Photosensitive silver paste and touch screen and electronic apparatus employing photosensitive silver paste

A technology of touch screen and silver paste, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of small adhesion and easy falling off, and achieve the effects of improving adhesion, reducing defects and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

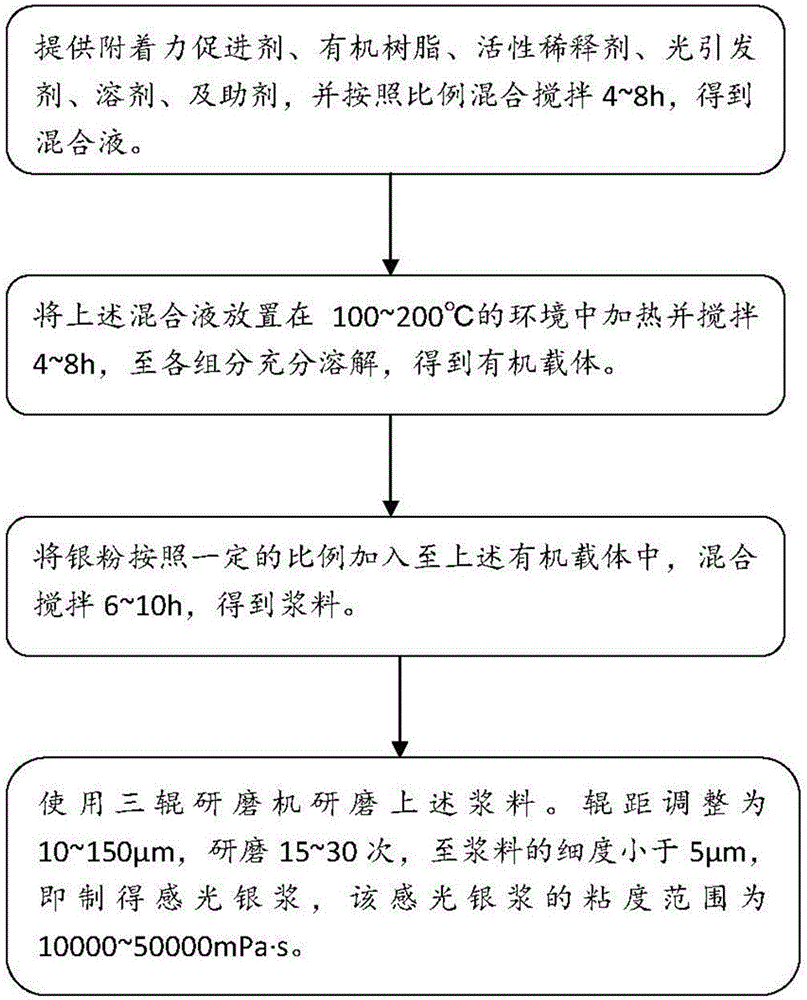

[0027] see figure 1 , the preparation method of described photosensitive silver paste, it comprises the steps:

[0028] Provide adhesion promoter, organic resin, reactive diluent, photoinitiator, solvent, and additives, and mix and stir for 4-8 hours according to the proportion to obtain a mixed solution.

[0029] The above mixed solution is placed in an environment of 100-200° C., heated and stirred for 4-8 hours until all components are fully dissolved to obtain an organic vehicle.

[0030] Add the silver powder to the above organic carrier according to a certain proportion, mix and stir for 6-10 hours to obtain a slurry.

[0031] The above slurry was ground using a three-roll mill. Adjust the roll distance to 10-150 μm, grind for 15-30 times until the fineness of the slurry is less than 5 μm, then the photosensitive silver paste is prepared, and the viscosity range of the photosensitive silver paste is 10000-50000mPa·s.

Embodiment 1

[0034] In this embodiment, the photosensitive silver paste is prepared from an organic vehicle and silver powder, wherein the mass fraction of the organic vehicle is 30%, and the mass fraction of the silver powder is 70%.

[0035] The organic carrier consists of titanate coupling agent, aromatic epoxy resin, epoxy modified acrylic resin, α-methacrylic acid, 1-hydroxycyclohexyl phenyl ketone, diethylene glycol monoethyl ether acetate, Prepared from TEGO Airex 931 (Tego additive), dioctyl phthalate, TEGO Flow 425 (Tego additive) and fumed silica. In this organic vehicle, the mass fraction of titanate coupling agent is 7%, the mass fraction of aromatic epoxy resin is 30%, the mass fraction of epoxy-modified acrylic resin is 14.5%, the mass fraction of α-methacrylic acid The fraction is 15%, the mass fraction of 1-hydroxycyclohexyl phenyl ketone is 8%, the mass fraction of diethylene glycol monoethyl ether acetate is 20%, and the mass fraction of TEGO Airex 931 (Digo additive) is ...

Embodiment 2

[0037] In this embodiment, the photosensitive silver paste is prepared from an organic vehicle and silver powder, wherein the mass fraction of the organic vehicle is 30%, and the mass fraction of the silver powder is 70%.

[0038]The organic vehicle is composed of acrylate phosphate, aromatic epoxy resin, epoxy modified acrylic resin, α-methacrylic acid, 1-hydroxycyclohexyl phenyl ketone, diethylene glycol monoethyl ether acetate, TEGO Airex 931 (Tego additive), dioctyl phthalate, TEGO Flow 425 (Tego additive) and fumed silica. In the organic vehicle, the mass fraction of phosphate acrylate is 7%, the mass fraction of aromatic epoxy resin is 30%, the mass fraction of epoxy-modified acrylic resin is 14.5%, and the mass fraction of α-methacrylic acid is 15%. %, the mass fraction of 1-hydroxycyclohexyl phenyl ketone is 8%, the mass fraction of diethylene glycol monoethyl ether acetate is 20%, the mass fraction of TEGO Airex 931 (Digo additive) is 2%, and the o The mass fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com