Powder paint and production method and application thereof

A technology of powder coatings and raw materials, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems affecting the promotion and application of HAA-curable powder coatings, eye irritation and allergy, animal cell mutagenesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

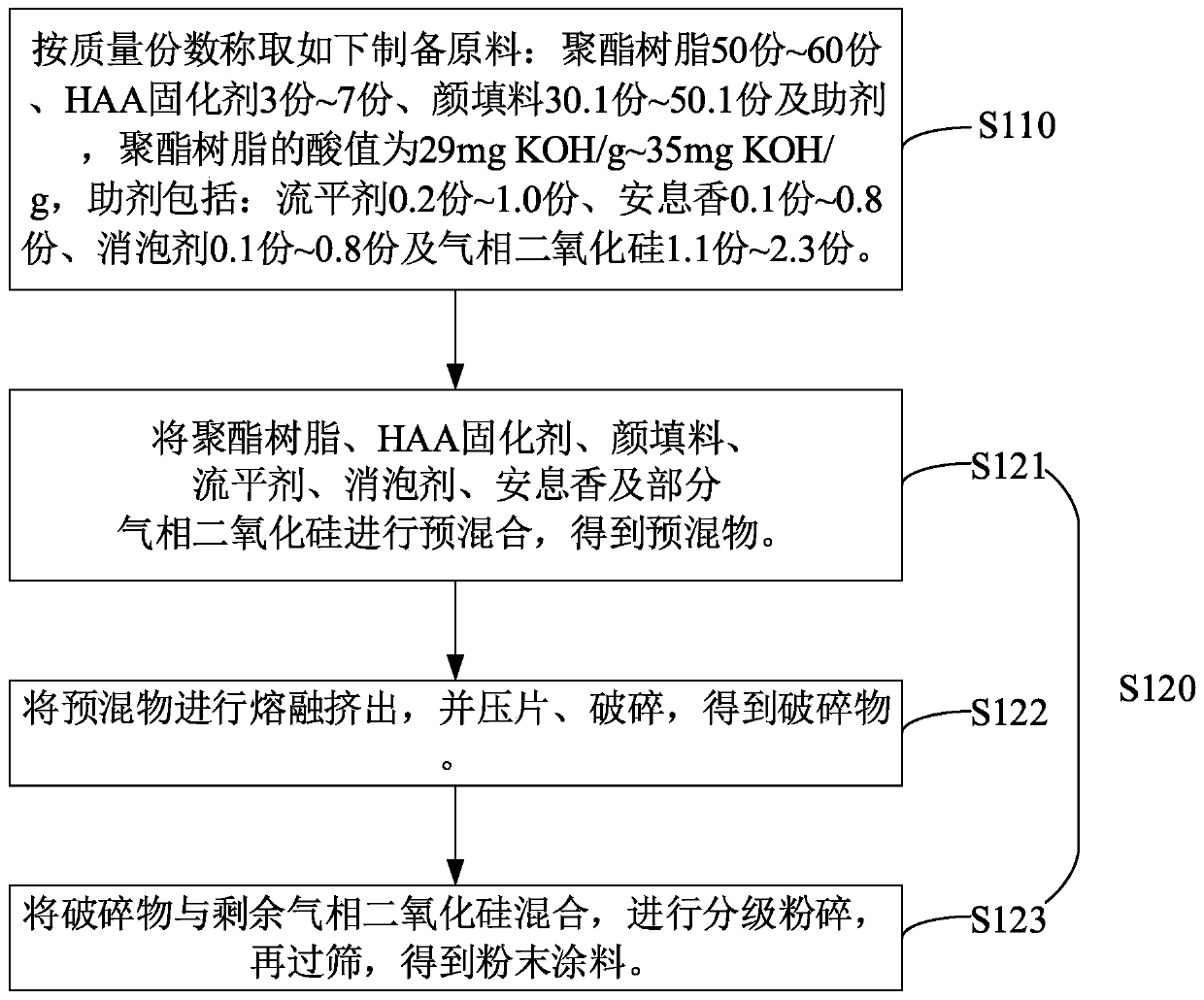

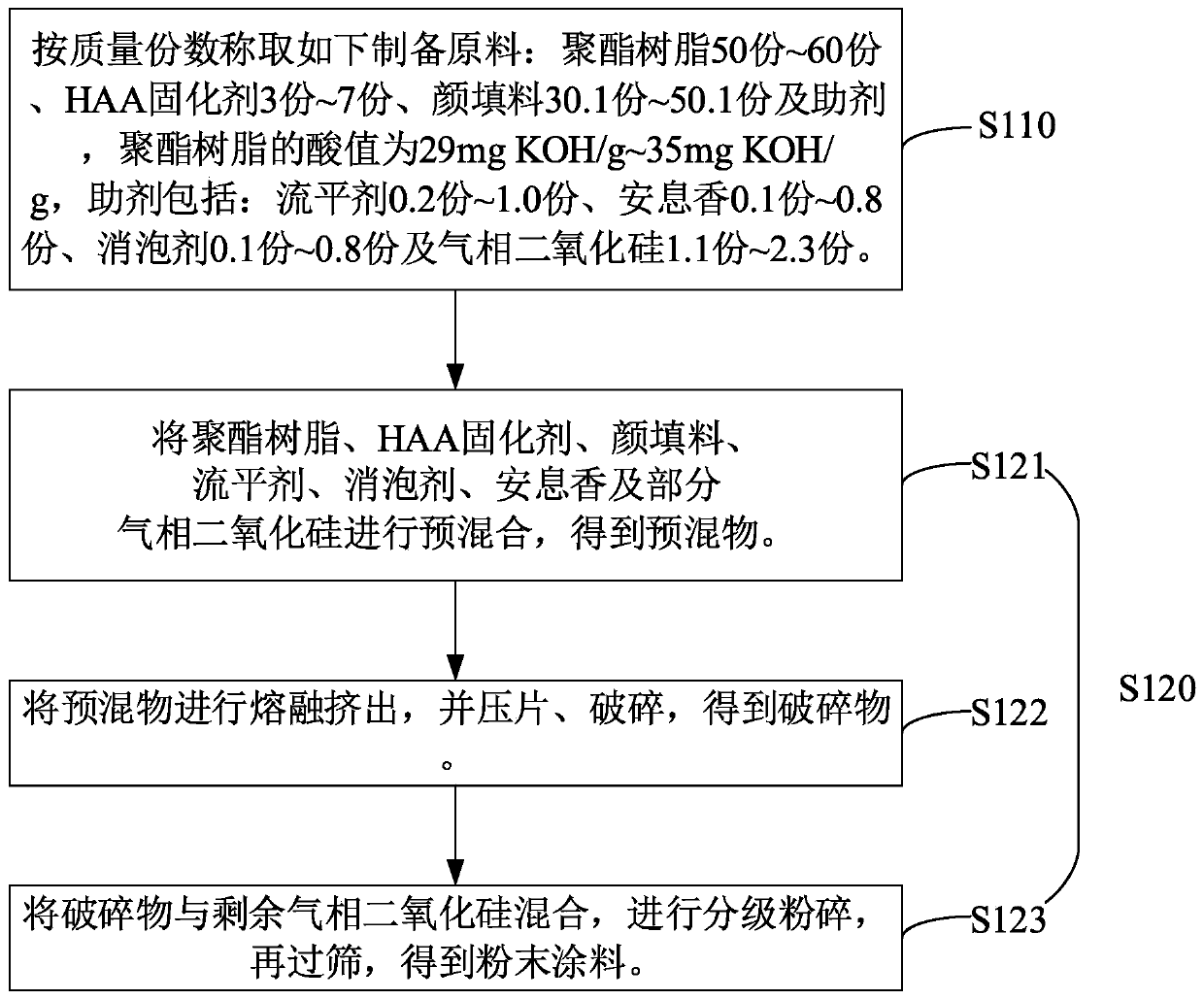

[0044] see figure 1 , the preparation method of the powder coating of an embodiment, comprises the following steps:

[0045] Step S110: Weigh raw materials according to the following parts by mass: 50-60 parts of polyester resin, 3-7 parts of HAA curing agent, 30.1-50.1 parts of pigments and fillers and additives, the acid value of polyester resin is 29 mg KOH / g~35mg KOH / g, additives include: 0.2-1.0 parts of leveling agent, 0.1-0.8 parts of benzoin, 0.1-0.8 parts of defoamer and 1.1-2.3 parts of fumed silica.

