosensitive silver paste, and the electronic apparatus employing the touch screen.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +5

Methods and compositions for the sustained release of chromium

InactiveUS20120128794A1Reducing pre-prandialReducing hyperglycemiaHeavy metal active ingredientsBiocideMedicineCHROMIUM COMPLEX

Provided herein are compositions for the administration of chromium that include at least two components: a hydrophilic chromium complex and a lipophilic chromium complex, and methods of using the same. Also provided are compositions for the administration of chromium that include a first “fast-acting” chromium complex and a second “slow-acting” chromium complex, wherein the first chromium complex is absorbed more quickly than the slow-acting chromium complex, and methods of using the same. Also provided herein are methods for treating, preventing, and improving conditions associated with cardiometabolic syndrome, by identifying a subject in need of treatment, prevention, or improvement of a condition associated with cardiometabolic syndrome, and providing a therapeutically effective amount of a composition comprising a fast-acting chromium complex and a slow-acting chromium complex, to the individual.

Owner:NUTRITION 21 INC

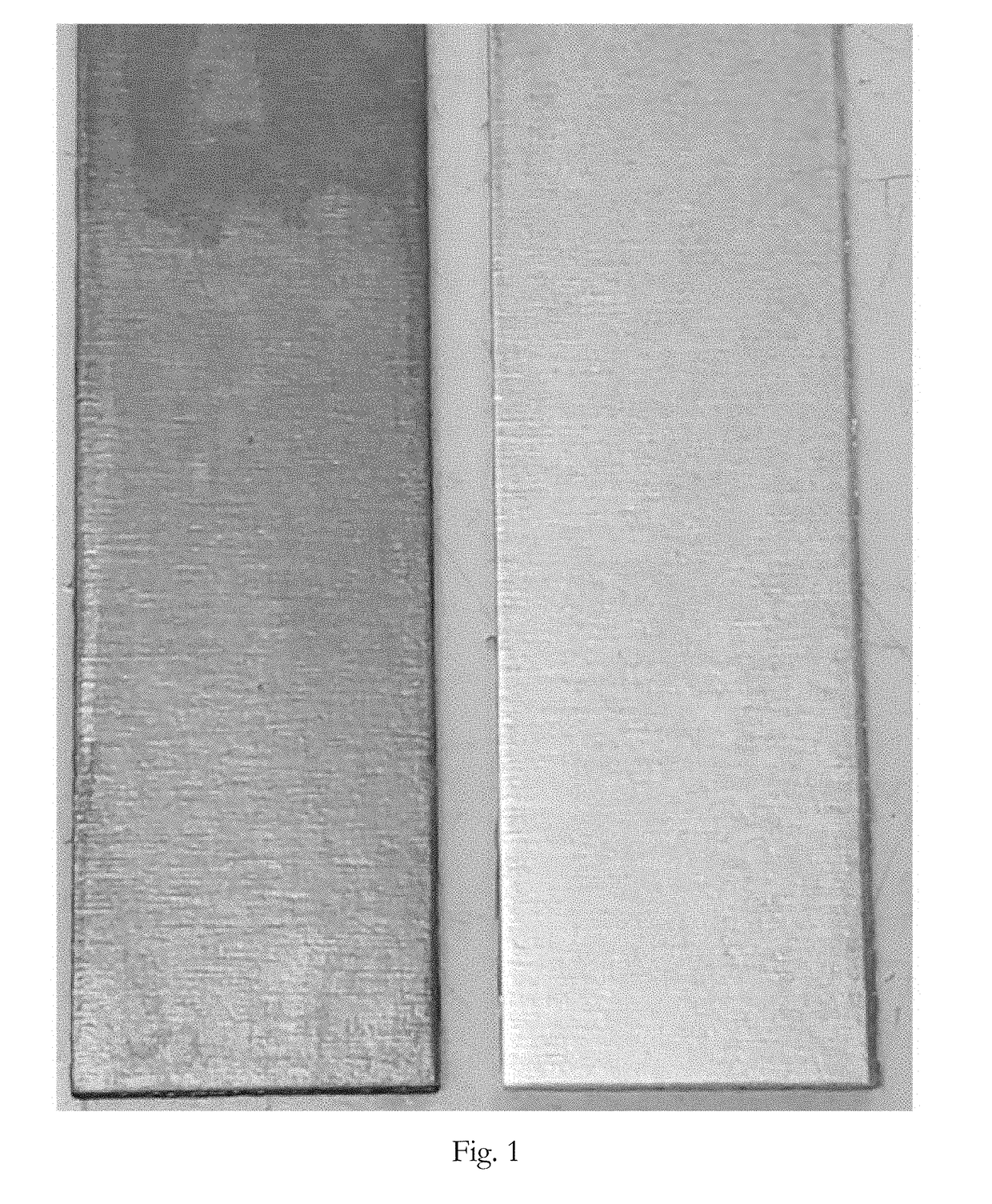

Trivalent chrome complex for hot dip aluminum-zinc plate and preparation method of trivalent chrome complex

ActiveCN105088208ANo harmOvercome instability and other issuesMetallic material coating processesZincAcid substances

The invention relates to a preparation method of a trivalent chrome complex, in particular to a passivation processing solution for an environment-friendly hot dip aluminum-zinc plate and a passivation processing solution with excellent corrosion resistance. The trivalent chrome complex for the hot dip aluminum-zinc plate is prepared from water, hexavalent chromium, reducing agents and acidic materials according to the molar ratios of 100:0.2-1.5:0.1-4.5:0.2-7.5. The trivalent chrome complex for the hot dip aluminum-zinc plate has excellent corrosion resistance. Corrosion resistance of a solidified coating reaches the passivation level of hexavalent chromium, the requirement for environmental friendliness can be met, harmful elements like hexavalent chromium are not contained, and the trivalent chrome complex does not harm the environment or human bodies.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

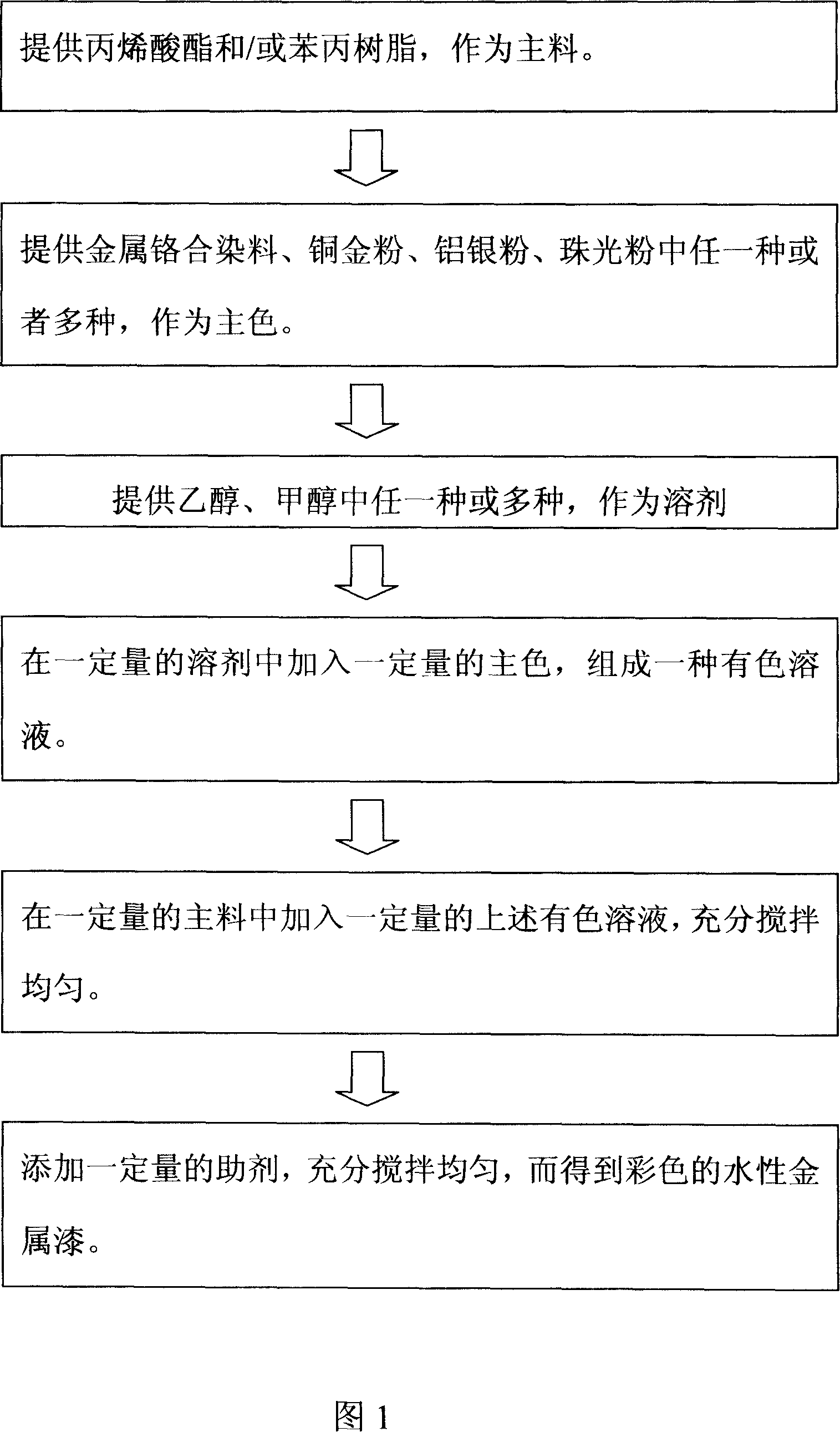

Method for manufacturing chromatic aqueous metallic paint

The invention relates to a production method of a colorful waterborne mental paint. The method comprises the following steps: step 1. acrylate and / or styrene-acrylic resin are / is provided as main material; step 2. any one or more than one mental chromium complex dye, bronze powder, aluminium silver powder and pearls powder is provided as main color; step 3. either ethanol or methanol is provided as solvent; step 4. a certain amount of main color is added in certain amount of solvent to form a colorful solution; step 5. a certain amount of the main material is added in the colorful solution and evenly stirred.

