Patents

Literature

31results about How to "Moderate melting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brazing filler metal for brazing W-Cu composite and Fe-based alloy, method and brazing technique

ActiveCN105081597AModerate melting temperatureFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

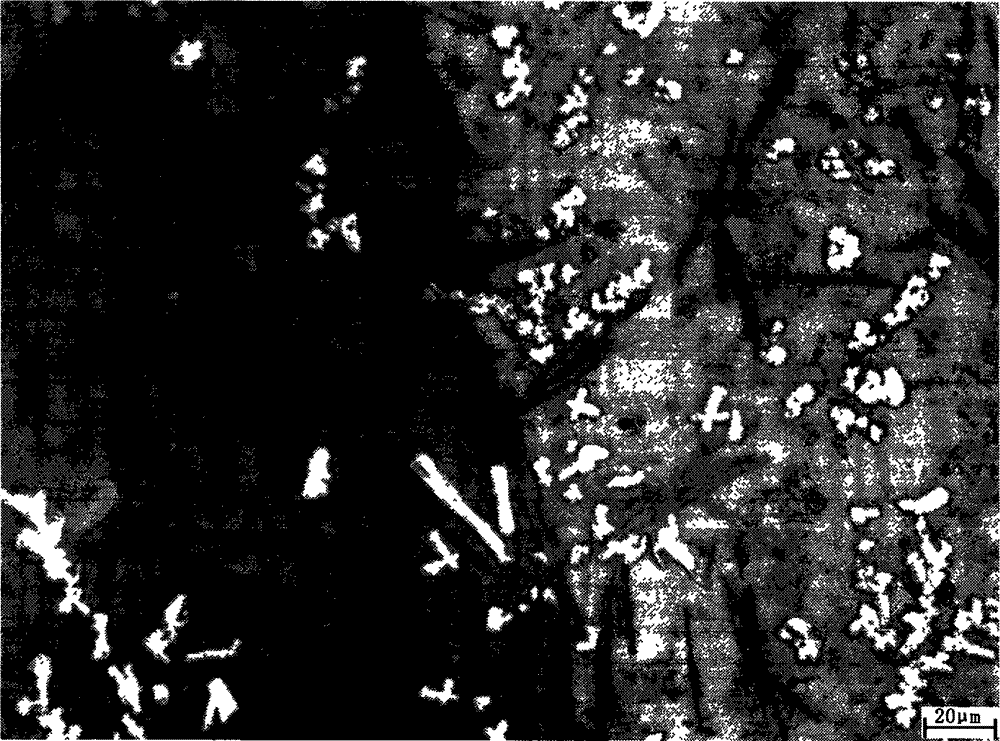

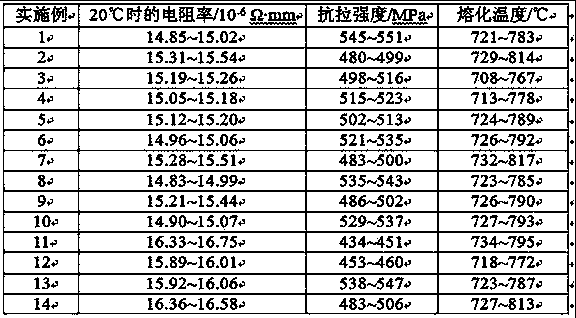

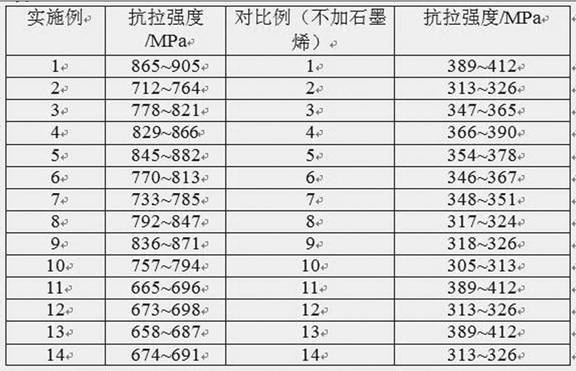

The invention discloses brazing filler metal for brazing a W-Cu composite and Fe-based alloy, a method and a brazing technique. The brazing filler metal is in a foil piece strip shape. The thickness of the brazing filler metal ranges from 50 micrometers to 100 micrometers. The brazing filler metal comprises, by weight, 6.0%-9.0% of Mn, 3.5%-5% of Co, 0.3%-1.7% of Ni, 2.0%-5.0% of Zr, 1.2%-2.8% of Ti, and the balance Cu. The brazing temperature of the brazing filler metal ranges from 1000 DEG C to 1050 DEG C, the melting temperature of the brazing filler metal is moderate, and the brazing filler metal is uniformly melted; diffusion and the interface reaction of alloy elements in the brazed connection process can be promoted through a brazing filler metal foil piece, and the wetting and spreading capacity of the brazing filler metal on the surfaces of the W-Cu composite and the Fe-based sintered alloy is improved; crystal particles are refined, residual stress is reduced, and the mechanical performance of joints is improved; the brazing technique for connecting the W-Cu composite and the Fe-based sintered alloy through the brazing filler metal is stable and reliable, vacuum brazed connection is used, a component is in a vacuum state in the heating process, the whole component does not deform, the defects such as microscopic cracks, air holes and inclusions are avoided, and the wetting and spreading capacity of the surface of the brazing filler metal is good.

