Low-temperature ceramic package process method of diode

A technology of low-temperature ceramics and packaging technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and circuits. Improve heat dissipation and high temperature resistance, reduce void rate, and achieve good thermal matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

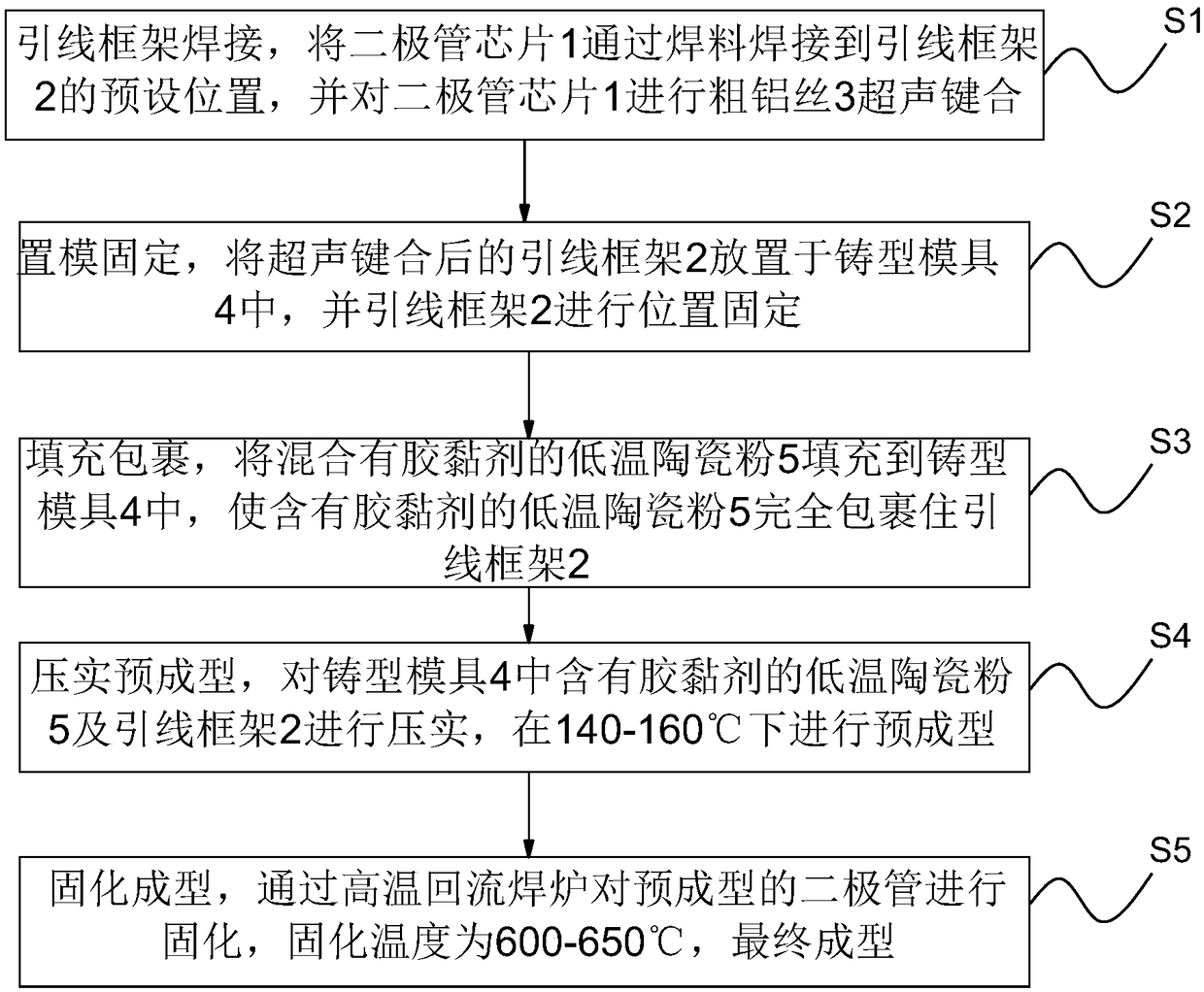

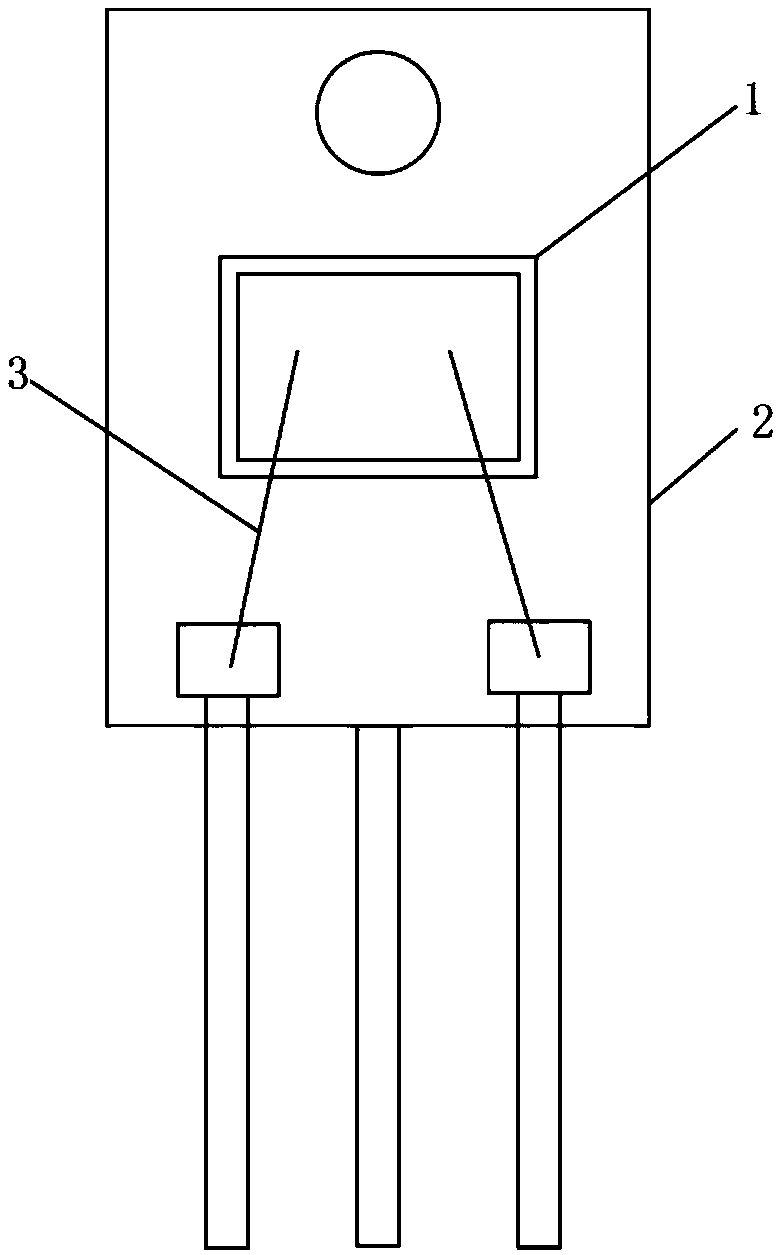

[0034] 1) Weld the Schottky diode chip 1 to the design position of the TO-264 lead frame 2DIE through high-temperature solder, and perform ultrasonic bonding on the diode chip 1 with thick aluminum wire 3, see figure 2 ;

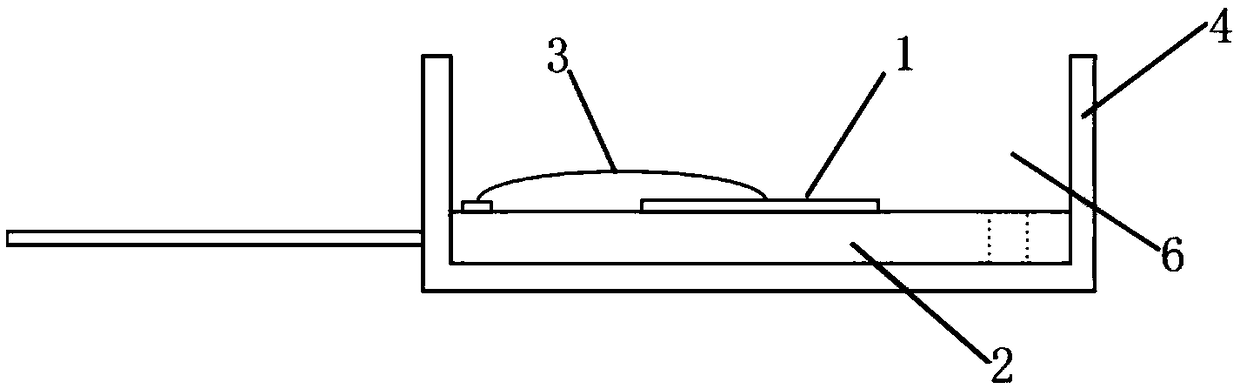

[0035] 2) Place the ultrasonically bonded lead frame 2 in the casting mold 4, and fix the position of the lead frame 2, see image 3 ;

[0036] 3) Fill the low-temperature ceramic powder 5 mixed with the adhesive into the casting mold 4, so that the low-temperature ceramic powder 5 containing the adhesive completely wraps the lead frame 2, see Figure 4 ;

[0037] 4) compacting the low-temperature ceramic powder 5 containing adhesive in the casting mold 4 and the lead frame 2, and preforming at 150° C.;

[0038] 5) The preformed diode is cured in a high-temperature reflow oven at a curing temperature of 600-650° C. for final molding.

[0039] Adopting the low-temperature ceramic powder forming and curing process of the present invention, since the ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com