Owner:刘四元

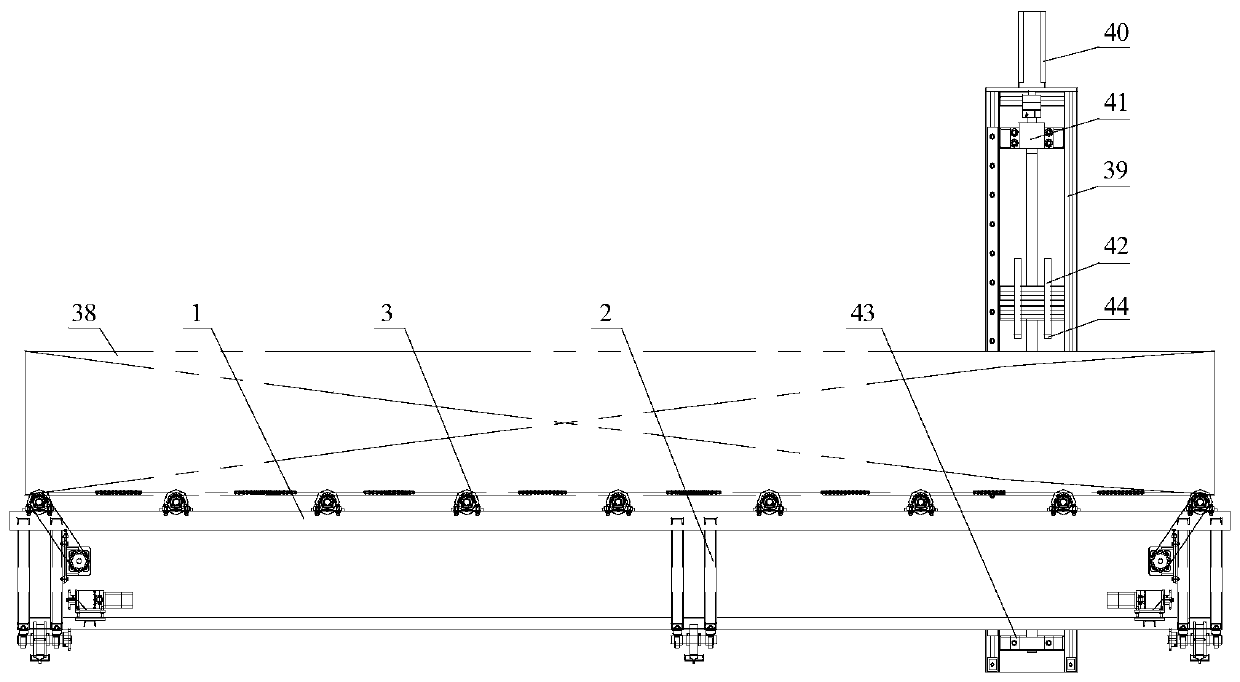

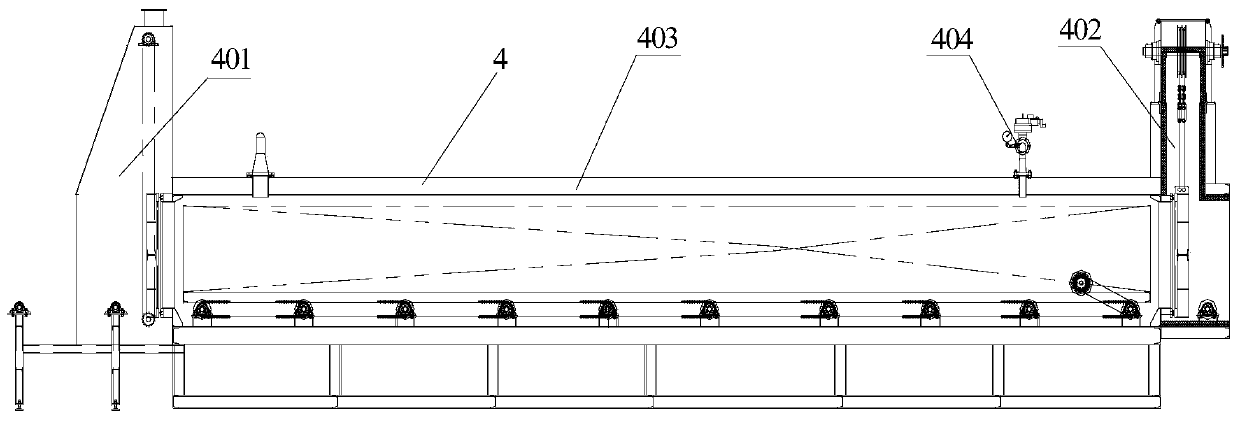

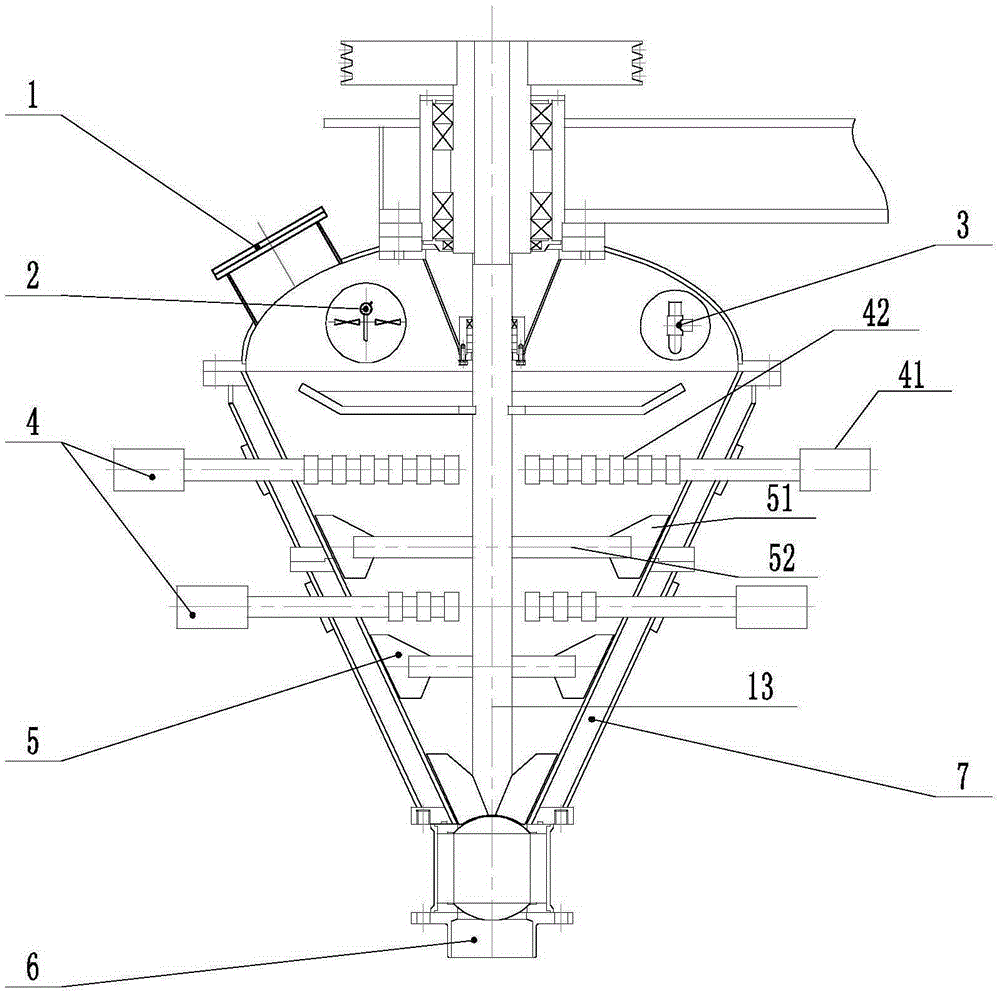

Multi-element gas co-infiltration strengthening system and process thereof

The invention discloses a multi-element gas co-infiltration strengthening system and a process thereof, and belongs to the technical field of workpiece heat treatment. According to the multi-element gas co-infiltration strengthening system and the process thereof, the problems of poor environmental protection, poor infiltration effect and single infiltration layer of traditional heat treatment aresolved. The multi-element gas co-infiltration strengthening system comprises a feeding unit, an air exchange unit, a heating pre-infiltration unit, a multi-element gas co-infiltration strengthening unit, a cooling protection unit and a discharge unit connected in sequence. By means of the multi-element gas co-infiltration strengthening system and a process thereof the, through the cooperation ofeach unit, a traditional acid anticorrosion process is replaced, so that the environmental protection is improved; through the air exchange unit, the air participation is avoided, so that the sufficiency of polyatomic infiltration is improved; through the combination of the heating pre-infiltration unit and microwave radiation, the structure of the surface of a lamp post is changed, so that the infiltration speed and depth of subsequent nitrogen, sulfur and chromium elements are improved; and in the strengthening treatment of multi-element gas co-infiltration, firstly, ammonia atmosphere nitriding treatment is adopted, and then gaseous carbon sulfur chromium complex is released by an accelerating infiltration ball B, so that the carburizing, sulphurizing and chromizing co-infiltration treatment is achieved, the structure of the infiltration layer is complex and diversified, and the hardness of the lamp post is improved.