Owner:JIANGSU UNIV OF SCI & TECH

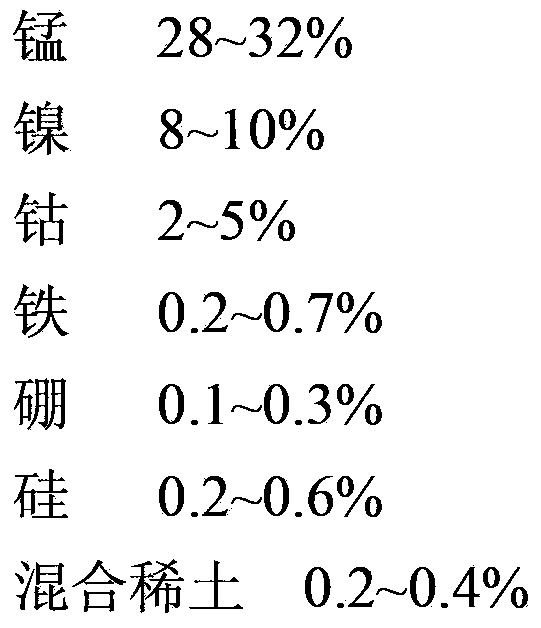

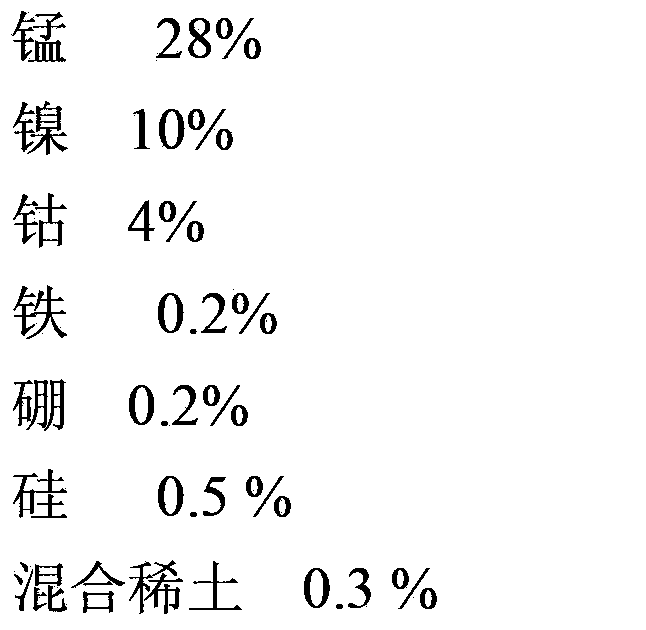

