Caliper type chromium complex and preparation method and application thereof

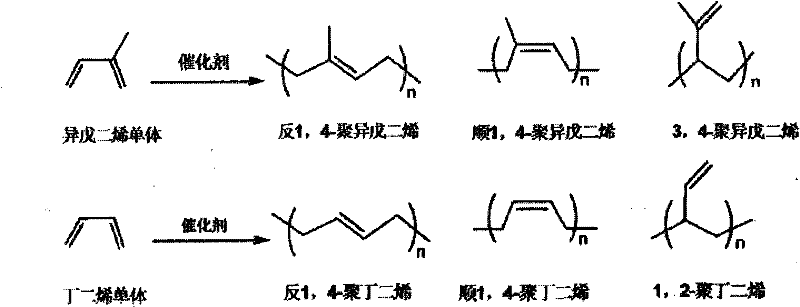

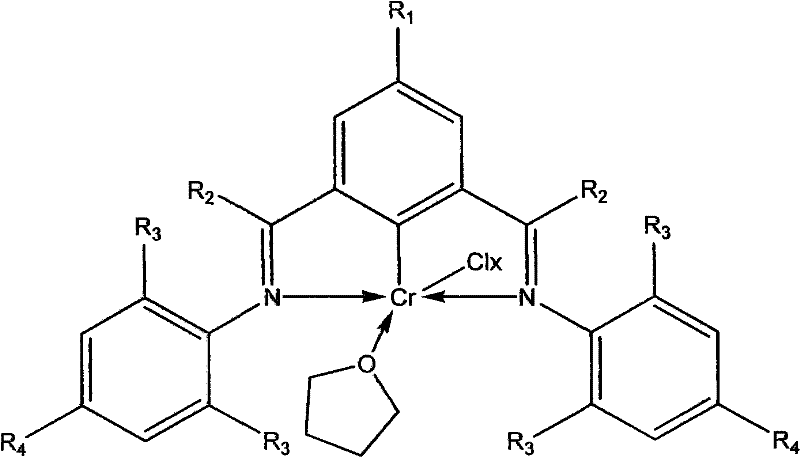

A chromium complex, pincer type technology, applied to catalysts containing pincer chromium complexes, catalyzing isoprene or butadiene trans-1 field, can solve the problems of different polymer ratios, difficulties, etc., and achieve a narrow molecular weight distribution. , the effect of fast polymerization reaction and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

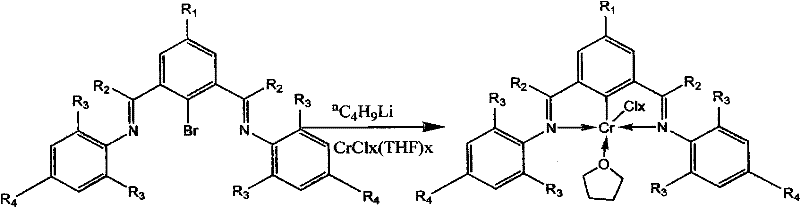

[0037] Example 1 Preparation of clamp-type chromium complex (chromium complex 1)

[0038]

[0039] At -78°C, a hexane solution of butyllithium (1.2mL, 1.88mmol) was slowly added dropwise to 2,6-bis(N-2,6-phenyl)iminobromobenzene (0.6690g , 1.84mmol) in 30mL tetrahydrofuran solution, add CrCl to it after 30 minutes of low temperature reaction 3 (THF) 3 (0.7043g, 1.88mmol), naturally warmed to room temperature and continued to react for 4 hours, the solvent was removed in vacuo, the residue was extracted with toluene, and the toluene solution was concentrated to obtain 0.52 g of bright green crystal complex 1 with a yield of 60%. Elemental analysis, its molecular formula is C 24 h 23 Cl 2 CrN 2 O (%): C, 60.26; H, 4.85; N 5.86.

Embodiment 2

[0040] Example 2 Preparation of clamp-type chromium complex (chromium complex 2)

[0041]

[0042] At -78°C, a hexane solution of butyllithium (0.86mL, 1.35mmol) was slowly added dropwise to 2,6-bis(N-2,6-dimethylphenyl)iminobromobenzene (0.5625g, 1.34mmol) in 30mL tetrahydrofuran solution, add CrCl to it after 30 minutes of low temperature reaction 3 (THF) 3 (0.5148g, 1.37mmol), naturally warmed to room temperature and continued to react for 4 hours, the solvent was removed in vacuo, the residue was extracted with toluene, and the toluene solution was concentrated to obtain 0.50 g of bright green crystal complex 2 with a yield of 71%. Elemental analysis, its molecular formula is C 28 h 31 Cl 2 CrN 2 O (%): C, 62.92; H, 5.85; N, 5.24.

Embodiment 3

[0043] Example 3 Preparation of clamp-type chromium complex (chromium complex 3)

[0044]

[0045] At -40°C, a hexane solution of butyl lithium (1.33 mL, 1.33 mmol) was slowly added dropwise to 2,6-bis(N-2,6-diethylphenyl)iminobromobenzene (0.5773g, 1.21mmol) in 30mL tetrahydrofuran solution, add CrCl to it after 30 minutes of low temperature reaction 3 (THF) 3 (0.5100g, 1.36mmol), naturally warmed to room temperature and continued to react for 4 hours, the solvent was removed in vacuo, the residue was extracted with toluene, and the toluene solution was concentrated to obtain 0.42 g of bright green crystal complex 3 with a yield of 56%. Elemental analysis, its molecular formula is C 32 h 39 Cl 2 CrN 2 O (%): C, 65.08; H, 6.66; N, 4.74.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com