Owner:江苏良川科技发展有限公司

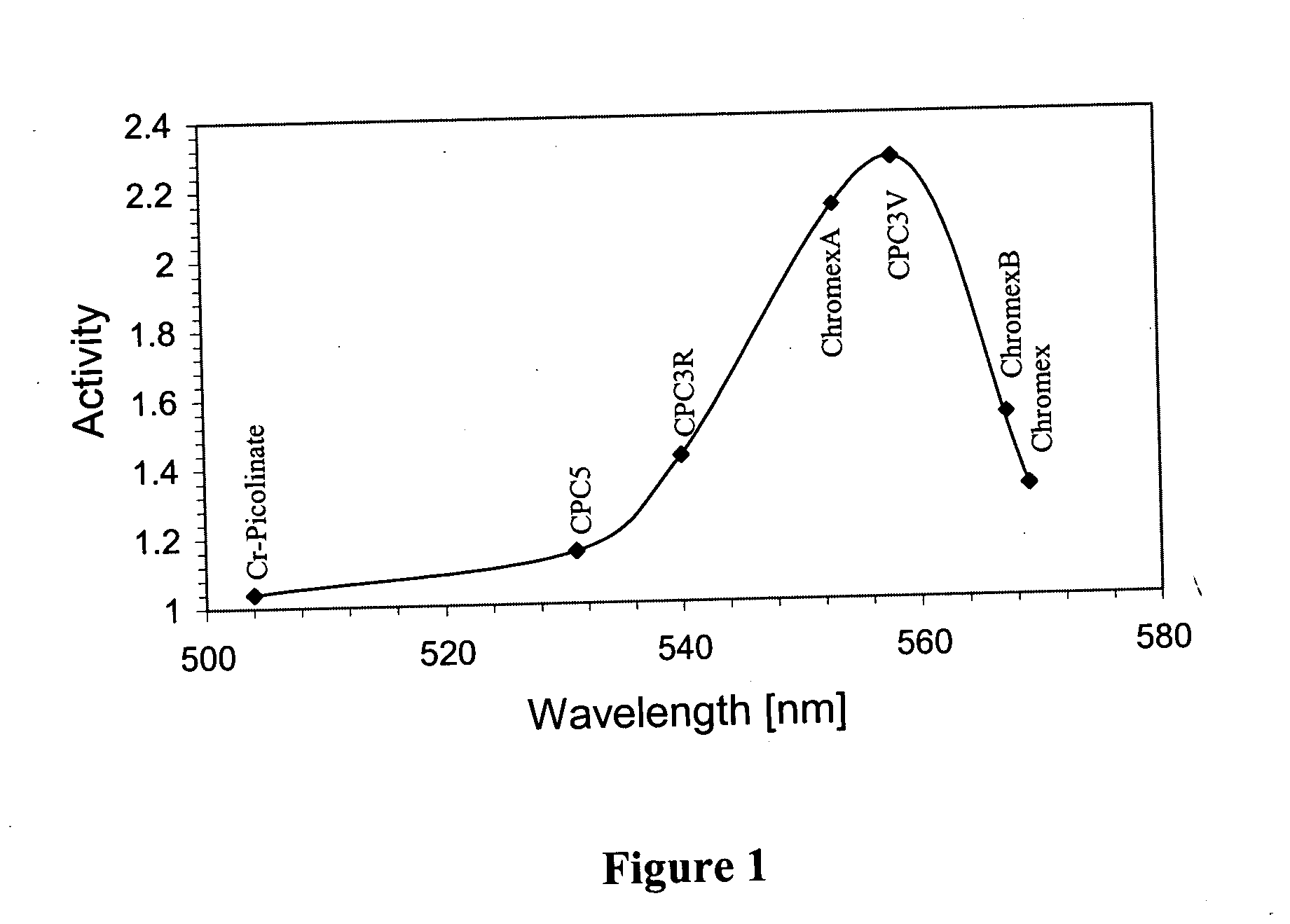

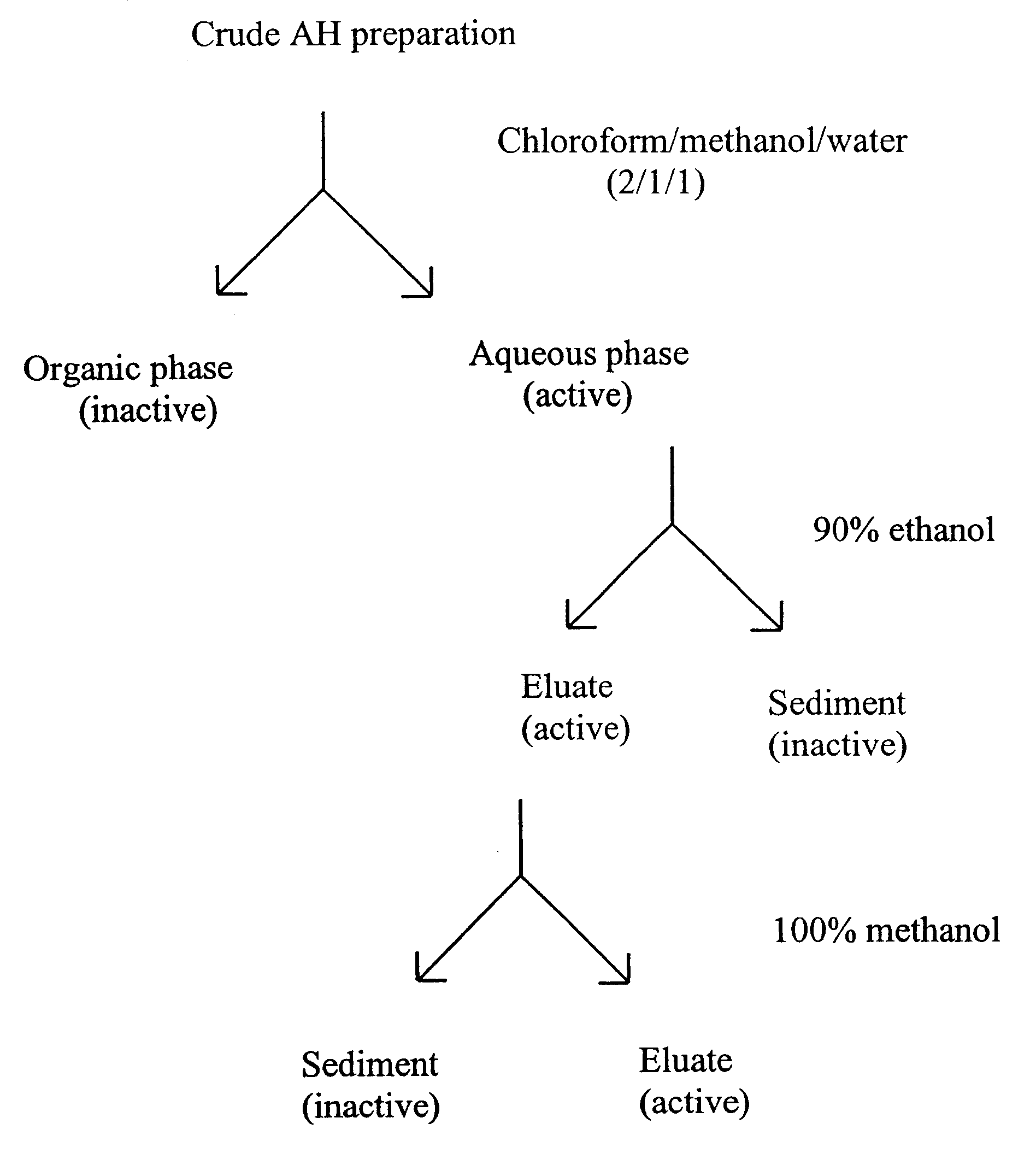

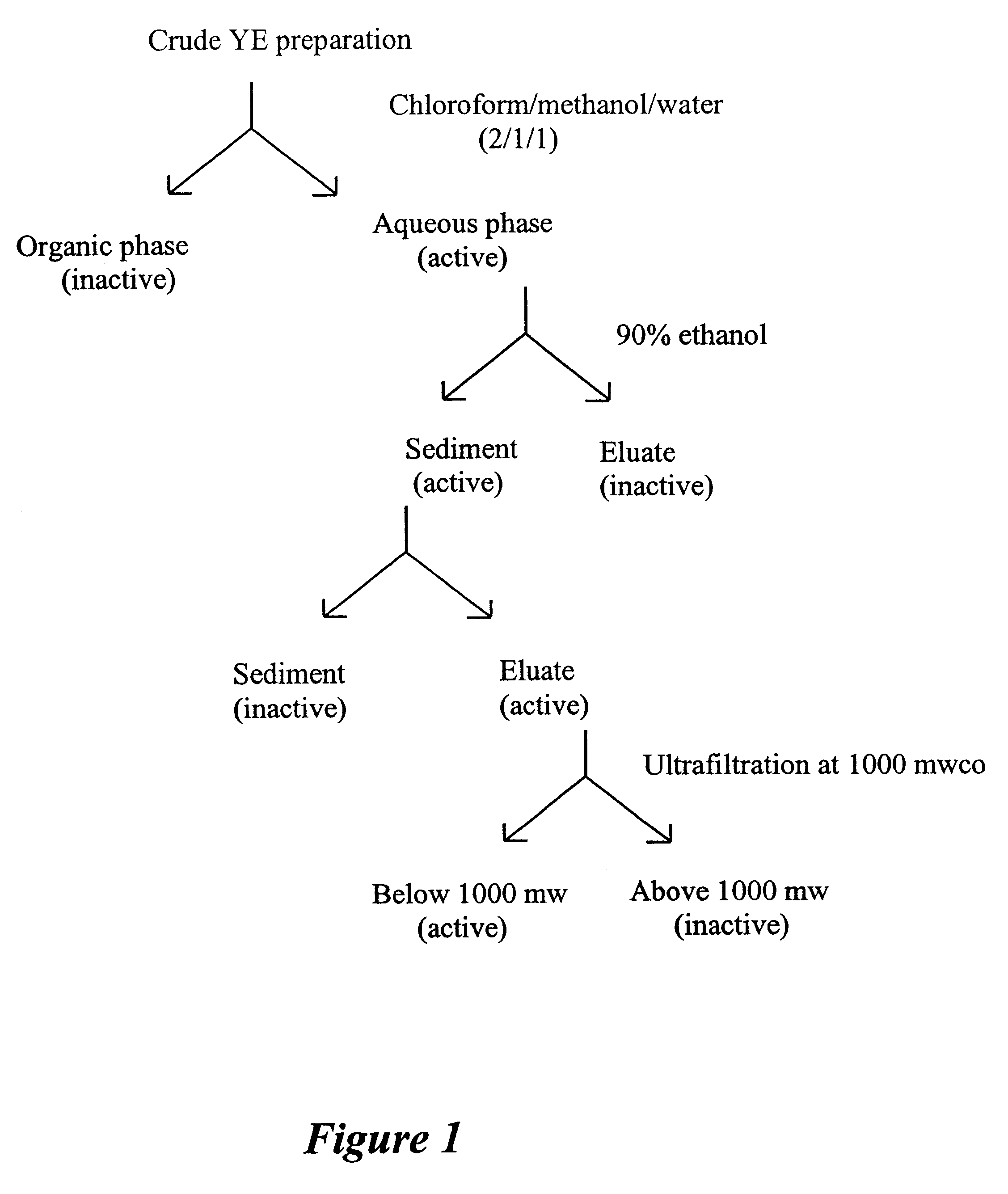

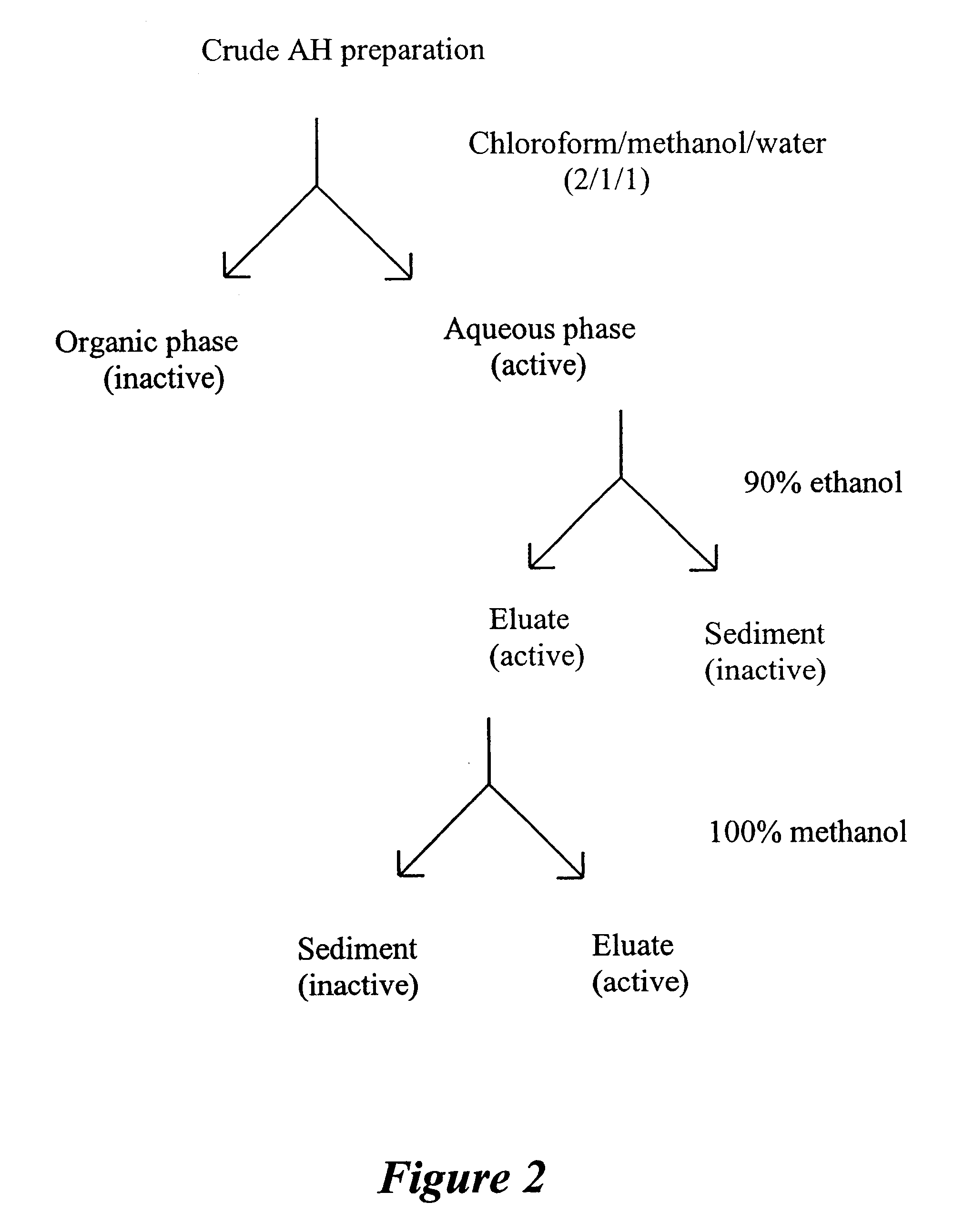

Naturally extracted and synthetic hypoglycemic or hypolipidemic compositions

Compositions having hypoglycemic and / or hypolipidemic activity are isolated from natural sources including yeast and Saltbush (Atriplex halmus). In addition, synthetic chromium complexes were prepared. Compositions possessing hypoglycemic and / or hypolipidemic activity with or without chromium containing natural and synthetic compounds are formulated for use in animals and humans. Methods for use of the compositions alone, or in combination with antioxidant agents, for regulating glucose and lipid levels in diabetes, cardiovascular diseases, inflammatory and cell proliferative diseases and in skin conditions, are presented.

Owner:NATURAL COMPOUNDS

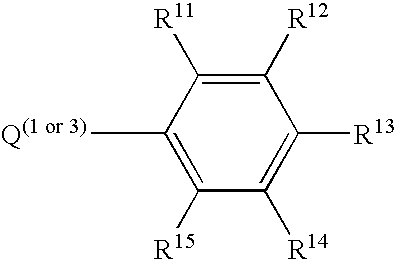

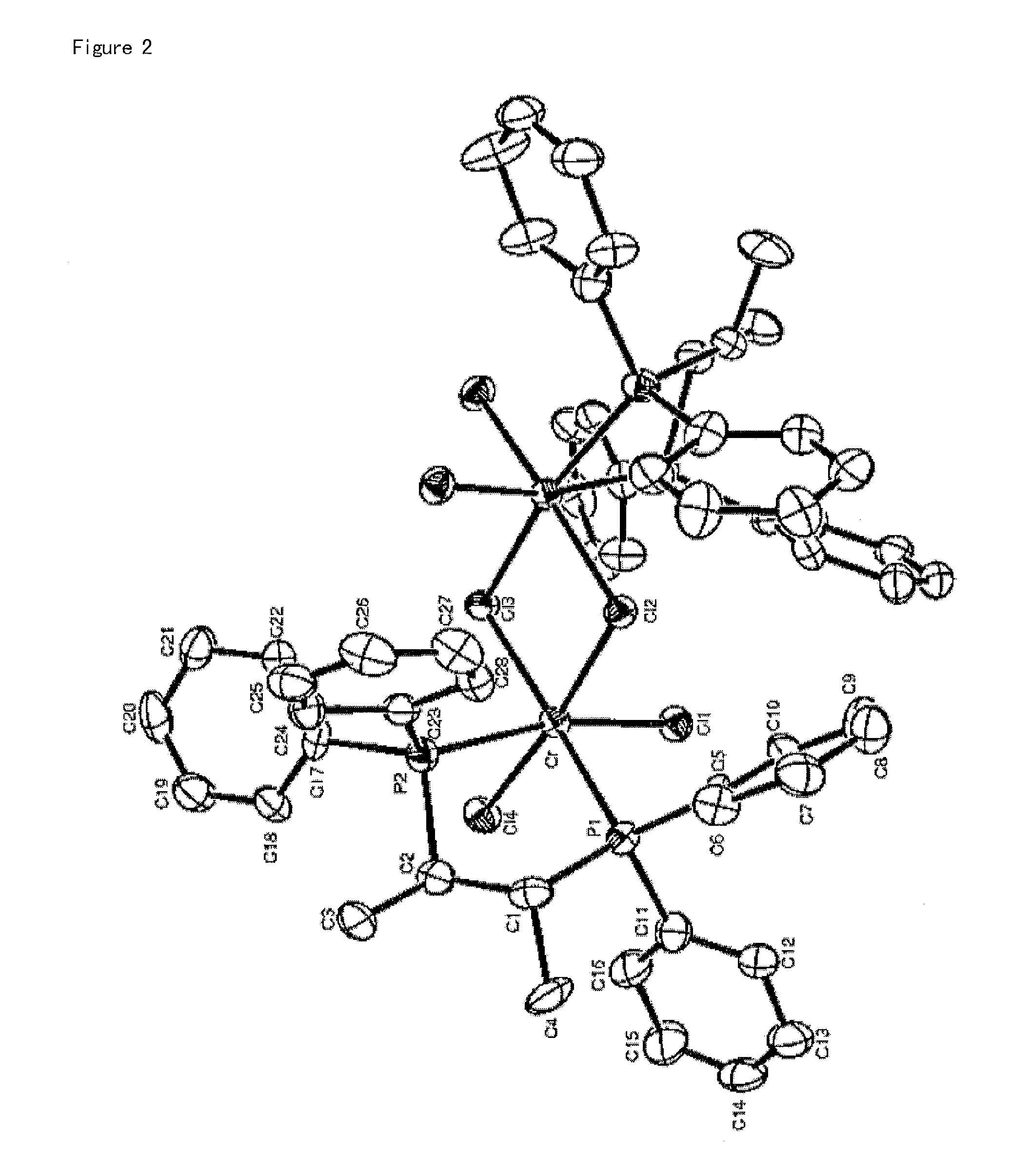

Highly Active and Selective Ethylene Oligomerization Catalyst and Method of Preparing Hexene or Octene Using the Same

ActiveUS20120130086A1High selectivityReduce the amount requiredOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compounds1-OcteneOctene

Owner:SK INNOVATION CO LTD +1

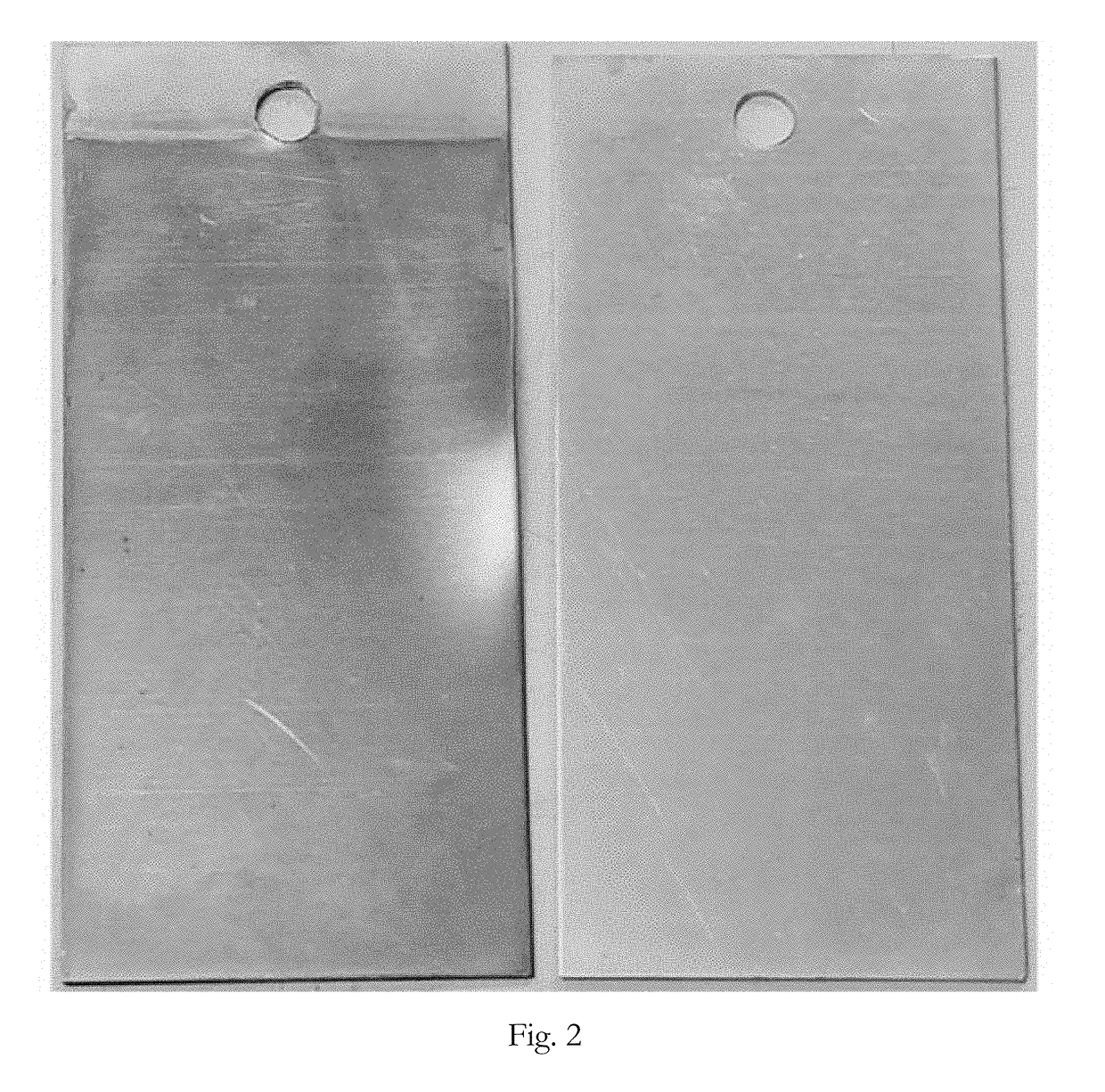

Dyed trivalent chromium conversion coatings and methods of using same

ActiveUS20180216234A1Less susceptible to corrosion and/or other undesirable reactionsEasy to seeAnti-corrosive paintsMetallic material coating processesChromium CompoundsSulfate

An aqueous conversion coating solution comprises a trivalent chromium compound, a zirconate compound, and a dye compound. The trivalent chromium compound can comprise trivalent chromium compounds such as trivalent chromium sulfate. The dye compound can comprise an azo dye, a chromium complex dye, an anthraquinoid dye, and / or a methine dye. The zirconate compound can comprise alkali metal hexafluorozirconate compounds. The conversion coating solution can comprise a phosphorous compound such as an organic amino-phosphonic acid compound. The conversion coating solution can be formed by mixing a dye additive containing the dye with a trivalent chromium conversion coating solution that does not contain a dye. The conversion coating solution can be used to treat metal substrates comprising aluminum, magnesium, and / or zinc.

