Insulating binder for coating amorphous and nanocrystalline magnetic powder and coating method

A binder and nanocrystalline technology, which is applied in the field of insulating binder and coating covering amorphous and nanocrystalline magnetic powder, can solve the problem of crystallization of amorphous and nanocrystalline magnetic powder, poor mechanical strength, and incomplete coating, etc. problems, to achieve excellent thermal stability and mechanical strength, improve overall performance, and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

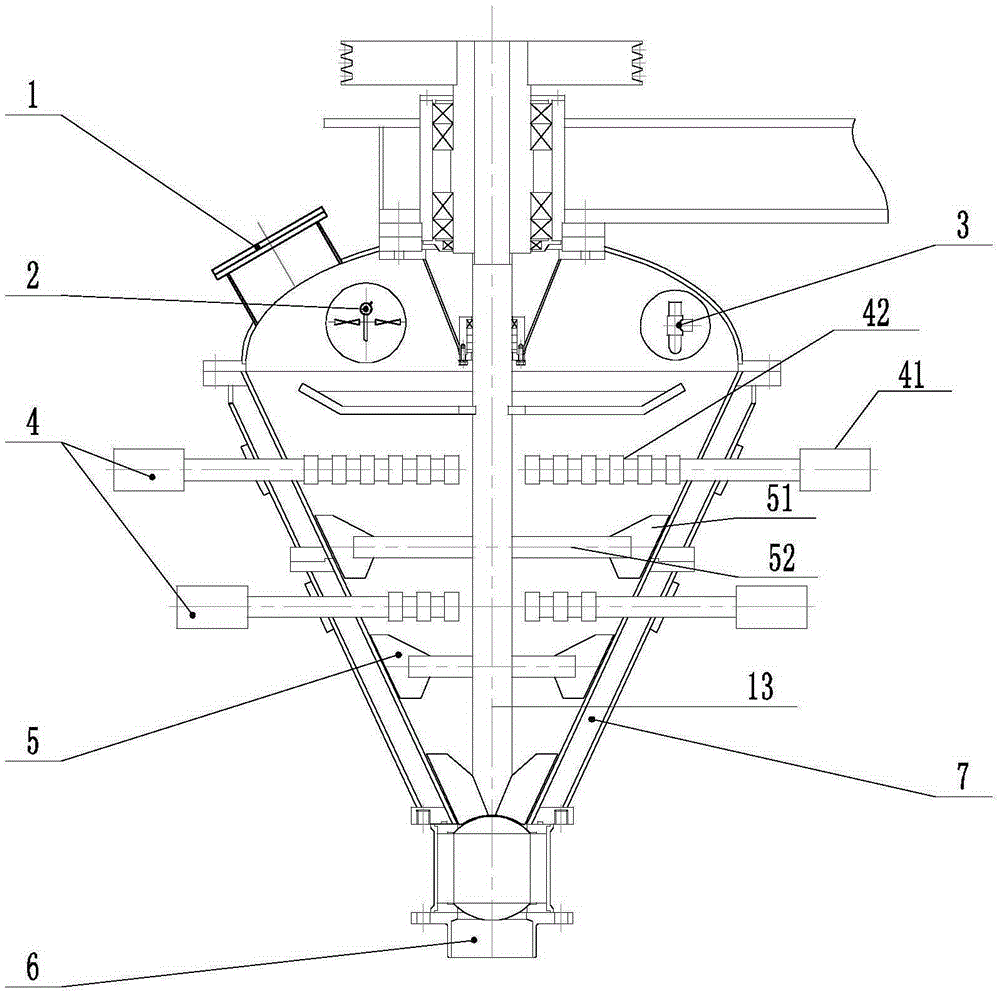

[0094] The coating pretreatment steps are as follows:

[0095] (1) First, add 5000g of magnetic powder into the housing 7 of the mixer through the feed port 1, and the magnetic powder is Fe 78 Si 9 B 13 Amorphous magnetic powder, the particle size is -100 mesh to +300 mesh.

[0096] (2) then, start mechanical stirring paddle 5, the stirring speed that mechanical stirring paddle 5 is set is 100RPM,

[0097] (3) After that, add the dehydrated ethanol solution of surface modification material (aminopropyltriethoxysilane KH550) in the housing 7 of stirrer again by inlet 1, wherein the consumption of surface modification material is magnetic powder weight 0.5%, the concentration of the surface modification material solution is 0.5wt%.

[0098] (4) Restart the ultrasonic vibrating rod 4, the stirring frequency of the ultrasonic vibrating rod 4 is 30kHz, the stirring time of the ultrasonic vibrating rod 4 and the mechanical stirring paddle 5 are set to be 100min, after the mechan...

Embodiment 2

[0118] In this embodiment, except that the following content is different from embodiment 1, other operation steps are the same as embodiment 1. In this embodiment, the organic binder is polyimide Kapton, and the consumption is the weight of the uncoated magnetic powder 1%; the inorganic binder is alumina, and the dosage is 1% of the weight of the uncoated magnetic powder; the surface modification material is isopropoxy distearic acid acyloxy aluminate DL-411, and the dosage is 0.5% by weight of magnetic powder.

[0119] The coated powder obtained in the present invention can work under the condition of -50°C to 150°C.

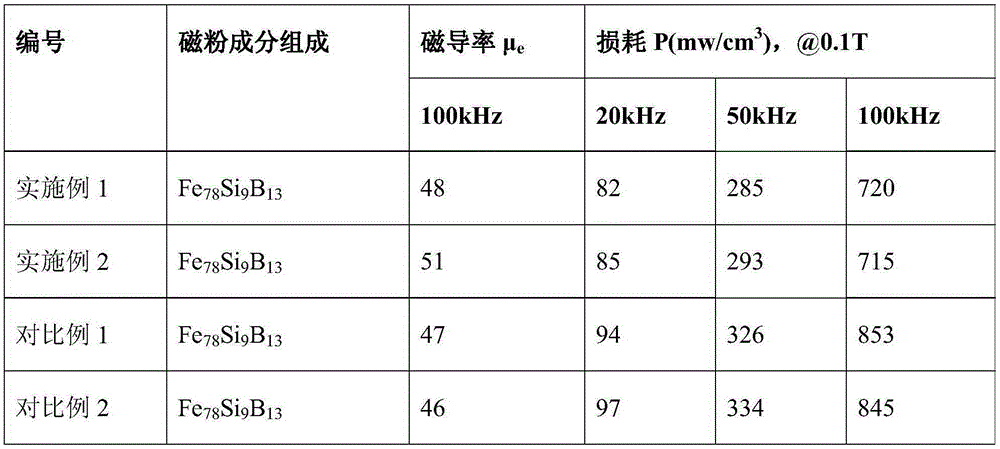

[0120] See Table 1 for the performance data of the magnetic powder core obtained in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com