Organic silicon modified phenolic resin encapsulating material and preparation method and usage thereof

A phenolic resin, silicone technology, applied in resistor casing/packaging/potting, fixed capacitor casing/packaging, resistors with positive temperature coefficient, etc., can solve the problem of poor pressure resistance, high manufacturing cost, mechanical strength low problems, to achieve the effect of significant economic benefits, low manufacturing costs, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

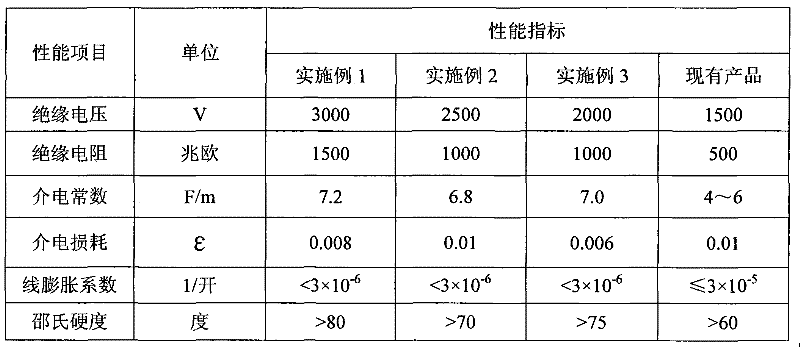

Examples

Embodiment 1

[0036] Formula 1: The silicone-modified phenolic resin encapsulant is composed of the following raw materials in parts by weight: 17 parts of modified phenolic resin, 5 parts of titanium dioxide, 1 part of silicone, 60 parts of silicon micropowder, 5 parts of pigment, thixotropic 3 parts of desiccant, 5 parts of desiccant, 4 parts of curing agent. Among them: Except for the modified phenolic resin which is a specially developed new product, the rest of the raw materials are all existing products. The microsilica powder is a 320-mesh granular shape, and its main component is SiO 2 ≥99%, Fe 2 o 3 <3‰; the organosilicon is liquid organosilicon 560.

[0037] Use the preparation method of the organosilicon-modified phenolic resin encapsulant of formula 1, and its process step is as follows:

[0038] (1) Spray treatment: In the Φ600 vertical mixer, the diluted liquid silicone is evenly sprayed in the granular silicon micropowder in the form of a mist by an air pump, covering eac...

Embodiment 2

[0043]Formula 2: The organosilicon-modified phenolic resin encapsulant consists of the following raw materials in parts by weight: 15 parts of modified phenolic resin, 4 parts of titanium dioxide, 2 parts of silicone, 62 parts of silicon micropowder, 5 parts of pigment, thixotropic 3 parts of desiccant, 5 parts of desiccant, 4 parts of curing agent.

[0044] The steps of the method for preparing the silicone-modified phenolic resin encapsulant using Formula 2 are the same as those in Example 1.

Embodiment 3

[0046] Formula 3: The organosilicon modified phenolic resin encapsulant is composed of the following raw materials in parts by weight: 19 parts of modified phenolic resin, 5 parts of titanium dioxide, 1 part of silicone, 55 parts of silicon micropowder, 5 parts of pigment, thixotropic 3 parts of desiccant, 5 parts of desiccant, 7 parts of curing agent.

[0047] The steps of the method for preparing the silicone-modified phenolic resin encapsulant using Formula 3 are the same as those in Example 1.

[0048] The organosilicon modified phenolic resin encapsulating material of the invention is mainly used in encapsulating ceramic dielectric capacitors, ceramic filters and thermistors.

[0049] The organosilicon-modified phenolic resin encapsulant prepared by the present invention is in the form of dry powder. When used specifically, it needs to be mixed with a mixed solvent at a weight ratio of 100:25 to form an organosilicon for impregnating and encapsulating electronic component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com