Owner:CHEMEON SURFACE TECH LLC

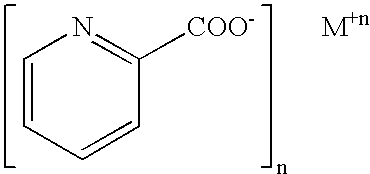

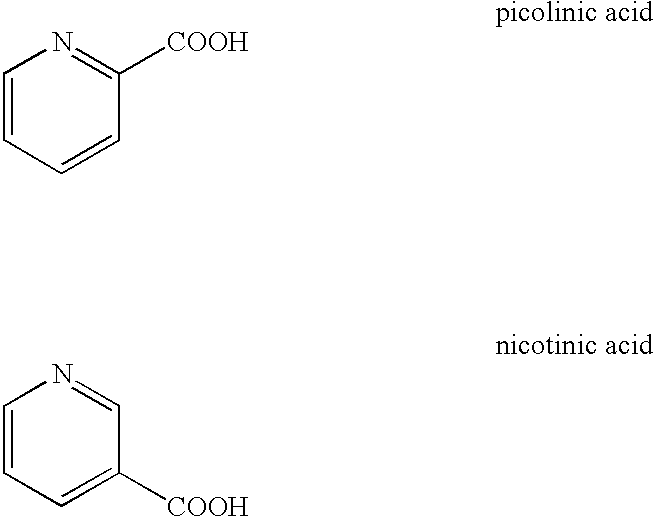

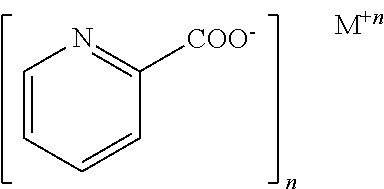

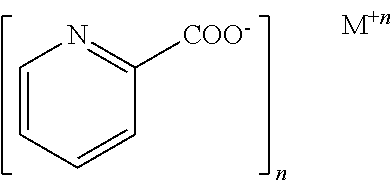

Methods and compositions for the benefit of those suffering from polycystic ovary syndrome with chromium complexes

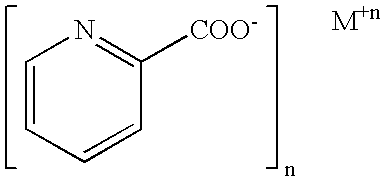

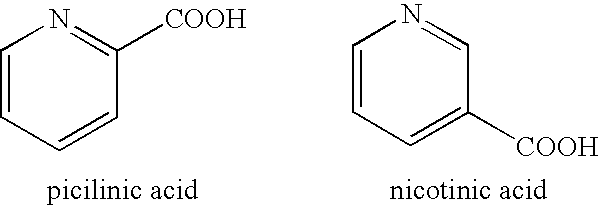

Compositions comprising chromium complexes such as chromium picolinate or chromium nicotinate are administered to a subject presenting with Polycystic Ovary Syndrome. The compositions may further comprise at least one of a chelating agent, cyclooxygenase inhibitor, a mucolytic, and / or a salicin-containing herb.

Owner:AMBI

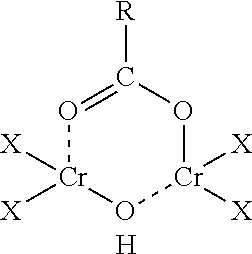

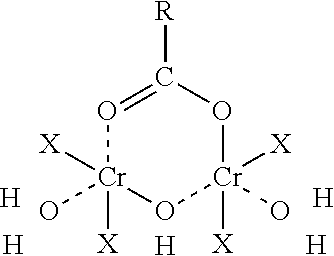

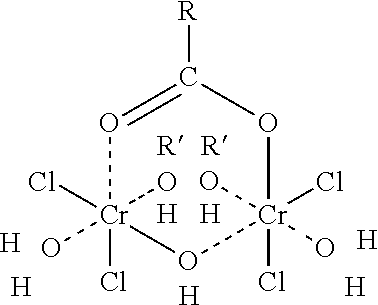

Time-release compositions for delivery of [Cr3O(carboxylate)6(H2O)3]+

A time release composition is provided containing:a chromium complex having formula 3[Cr3O(carboxylate)6(ligand)3]+ (3)wherein carboxylate is a C2-C5 alkyl carboxylate and wherein ‘ligand’ is a ligand that (i) renders the chromium complex insoluble or only slightly soluble in water and (ii) is acid labile, being readily displaced under acidic conditions below pH=4 and replaced by water to make the resulting water soluble complex 2[Cr3O(carboxylate)6(H2O)3]+, (2)and the use of the time release composition for the time release delivery of complex 2.

Owner:UNIVERSITY OF ALABAMA

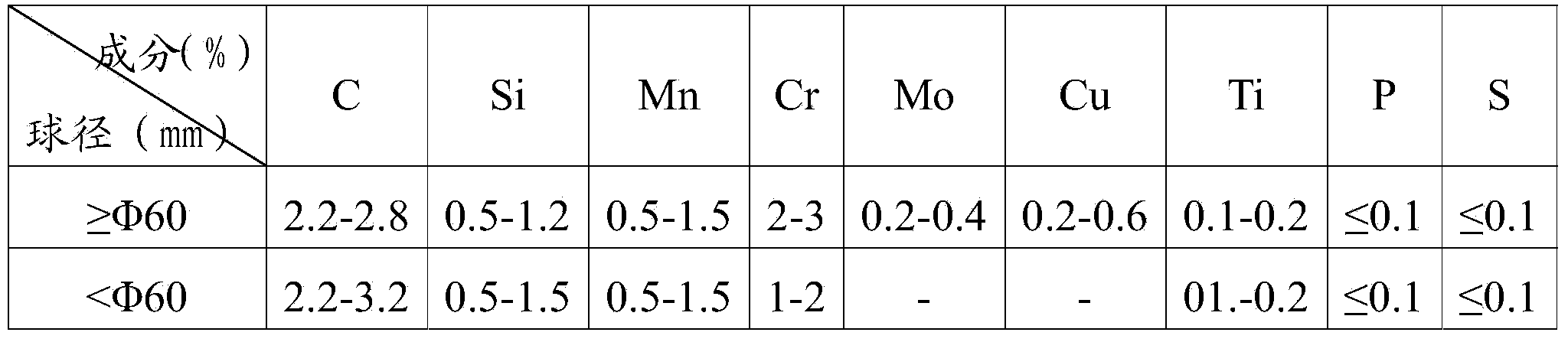

Process for producing low-chromium complex alloy grinding ball

InactiveCN103725950AImprove internal and external qualityImprove impact performanceFoundry mouldsFoundry coresChemical compositionAlloy

The invention relates to a process for producing a low-chromium complex alloy grinding ball. The process comprises the steps of melting, pouring, casting a metal mold and tempering, chemical components of the low-chromium complex alloy grinding ball are reasonably designed, and metal mold casting and tempering are carried out, so that the internal and external quality of the grinding ball can be improved, the product does not have the casting defects, such as sinkholes, pores, looseness and the like, the broken rate and no circularity of the grinding ball can be reduced, the fatigue impact resistance and wear resistance of the grinding ball can be improved, the product yield can be remarkably improved, the production process can be simplified, and the production cost can be reduced.

Owner:南平市双友金属有限公司

Super-hydrophobic composition, preparation of same and super-hydrophobic paper

InactiveUS20150075407A1Other chemical processesSemiconductor/solid-state device manufacturingCHROMIUM COMPLEXInorganic nanoparticles

A super-hydrophobic composition for layer recovering, particularly paper, in which the composition is a mixture of at least one hydrophobic agent of chromium complex and inorganic nanoparticles selected from a group consisting of hydrophobic nanoparticles, hydrophilic nanoparticles and combinations thereof, with an average particle size of 1 nm to 35 nm.

Owner:COPAMEX DE C V

Use of chromium complex in the leather industry

InactiveUS20090158530A1Improve efficiencyReduce loadTanning treatmentCHROMIUM COMPLEXLeather industry

This invention is related to the manufacturing process of the modified chromium sulphate used in the tanning process of the animal hides, and chromium tanning process performed by using the said chemical.This invention developsManufacturing processes of chromium tanning chemical which do not require pickling and basification;Chromium and tanning chemical produced according to this process; andChromium tanning processes which use the said chemical and do not require pickling and basification.As a result of the reaction of the chromium salts mentioned in the invention with mono and dicarboxyllic acids or salts of these acids, characteristics of the chromium salts change; thereby the invention provides benefits such as the elimination of the pickling and the basification process, minimization of the waste treatment burden and acceleration of the said processes in the tannery.