[0046] Among them, the softening point of the polyester resin is 100°C to 110°C. The viscosity of polyester resin is 4500mpa.s~5500mpa.s (200°C). The HAA curing agent is N, N, N', N'-tetra(β-hydroxypropyl) adipamide. The hydroxyl equivalent of the HAA curing agent is 90g / eq-100g / eq.

[0047] Pigments and fillers include pigments and fillers. Specifically, in parts by mass, the pigment includes 10-16 parts of titanium dioxide. Fillers include barium sulfate and q...

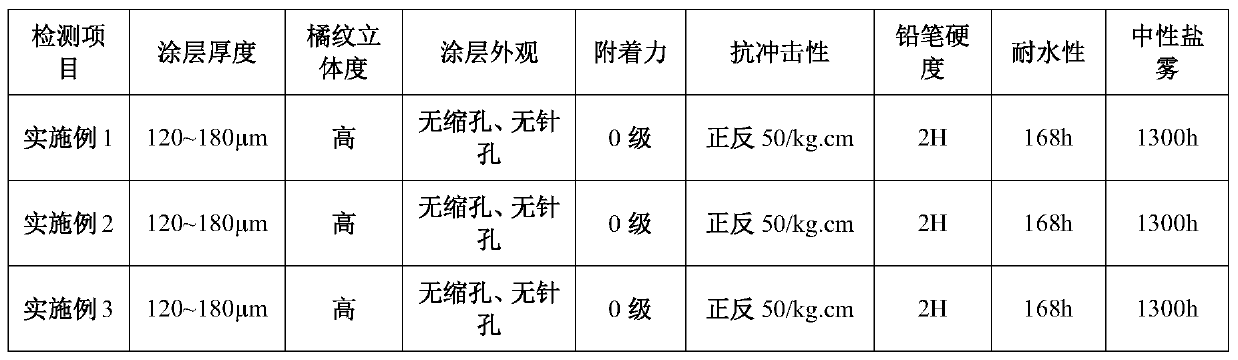

Embodiment 1

[0071] The preparation process of the powder coating of the present embodiment is as follows:

[0072] (1) In parts by mass, weigh the following raw materials: 50 parts of polyester resin, 3 parts of HAA curing agent, 10 parts of titanium dioxide, 12 parts of barium sulfate, 8 parts of quartz powder, 0.2 parts of leveling agent, defoamer 0.1 part, 0.1 part of benzoin, 0.1 part of 2-methylimidazole, 1.2 parts of fumed silica, 0.06 part of carbon black, 0.02 part of phthalocyanine green, 0.02 part of phthalocyanine blue and 0.2 part of embossing agent. Among them, the acid value of the polyester resin is 29 mg KOH / g to 35 mg KOH / g. The softening point is 100°C. The viscosity is 5000mpa.s (200°C). The hydroxyl equivalent of the HAA curing agent is 100g / eq. The leveling agent is PV88 from Dexinli Chemical Company. The defoamer is YPZ from Hubei Laisi Chemical New Material Co., Ltd.

[0073] (2) Mix 50 parts of polyester resin, 3 parts of HAA curing agent, 10 parts of titanium...

Embodiment 2

[0078] The preparation process of the powder coating of the present embodiment is as follows:

[0079] (1) In parts by mass, weigh the following raw materials: 55 parts of polyester resin, 5 parts of HAA curing agent, 13 parts of titanium dioxide, 16 parts of barium sulfate, 11 parts of quartz powder, 0.6 parts of leveling agent, defoamer 0.5 parts, 0.5 parts of benzoin, 0.2 parts of 2-methylimidazole, 1.7 parts of fumed silica, 0.06 parts of carbon black, 0.02 parts of phthalocyanine green, 0.02 parts of phthalocyanine blue and 0.3 parts of embossing agent. Among them, the acid value of the polyester resin is 29 mg KOH / g to 35 mg KOH / g. The softening point is 110°C. The viscosity is 5500mpa.s (200°C). The hydroxyl equivalent of the HAA curing agent is 95g / eq. The leveling agent is P67 from Dexinli Chemical Company. The defoamer is F-2572 from Guangdong Tianfeng Defoamer Co., Ltd.

[0080] (2) 55 parts of polyester resin, 5 parts of HAA curing agent, 13 parts of titanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com