Aluminum alloy for semiconductor equipment and preparation method thereof

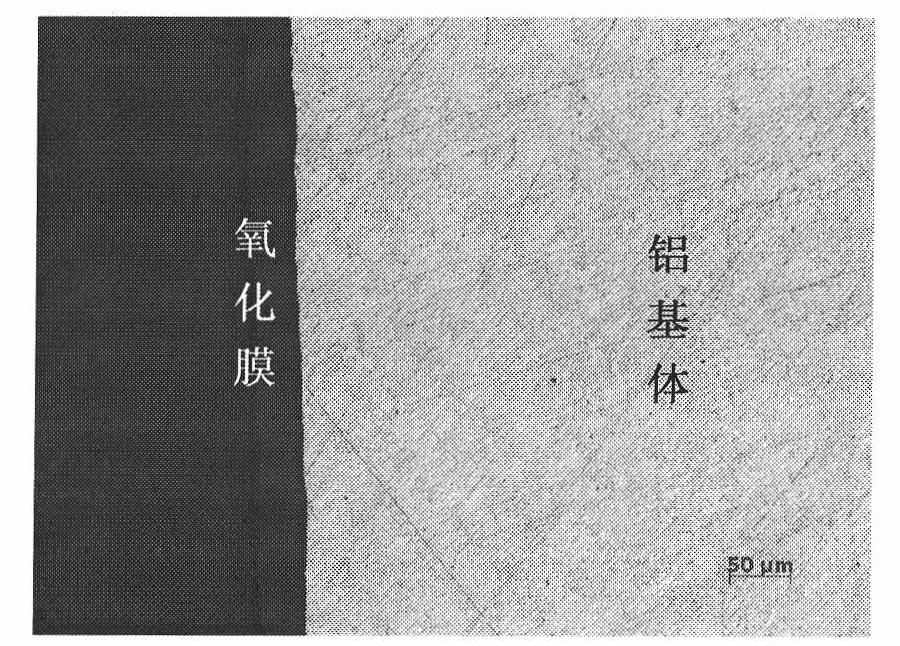

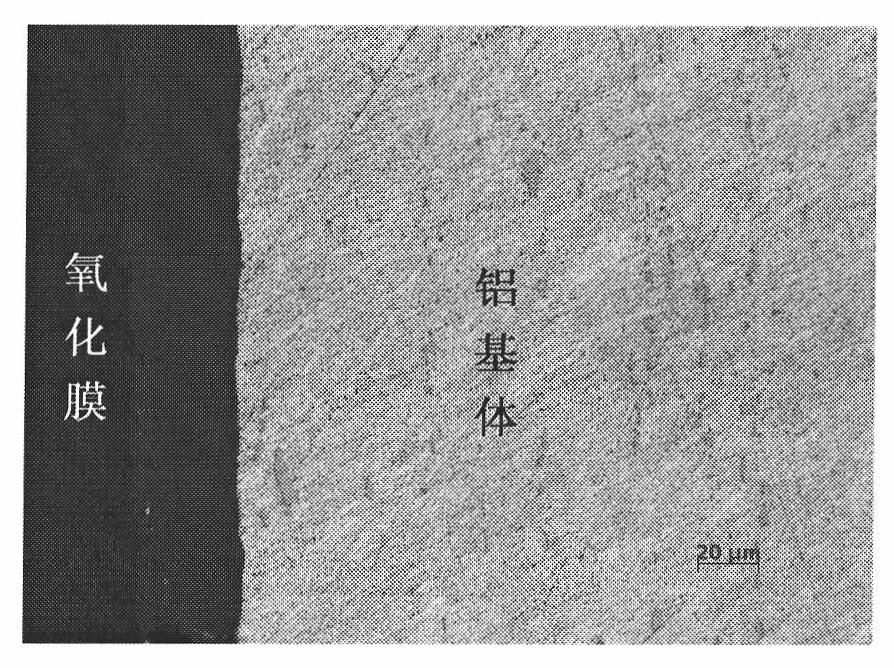

A technology of aluminum alloy and semiconductor, which is applied in the field of non-ferrous metal processing, aluminum alloy for semiconductor equipment and its preparation. It can solve the problems of poor product stability and quality control that cannot meet the needs of semiconductors, and achieve uniform oxide film, improved structure, and uniform structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The alloy composition of the present invention is controlled as: Mg 1.20%, Si 0.75%, Cu 0.15%, Cr 0.20%, Mn 0.40%, Ti 0.02%, Fe 0.3%, the total of other impurity elements: 0.01%, Al: balance, Mg / Si 1.6, electromagnetic casting is 400×400×150mm ingot. After being qualified, it is transferred to forging and processed into aluminum alloy ingots for semiconductor equipment.