Owner:SODA SANAYI A S

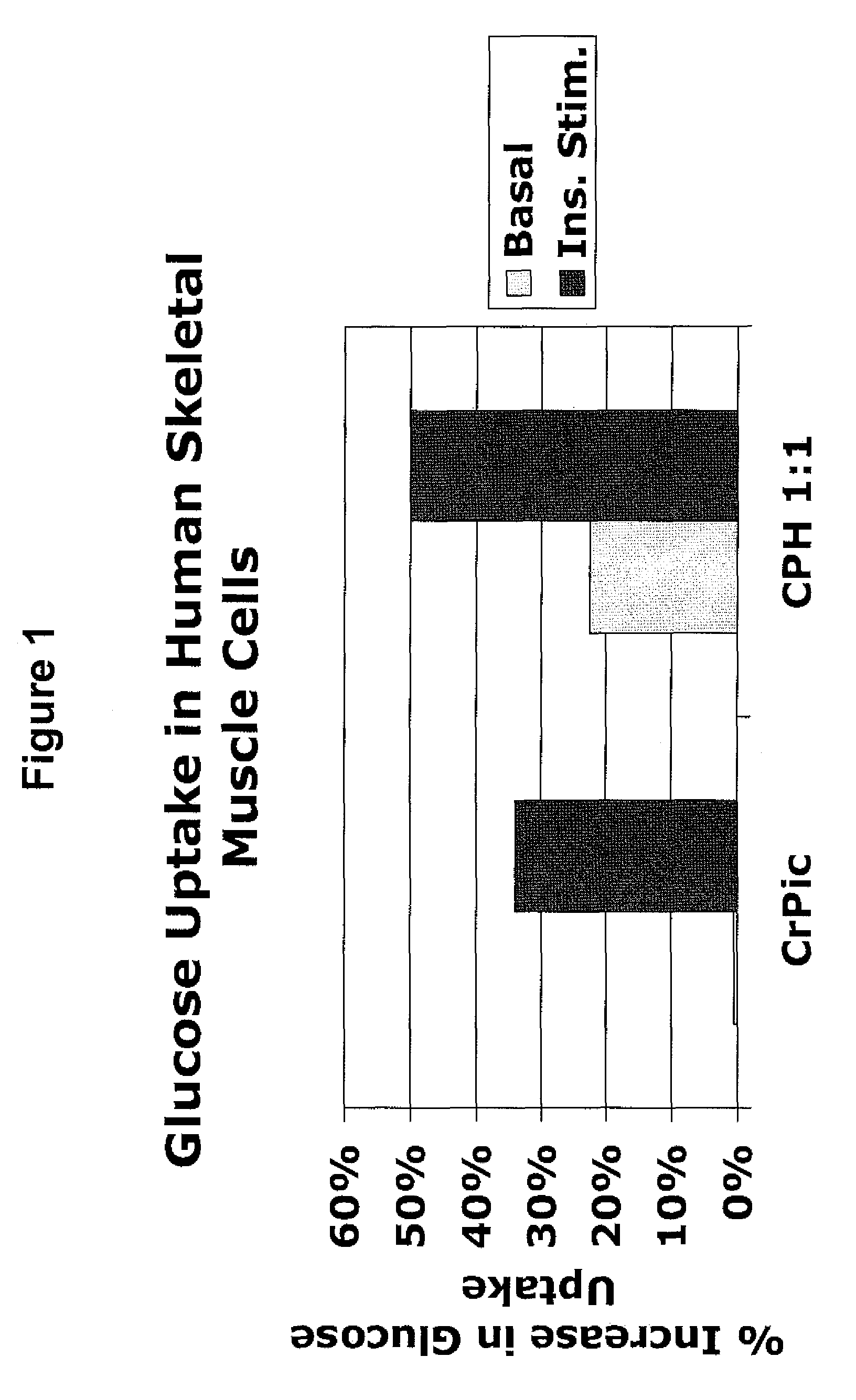

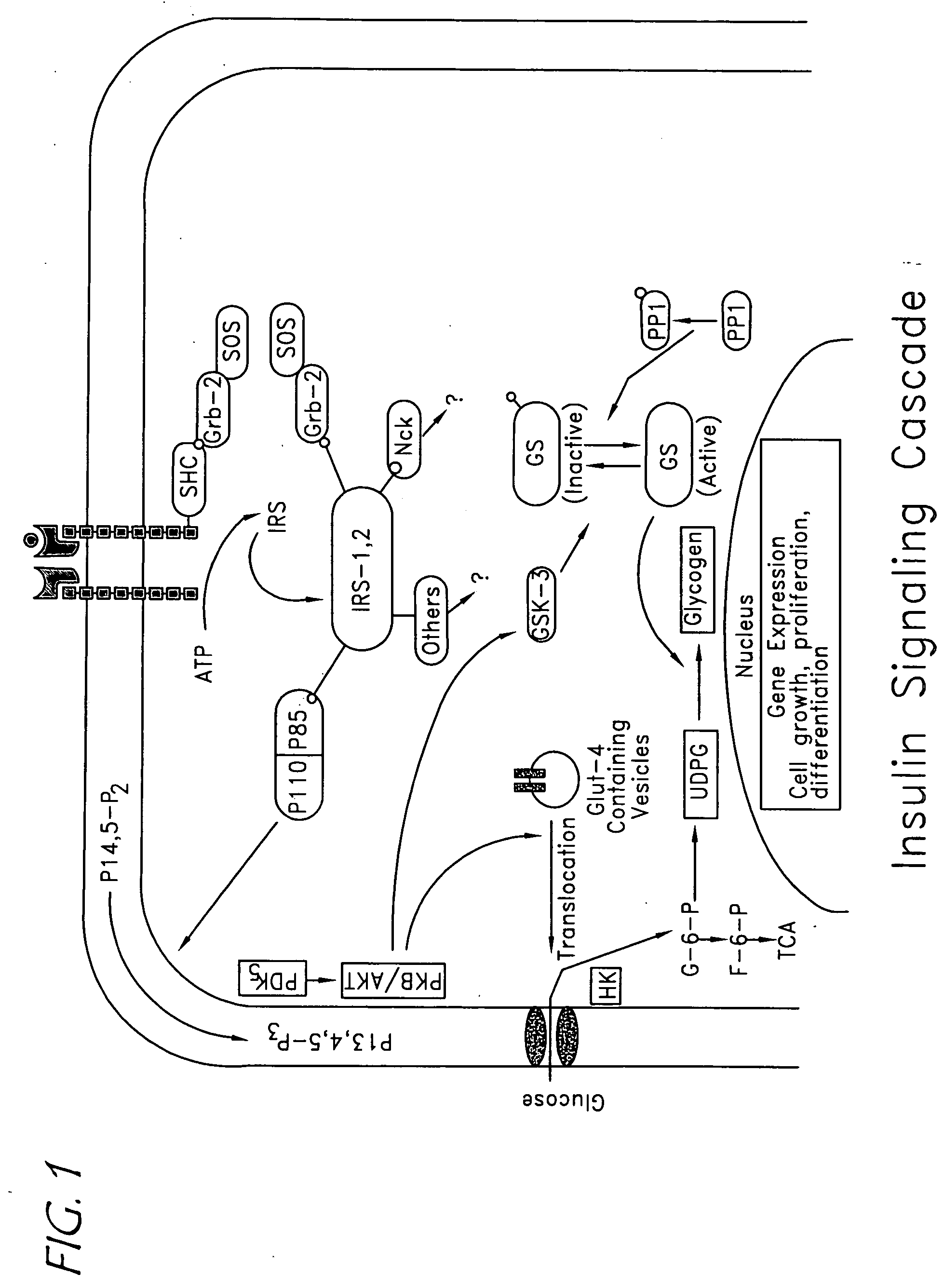

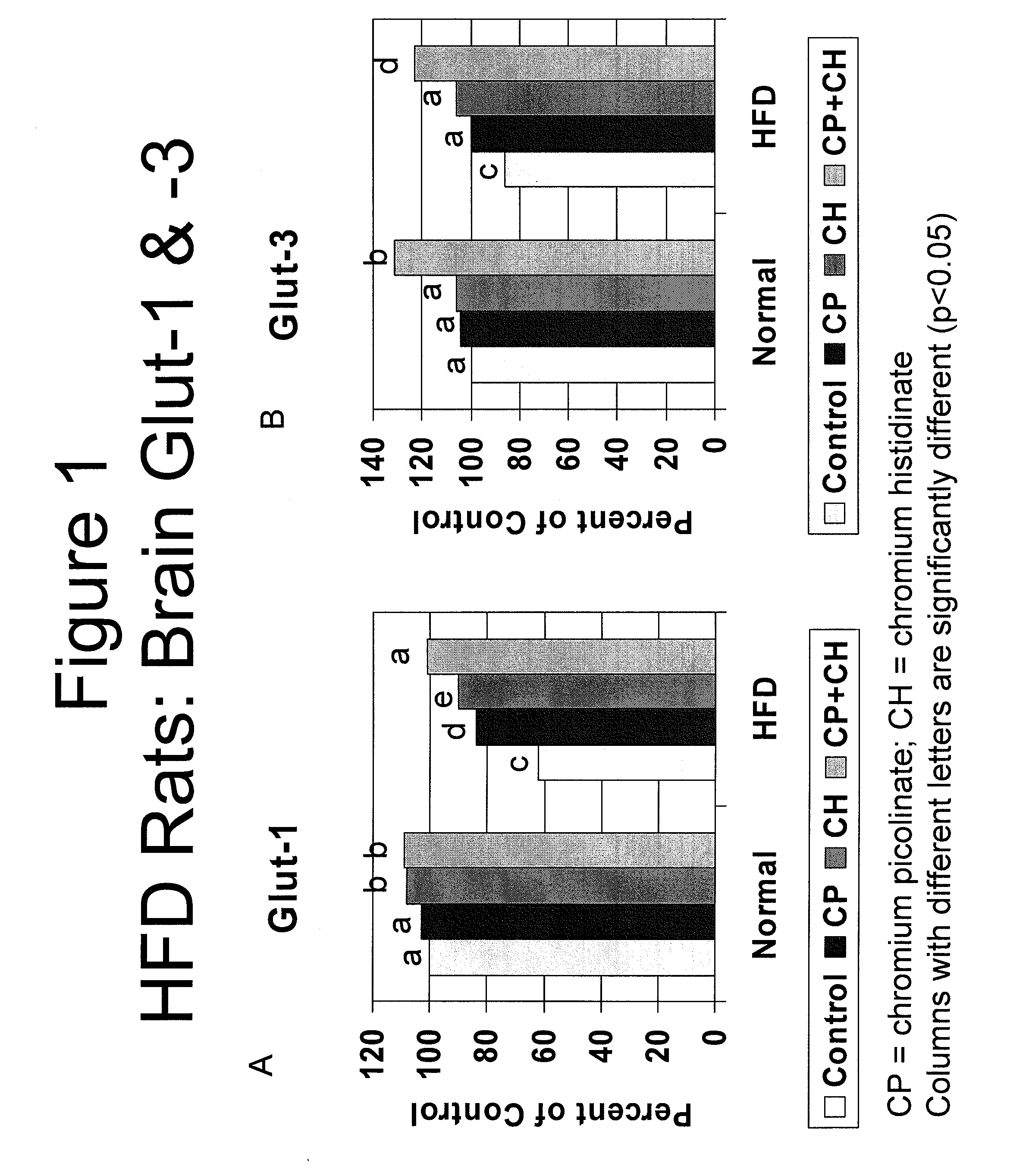

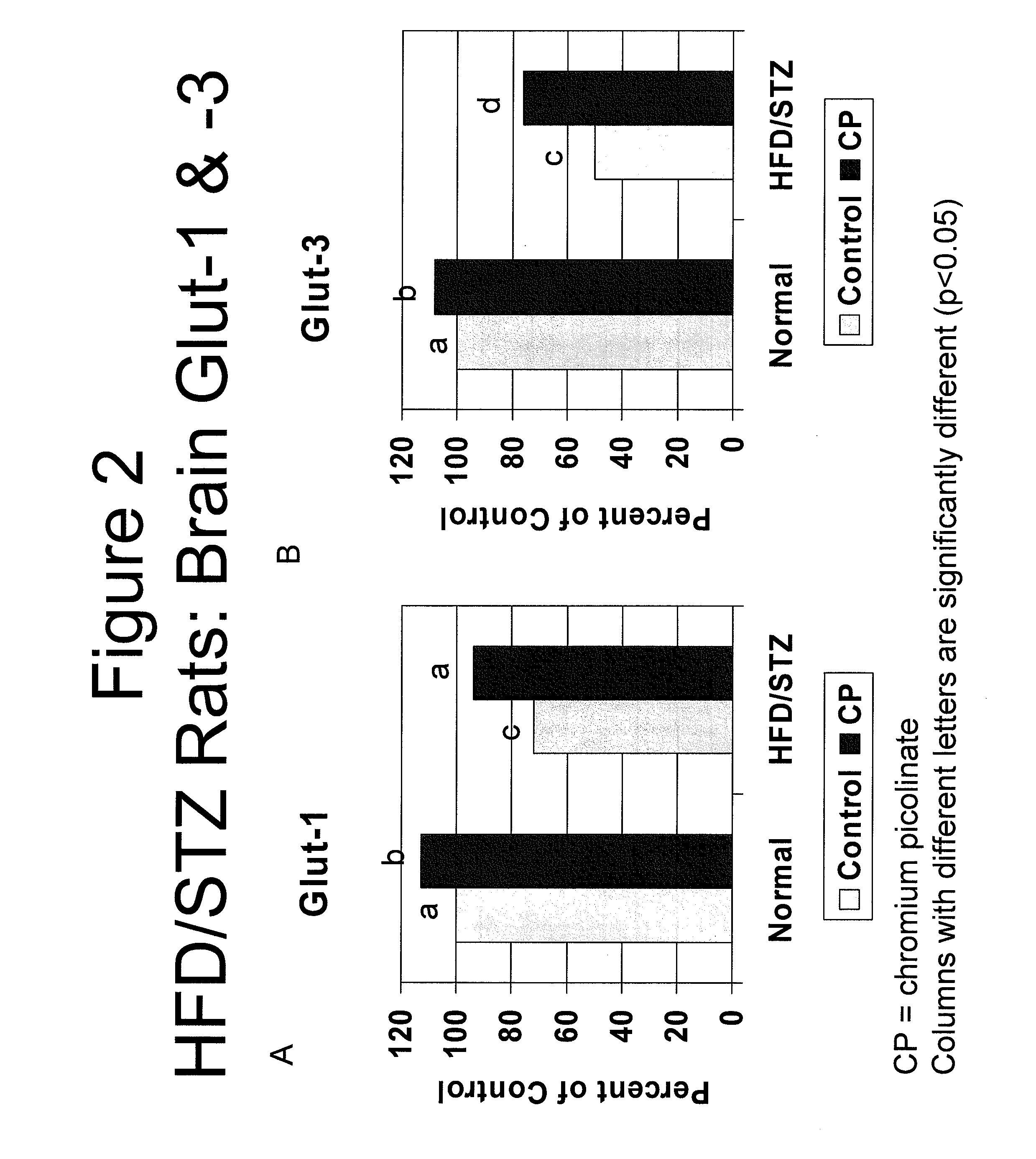

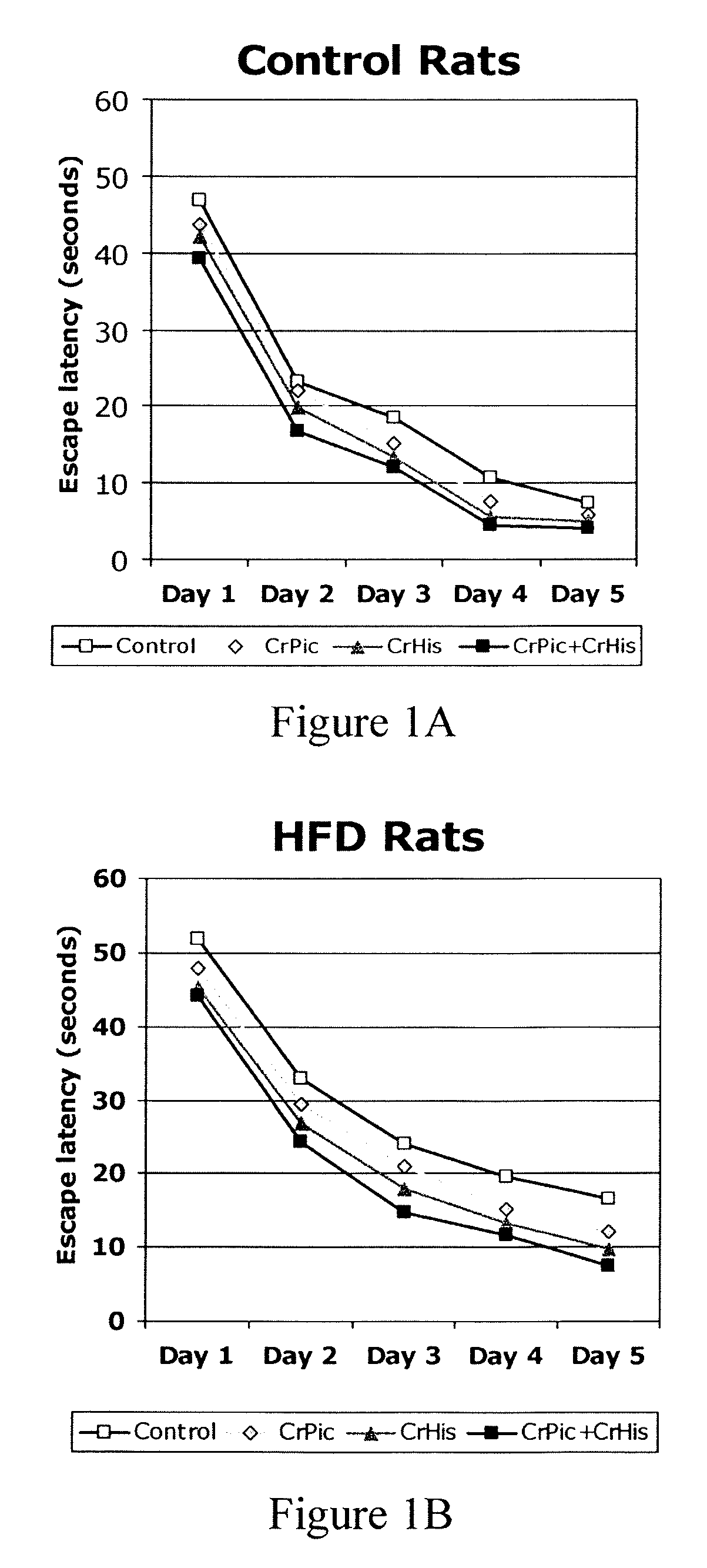

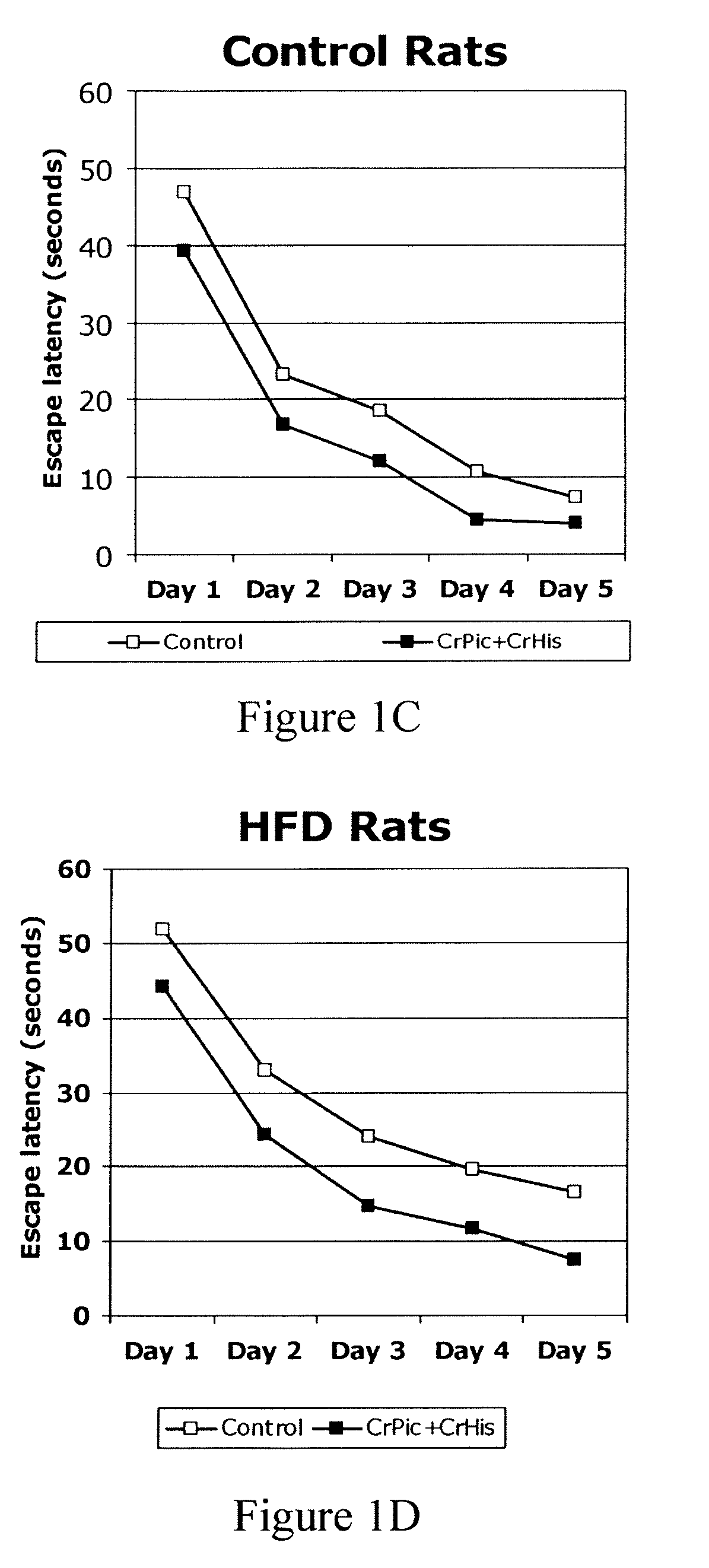

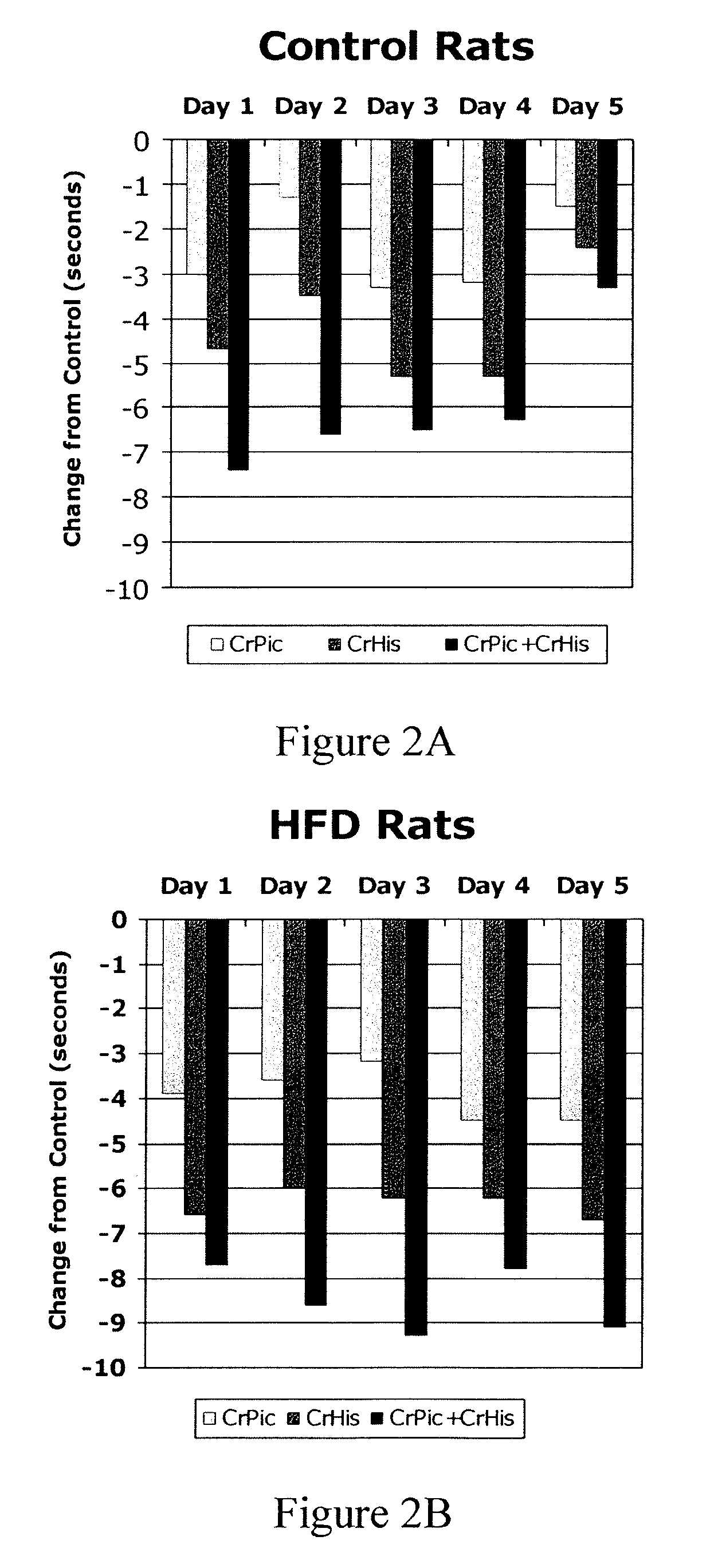

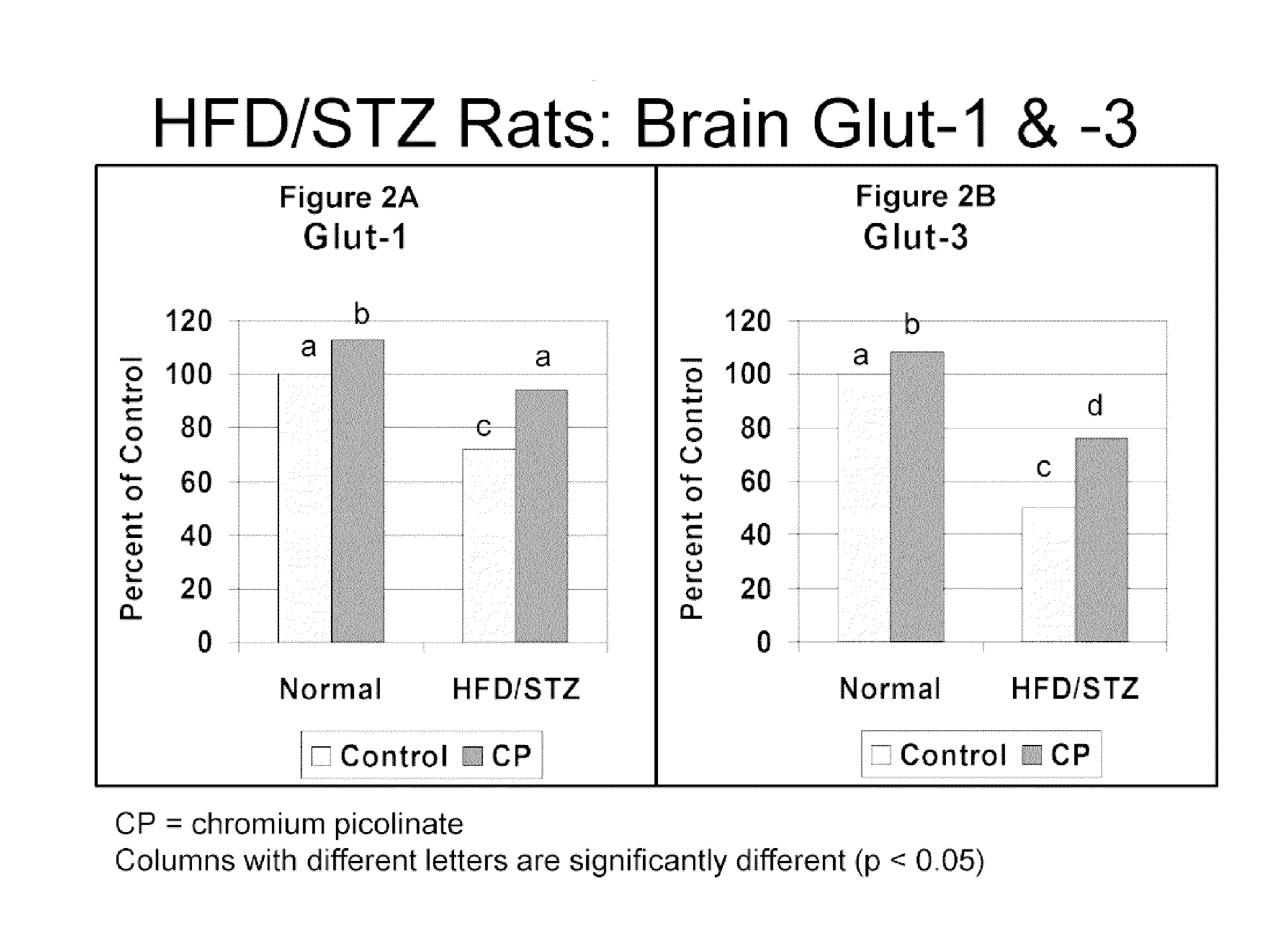

Chromium complexes as enhancers of brain glucose transporters

ActiveUS20120100228A1Increase brain glucose transporterLower Level RequirementsOrganic active ingredientsHeavy metal active ingredientsDiseaseMedicine

The embodiments disclosed herein relate to compositions for enhancing brain glucose transporters, such as GLUT1 and GLUT3, and methods of treating and / or preventing diseases or disorders associated with the regulation GLUT1 and GLUT3. Also provided are compositions that include chromium and an agent that targets the brain or the central nervous system. Further provided are improved methods of delivering therapeutic agents that target the brain and / or central nervous system.

Owner:NUTRITION 21 INC

Chromium complexes for improvement of memory and cognitive function

InactiveUS20100178362A1Shorten the progressReduce functionHeavy metal active ingredientsBiocideMild cognitive impairment (MCI)Psychiatry

