Low-VOC automobile varnish and preparation method thereof

A technology for automobiles and varnishes, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of large VOC emissions, high cost, and complex formulations, and achieve good film fullness, improved adhesion, and solid content in construction high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

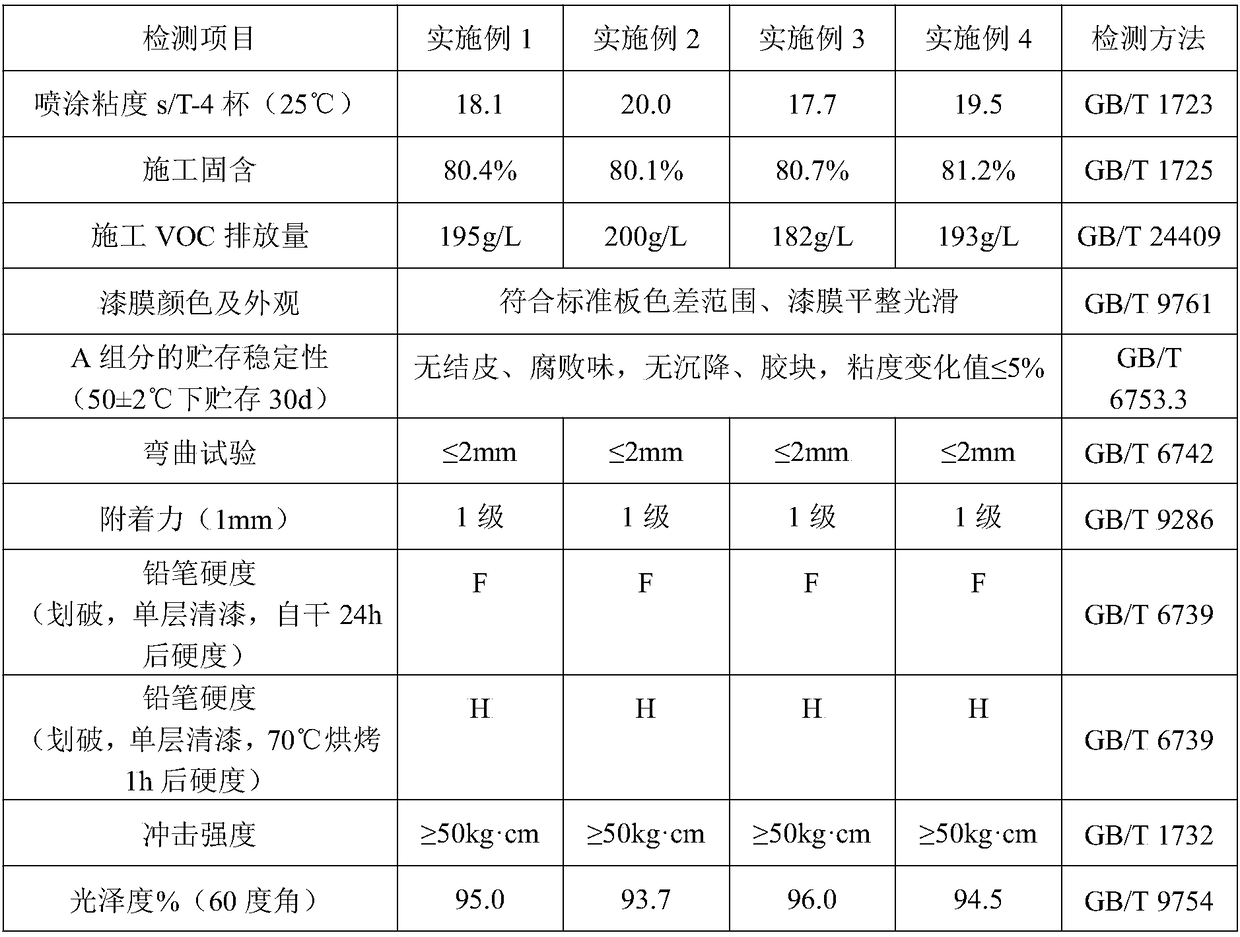

[0032] Embodiment 1~4, low VOC automobile varnish of the present invention and preparation thereof