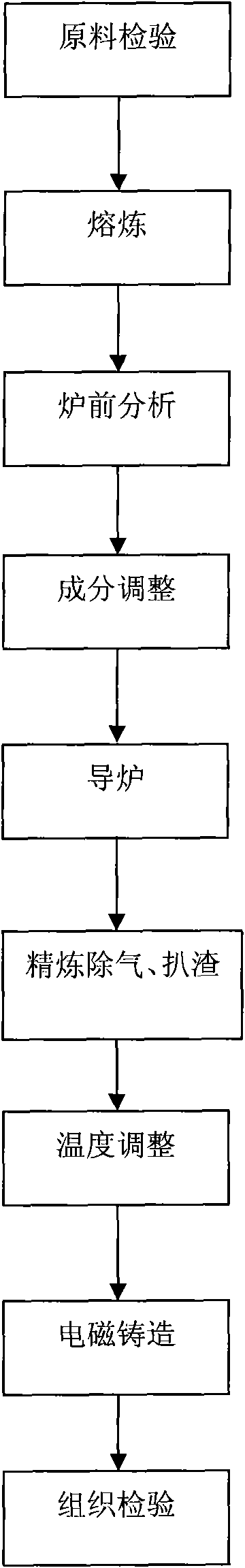

[0044] Such as figure 1 Shown, is process flow diagram of the present invention. The specific steps are as follows:

[0045] (1) Raw material inspection: inspect the raw materials, requiring no oil pollution, entrainment, etc.;

[0046] (2) Smelting: first, 2KgAl-Ti master alloy (Al is 96%, Ti is 4%), 15KgAl-Si master alloy (Al is 80%, Si is 20%) and 374.17Kg of pure metal Al (Al is 4%) 99.8%) into a smelting furnace for smelting under atmospheric conditions. After the alloy is melted, add 0.6Kg electrolytic Cu (99.8% Cu) at 680°C, and add 1.14Kg Cr agent at 750°C (Cr is 70wt%, the balance flux a...

Embodiment 2

[0055] The alloy composition of the present invention is controlled as: Mg 1.00%, Si 0.58%, Cu 0.10%, Cr 0.04%, Mn 0.10%, Ti 0.015%, Fe 0.3%, other impurity elements total: 0.01%, Al: balance, Mg / Si 1.73, electromagnetic casting is an ingot of 390×390×140mm. After being qualified, it is transferred to forging and processed into aluminum alloy ingots for semiconductor equipment.

[0056] (1) Raw material inspection: inspect the raw materials, requiring no oil pollution, entrainment, etc.;

[0057] (2) Smelting: first, 1.5KgAl-Ti master alloy (Al is 95%, Ti is 5%), 9.67KgAl-Si master alloy (Al is 70%, Si is 30%) and 482.455Kg pure metal Al is loaded The smelting furnace is smelted under atmospheric conditions. After the alloy is melted, 0.5Kg electrolytic Cu (99.9% of Cu) is added at 680°C, and 0.25Kg of Cr agent is added at 750°C (Cr is 80wt%, and the balance is flux and aluminum) and 0.625Kg Mn agent (Mn is 80wt%, the balance is flux and aluminum), and finally add 5Kg metal...

Embodiment 3

[0066] The alloy composition of the present invention is controlled as: Mg 1.15%, Si 0.65%, Mg / Si 1.7, Cu 0.12%, Cr 0.10%, Mn 0.25%, Ti 0.017%, Fe 0.01%, balance Al, electromagnetic casting is 390× 390×140mm ingot. After being qualified, it is transferred to forging and processed into aluminum alloy ingots for semiconductor equipment.

[0067] (1) Raw material inspection: inspect the raw materials, requiring no oil pollution, entrainment, etc.;

[0068] (2) Smelting: first, 3.4Kg Al-Ti master alloy (Al is 97%, Ti is 3%), 15.6Kg Al-Si master alloy (Al is 75%, Si is 25%) and 570.38Kg pure metal Al Put it into the smelting furnace for smelting under atmospheric conditions. After the alloy is melted, add 0.72Kg electrolytic Cu at 680°C, add 1Kg Cr agent (Cr is 60wt%, the balance is flux and aluminum) and 2KgMn agent (Mn is 60wt%, the balance is flux and aluminum), and finally add 6.9Kg metal Mg. The raw materials are stirred after softening and collapsing, and the surface is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com