A method of treating impaired memory and / or cognitive function by administering one or more chromium complexes, for example chromium picolinate, to an individual in need of improved memory and / or cognitive function. This method is used to improve memory and / or cognitive function associated with various disorders, including Alzheimer's disease, dementia, and mild cognitive impairment (MCI). Chromium complexes for treating memory or cognitive impairment are also disclosed.

Owner:NUTRITION 21 INC

Chromium complexes as enhancers of brain glucose transporters

InactiveUS20150224140A1Lower Level RequirementsEnhancing brain glucose transportersHeavy metal active ingredientsOrganic active ingredientsDiseaseMedicine

The embodiments disclosed herein relate to compositions for enhancing brain glucose transporters, such as GLUT1 and GLUT3, and methods of treating and / or preventing diseases or disorders associated with the regulation GLUT1 and GLUT3. Also provided are compositions that include chromium and an agent that targets the brain or the central nervous system. Further provided are improved methods of delivering therapeutic agents that target the brain and / or central nervous system.

Owner:NUTRITION 21 INC

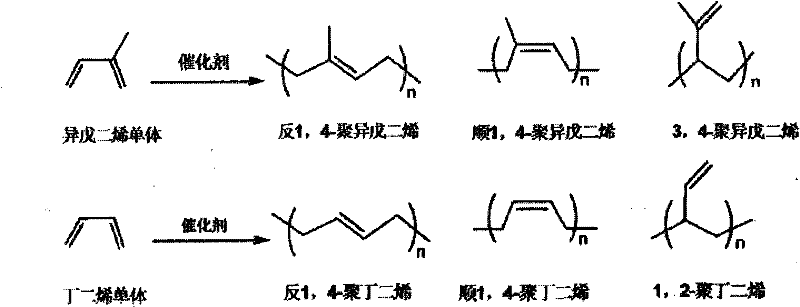

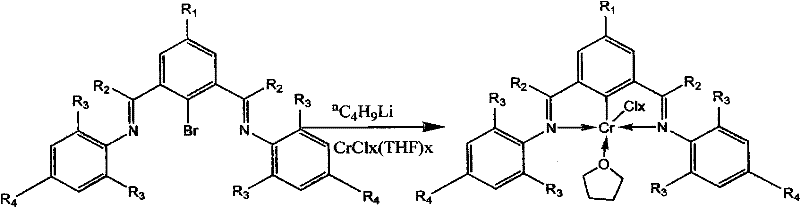

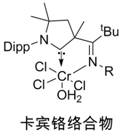

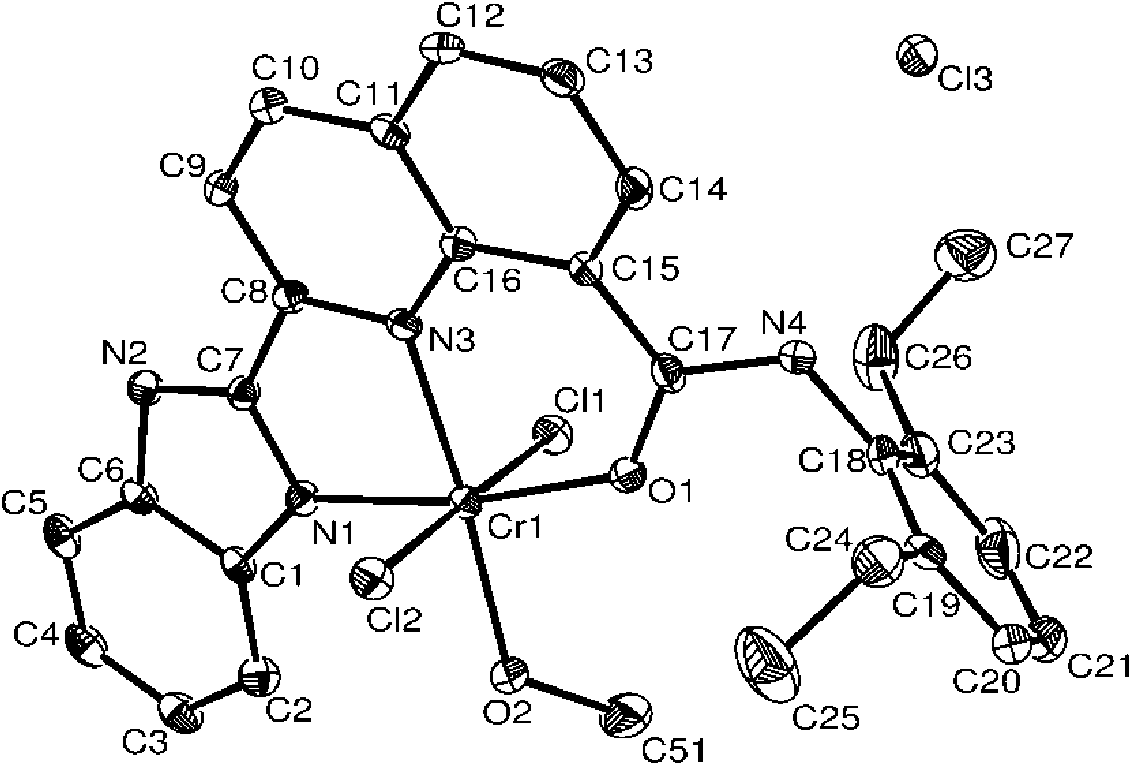

Caliper type chromium complex and preparation method and application thereof

InactiveCN102127116AImprove stabilityGood stability and easy preparationGroup 6/16 element organic compoundsButyl lithiumAdduct

