Method for manufacturing chromatic aqueous metallic paint

A water-based metallic paint and its manufacturing method technology, applied to the surface coating liquid device, coating, etc., can solve the problems of large pigment requirement, not bright color, not aging resistance, etc., and achieve long retention time and excellent weather resistance Performance and stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

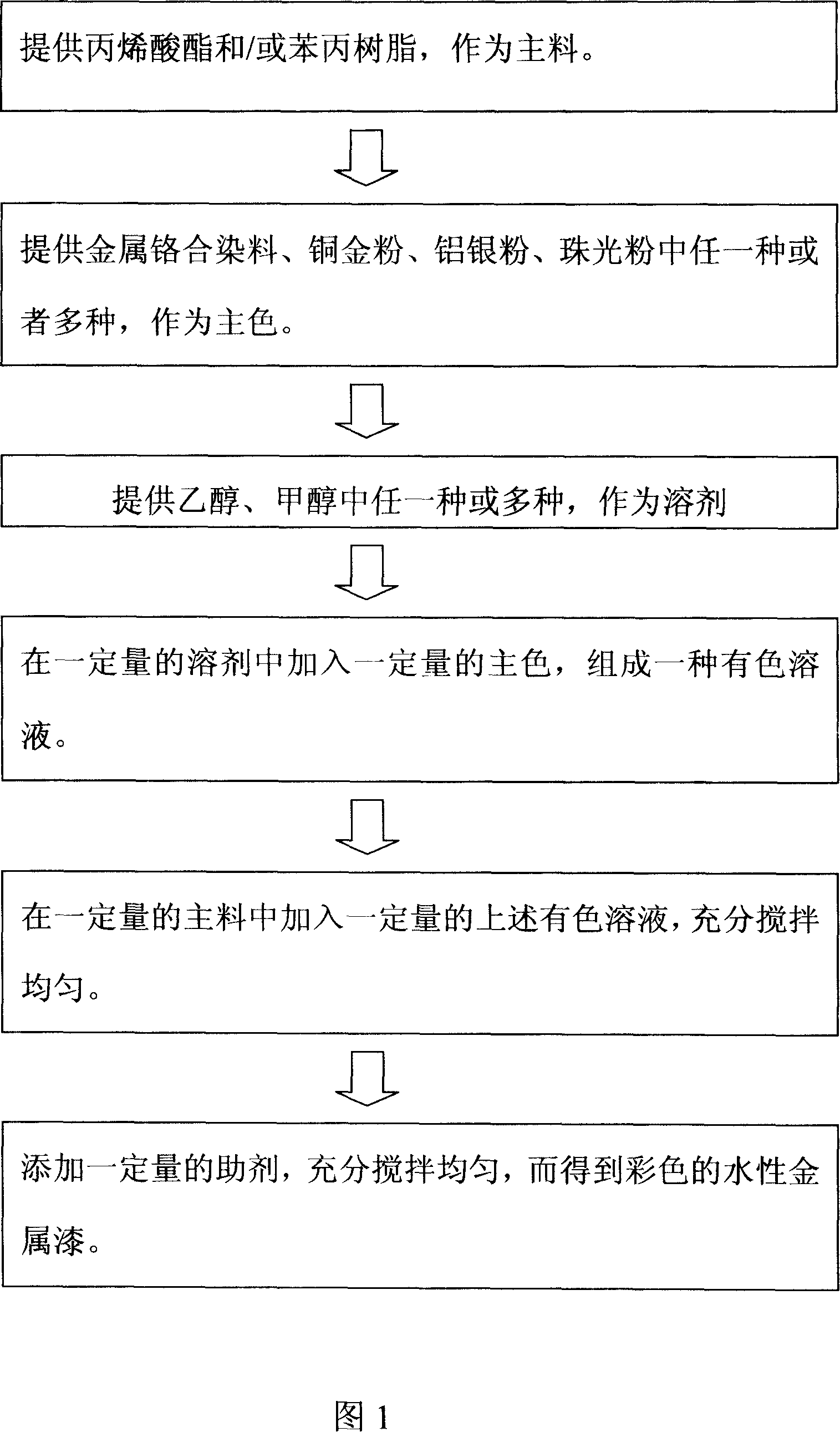

[0016] Please refer to Fig. 1, a kind of manufacture method of colored waterborne metallic paint, it may further comprise the steps:

[0017] Step 1: Provide acrylate and / or styrene-acrylic resin as the main material.

[0018] Step 2: Provide any one or more of metal chrome dyes, copper-gold powder, aluminum-silver powder, and pearl powder as the main color.

[0019] In metal complex dyes, metal ions form a complex with azo dyes in the form of coordination, which are widely used in acid dyes, leather dyes, solvent dyes, organic pigments and other fields.

[0020] Metallic chrome dyes are commercially available in a variety of different colors.

[0021] According to the needs, one metal chrome dye with a certain color can be selected, or a variety of metal chrome dyes with different colors can be mixed and used.

[0022] Step 3: Provide either ethanol or methanol as a solvent.

[0023] These organic solvents can better dissolve these metal chromium dyes, so that the color of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com