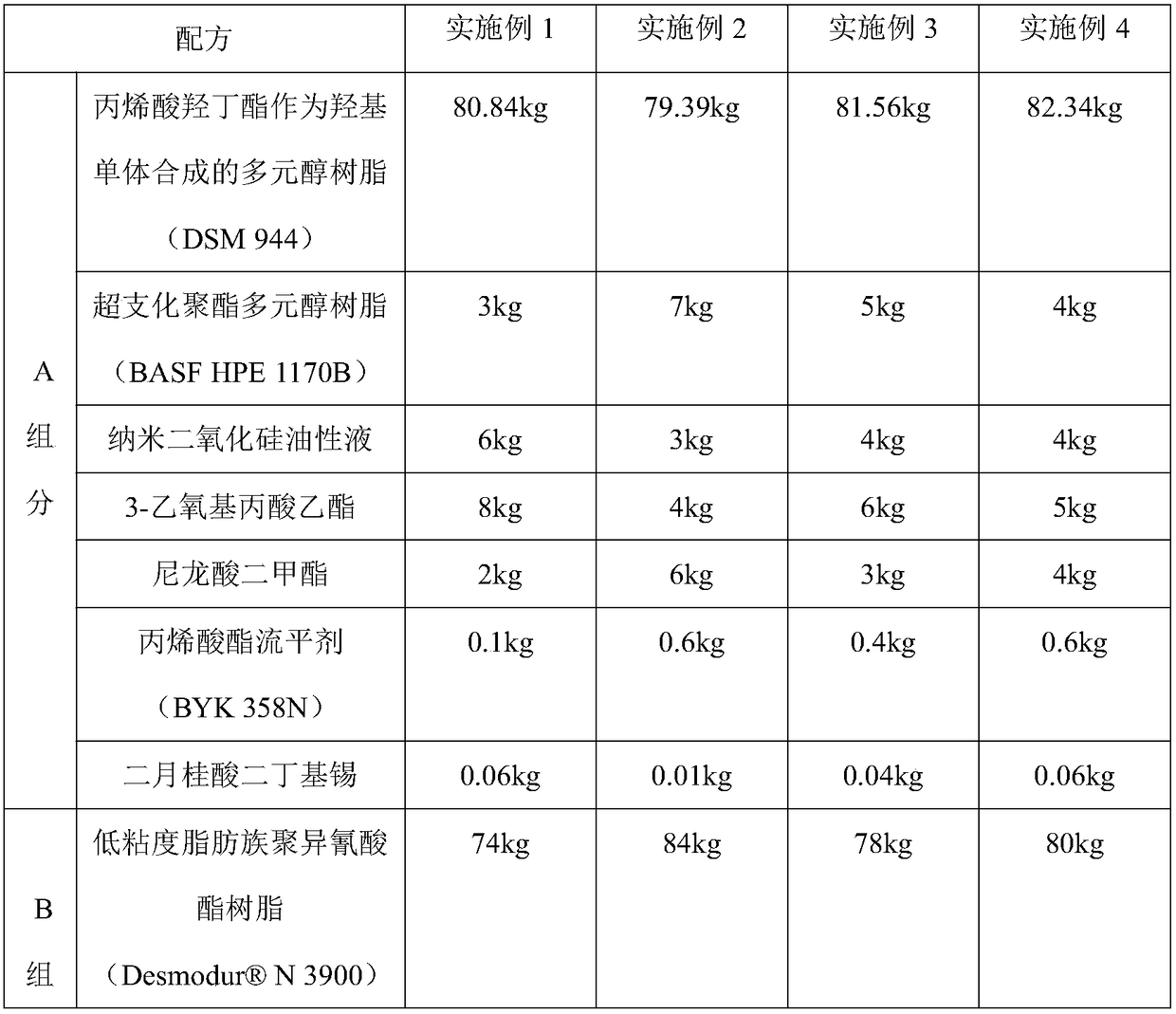

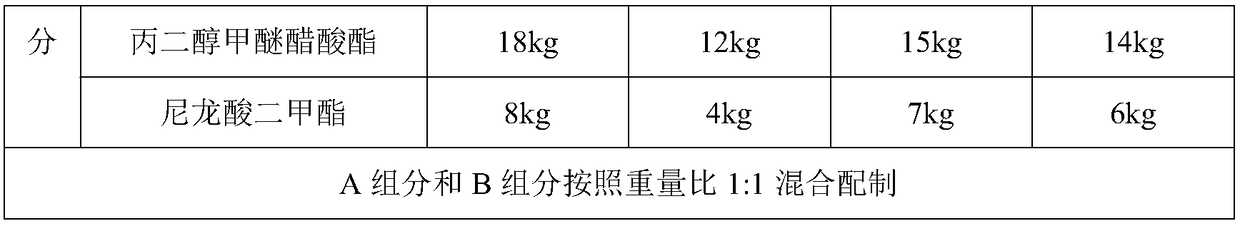

[0033] As shown in Table 1 below, the weight ratio tables of 4 examples of low-VOC automotive varnishes of the present invention are listed.

[0034] Table 1

[0035]

[0036]

[0037] Preparation:

[0038]S1. Preparation of component A: According to the formula amount, put polyol resin and hyperbranched polyester polyol resin synthesized by hydroxybutyl acrylate as hydroxyl monomer into the mixing tank, put nano silicon dioxide oily liquid under stirring, stir After 10 minutes, add 3-ethoxy ethyl propionate, dimethyl nylon acid, acrylate leveling agent and dibutyltin dilaurate, and stir for another 10 minutes to obtain component A;

[0039] S2. Preparation of component B: according to the formula, put propylene glycol methyl ether acetate and dimethyl nylon acid into the mixing tank, then flush into nitrogen, put in low-viscosity aliphatic polyisocyanate resin under st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com