The invention relates to a caliper type chromium complex and a preparation method and application thereof, and belongs to the technical field of catalysts. The caliper type chromium complex is a [NCN]-ligand-based caliper type chromium complex. The preparation method comprises the following steps of: adding hexane solution of butyl lithium into tetrahydrofuran solution of a ligand dropwise for reaction; adding a tetrahydrofuran adduct of chromium trichloride or chromium dichloride; and heating the mixture to room temperature naturally and reacting to obtain the caliper type chromium complex. The ligand can be 2,6-bis(N-2,6- phenyl)imido bromobenzene. The caliper type chromium complex, alkyl aluminum and organic boron salt serving as catalysts are used for catalyzing selective polymerization of isoprene or butadiene. The caliper type chromium complex has high stability and is convenient to prepare; the catalytic system can be used for selectively catalyzing polymerization of the isoprene or the butadiene, and has low using amount of a cocatalyst, high polymerization speed, high conversion rate and high anti-1,4 selectivity; and the caliper type chromium complex can be applied actually by replacing natural trans-1,4 rubber.

Owner:JILIN UNIV

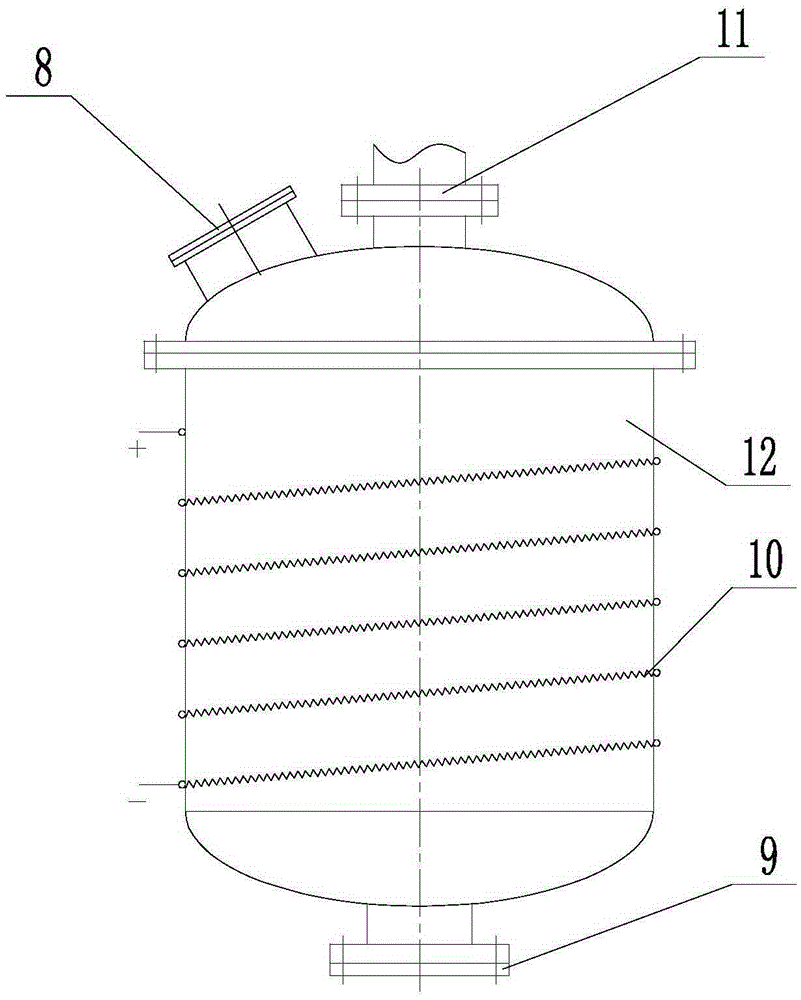

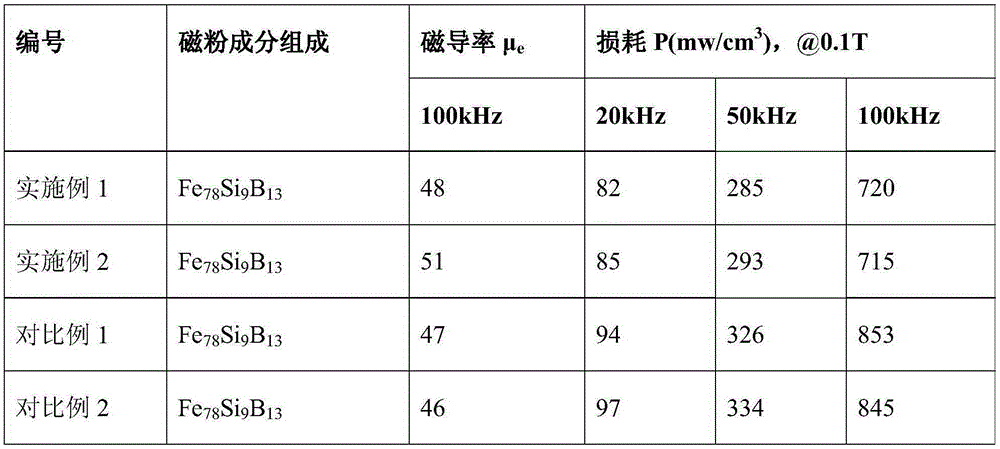

Insulating binder for coating amorphous and nanocrystalline magnetic powder and coating method

InactiveCN105261436AImprove performanceImprove permeabilityInorganic material magnetismInductances/transformers/magnets manufactureSilanesThermal stability

The invention discloses an insulating binder for coating amorphous and nanocrystalline magnetic powder. The insulating binder comprises an inorganic binder, an inorganic binder and a surface modification material, wherein the surface modification material is one or more of an organic chromium complex, silanes, titanate esters and an aluminate compound. The invention further discloses a method for carrying out coating on the amorphous and nanocrystalline magnetic powder by the insulating binder. The method comprises a pretreatment step, a primary baking step, a powder insulating coating treatment step and a secondary drying step. According to the insulating binder and the coating method disclosed by the invention, the overall performance of an amorphous and nanocrystalline magnetic powder core is improved; and the insulating binder has the advantages of high magnetic conductivity and low loss at a high frequency; and in addition, the amorphous and nanocrystalline magnetic powder core obtained by the method has excellent heat stability and mechanical strength.

Owner:北京电力自动化设备有限公司

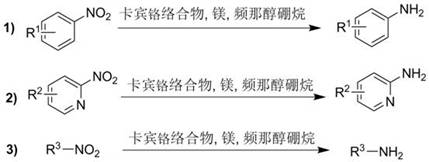

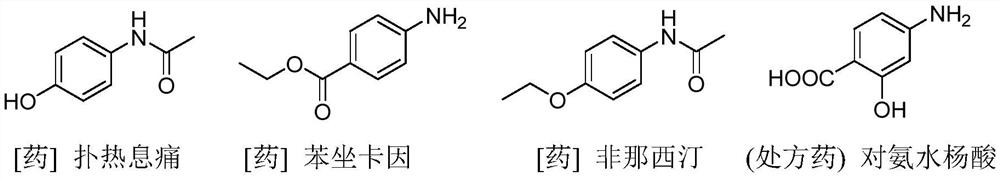

Method for preparing amine through catalytic reduction of nitro compound by cyclic (alkyl) (amino) carbene chromium complex

ActiveCN112661653ALow priceHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitro compoundReduction of nitro compounds

The cyclic (alkyl) (amino) carbene chromium complex is prepared from corresponding ligand salt, alkali and CrCl3 and used for catalyzing pinacol borane to reduce nitro compounds in an ether solvent under mild conditions to generate corresponding amine. The method for preparing amine has the advantages of cheap and accessible raw materials, mild reaction conditions, wide substrate application range, high selectivity and the like, and is simple to operate.

Owner:SICHUAN UNIV

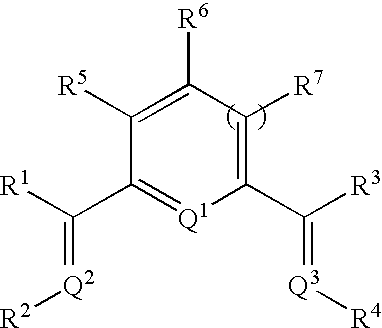

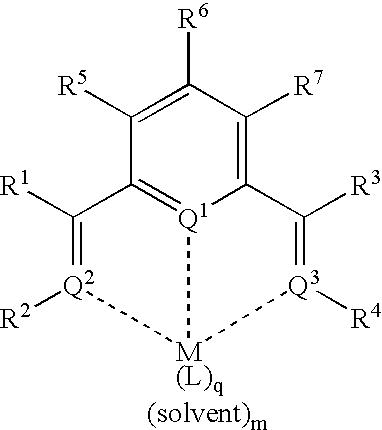

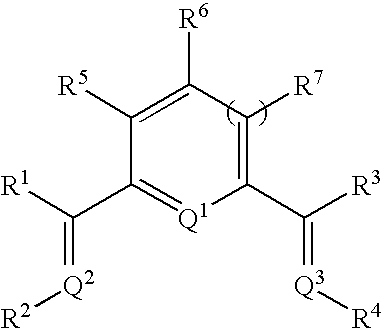

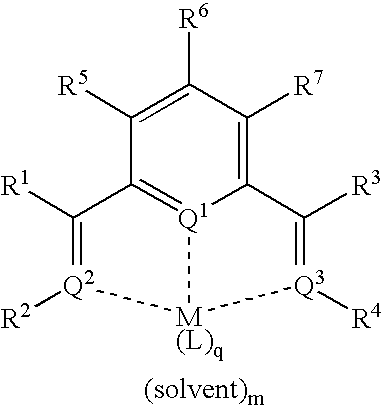

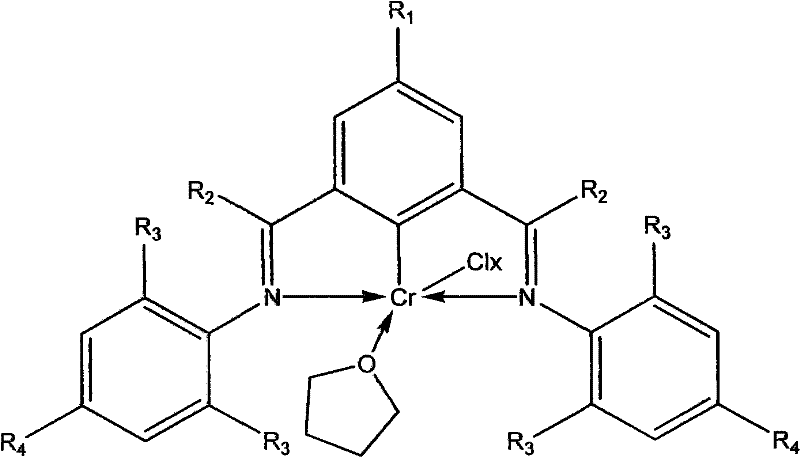

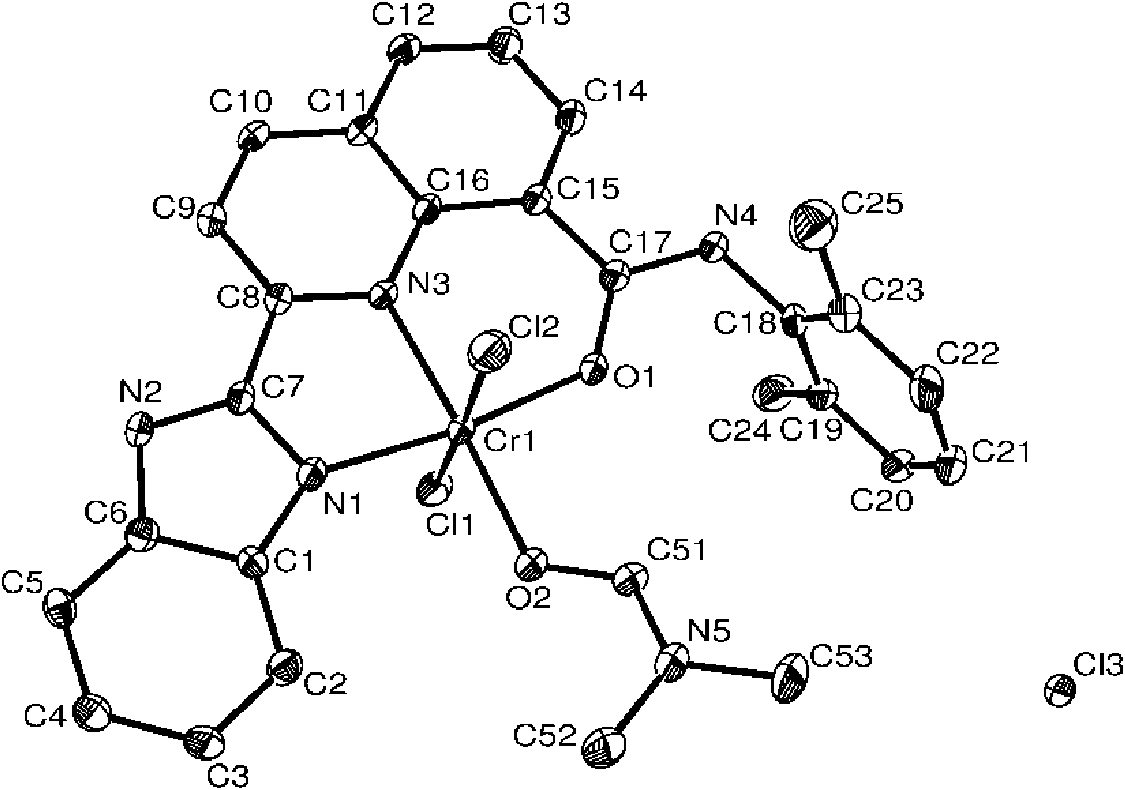

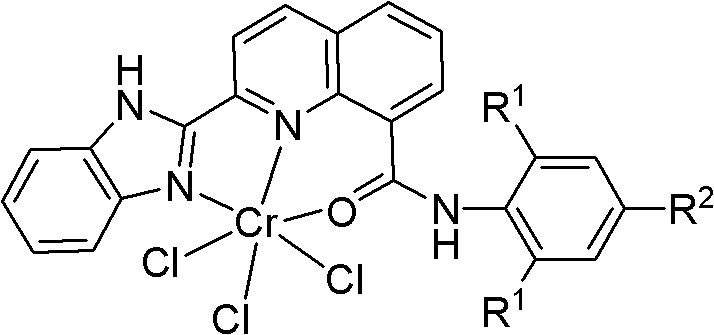

2-benzimidazolyl-8-methanamide quinoline chromium complexes, its preparation method and application

InactiveCN102199173AHigh catalytic activityLarge space for decorationGroup 6/16 element organic compoundsBulk chemical productionQuinolineChloride

The invention discloses 2-benzimidazolyl-8-methanamide quinoline chromium complexes, its preparation method and an application. The structure general formula of the complexes is disclosed as a formula (I). The complexes of the invention are obtained through a reaction by mixing 2-benzimidazolyl-8-methanamide quinoline ligand with tetrahydrofuran chromium chloride. The combination of the complexes and a cocatalyst can be used as a catalyst of ethylene polymerization. The complexes provided by the present invention has the advantages of simple raw materials with low price, easy realization of all the steps and high yield as well as large space for modifying a ligand, and the effects of different ligand environment on catalytic activities can be conveniently researched. The catalyst composition has high catalytic activity to ethylene, and has important application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

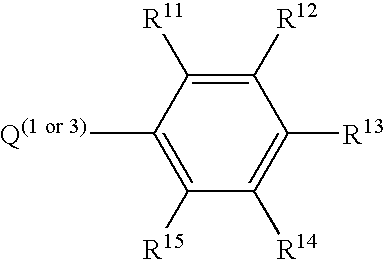

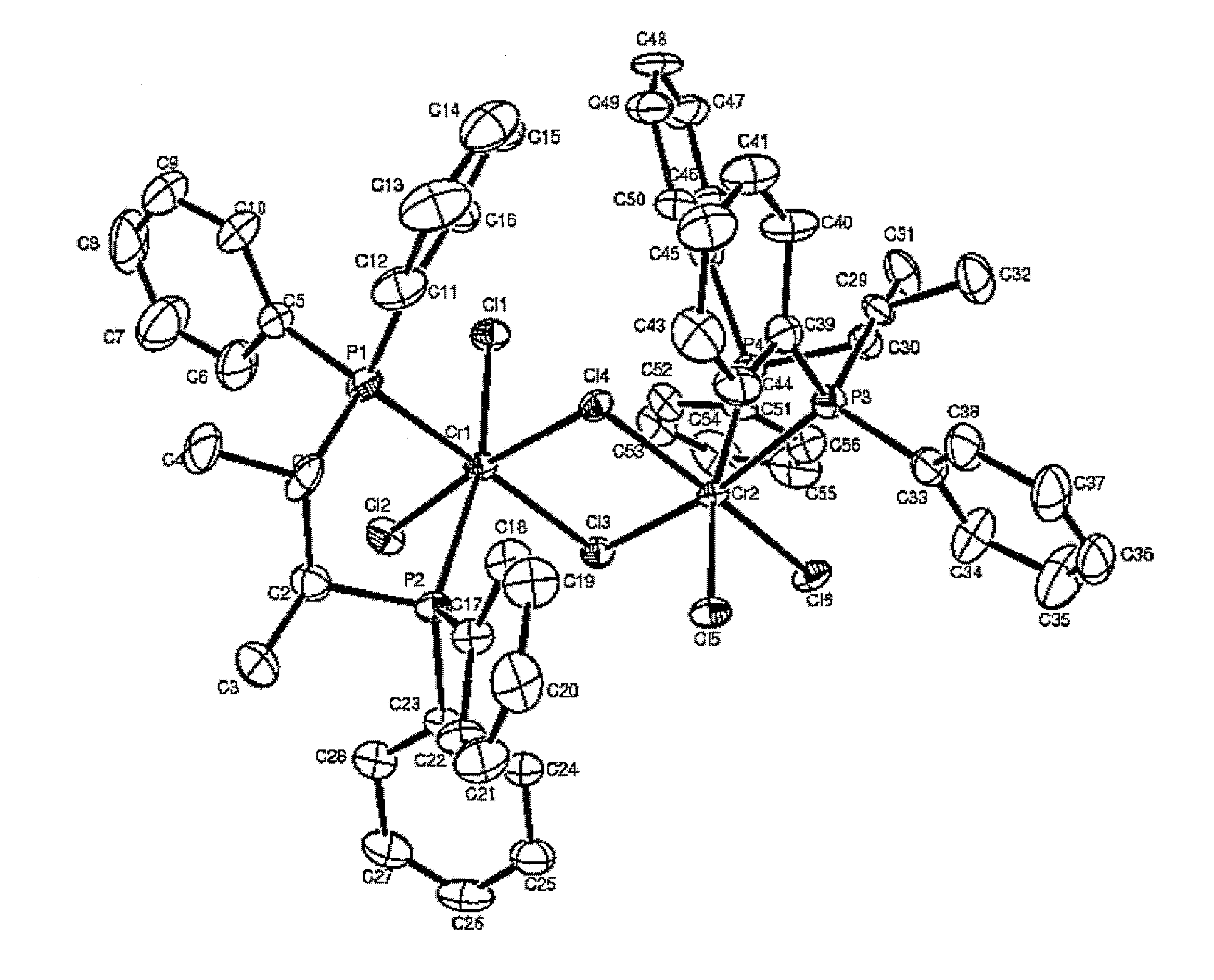

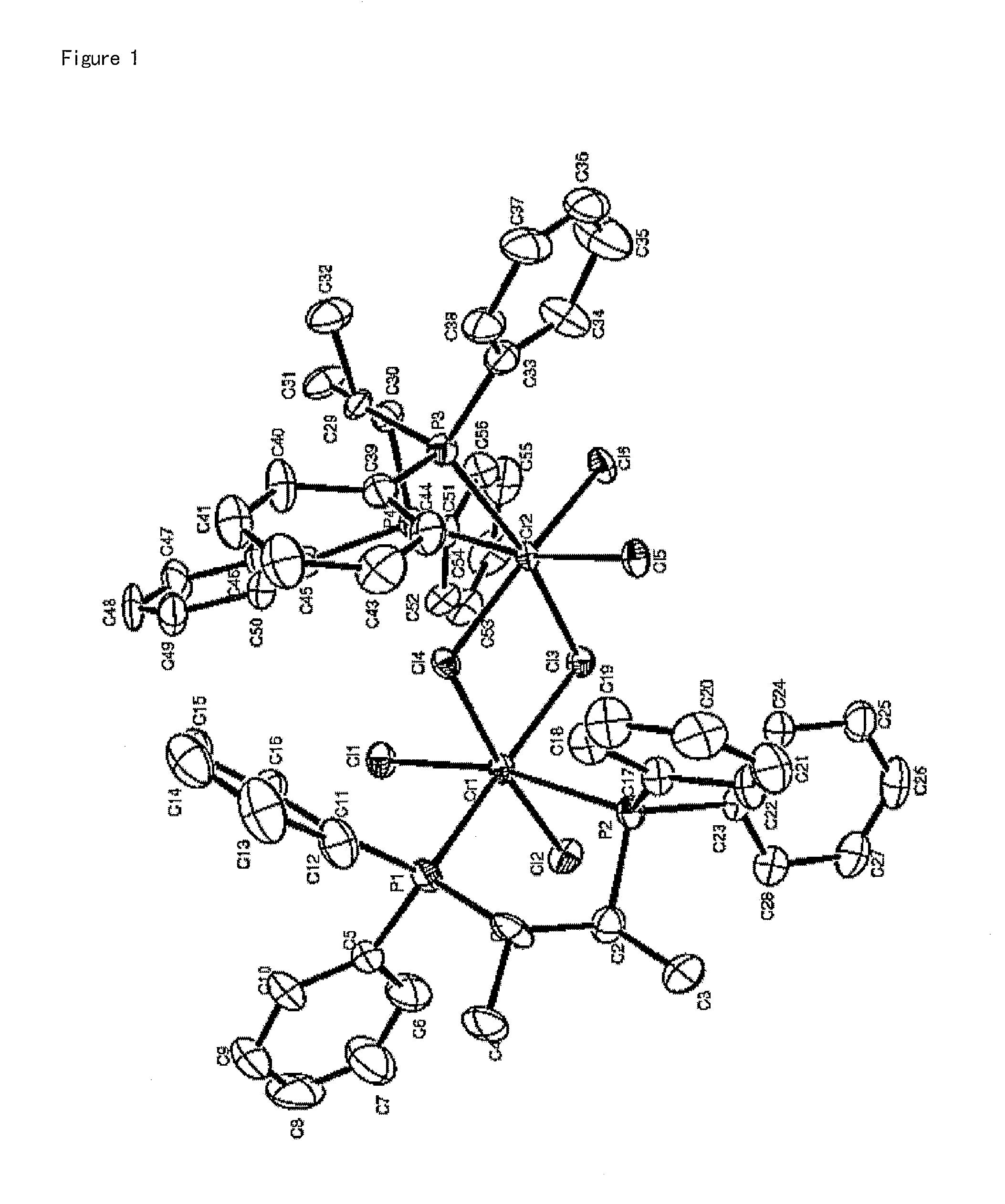

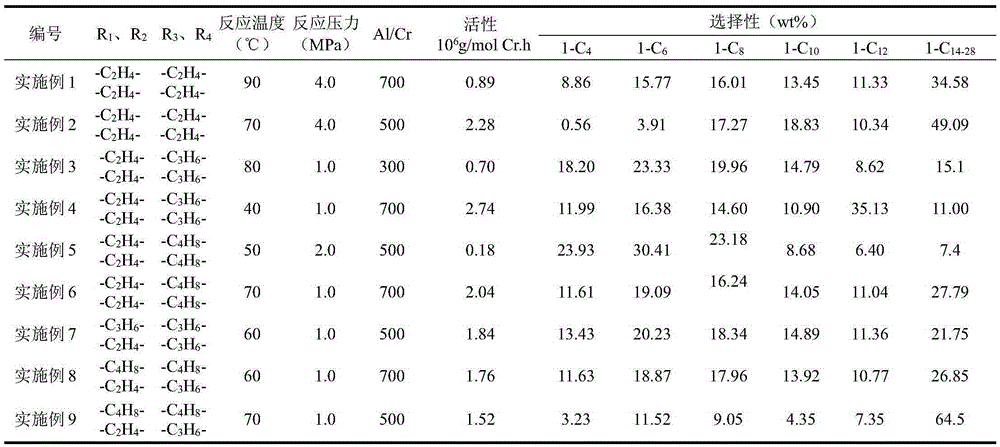

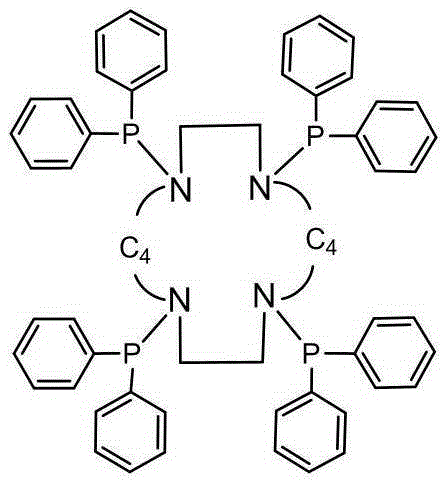

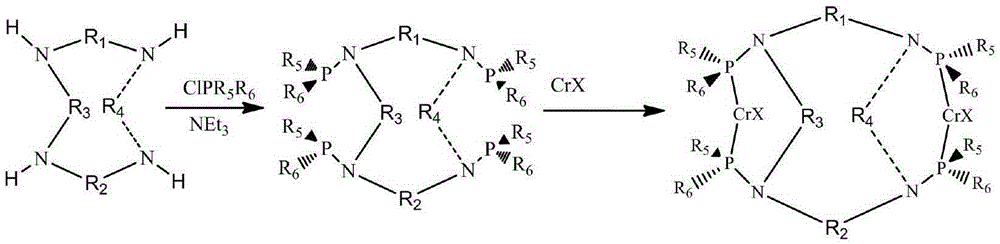

Dual-core chromium catalyst for ethylene oligomerization and preparation method thereof

ActiveCN105344381AHigh catalytic activityGood synergyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsDual coreAlpha-olefin

The invention relates to a dual-core chromium catalyst for ethylene oligomerization and a preparation method thereof; the dual-core chromium catalyst contains a transition metal chromium complex with a dual-core structure and an organic metal compound activator, the transition metal chromium complex with the dual-core structure is a compound having the general formula (I) defined in the specification, wherein R1, R2, R3 and R4 are connection groups and can be arbitrarily selected from alkyl, naphthenic group, aryl or heteroatomic groups containing O and S having a chain base structure with 1-6 atoms, R4, R5 and R6 are arbitrarily arene or alkane substituents, and CrX is CrCl2, CrCl3, Cr(acac)3, chromium 2-ethylhexanoate or Cr(CO)6. The catalyst has the catalytic activity of greater than 4.92*10<6> g polymerization product*mol<-1> Cr*h<-1>, and the selectivity of linear alpha-olefin in products is more than 98%. The catalyst composition has the characteristics of simple preparation method, high catalytic activity, and fewer C1-C4 alkanes and high-polymerized products in the products.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com