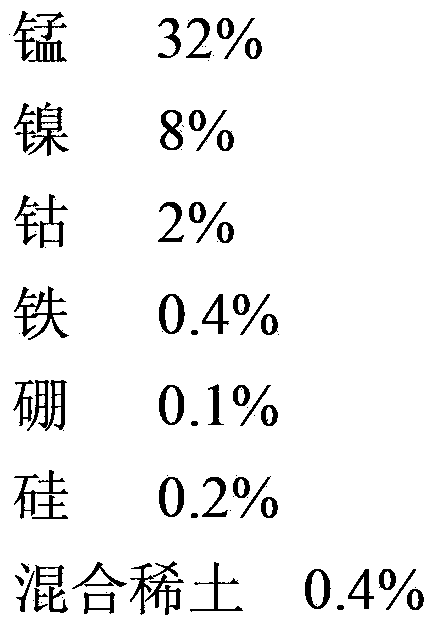

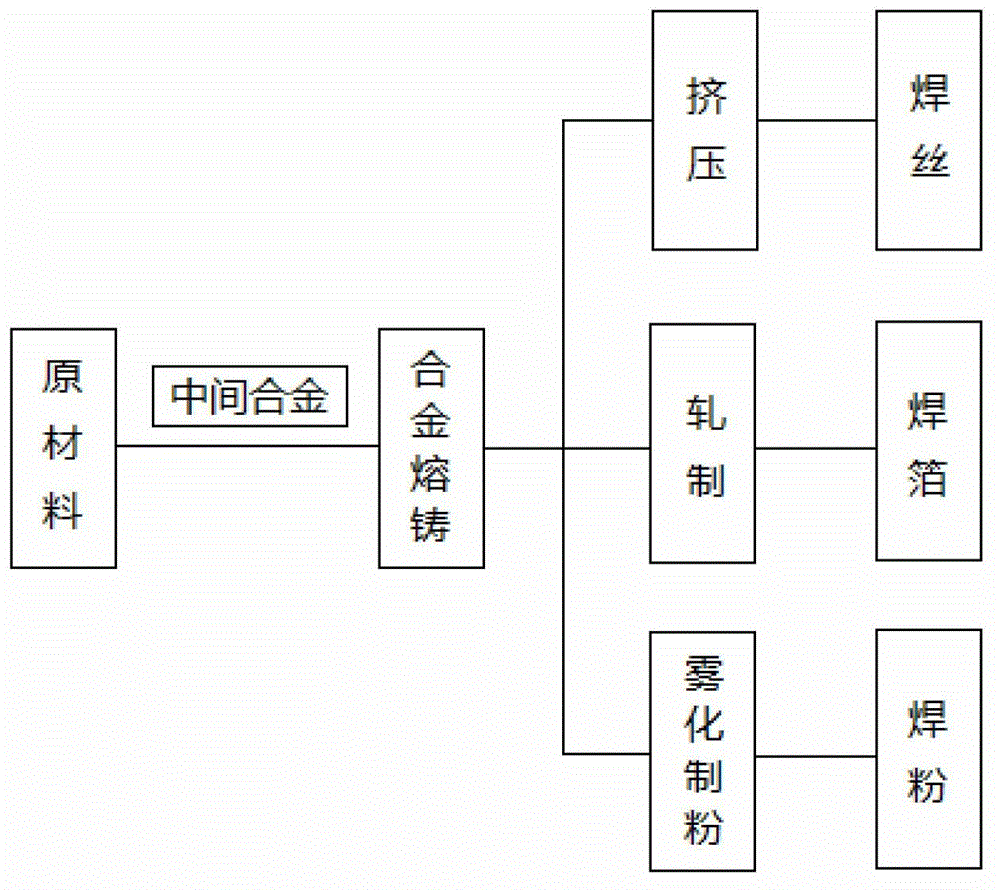

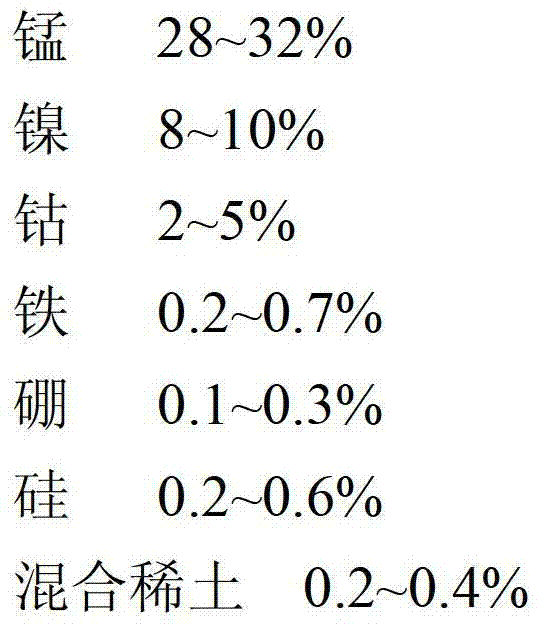

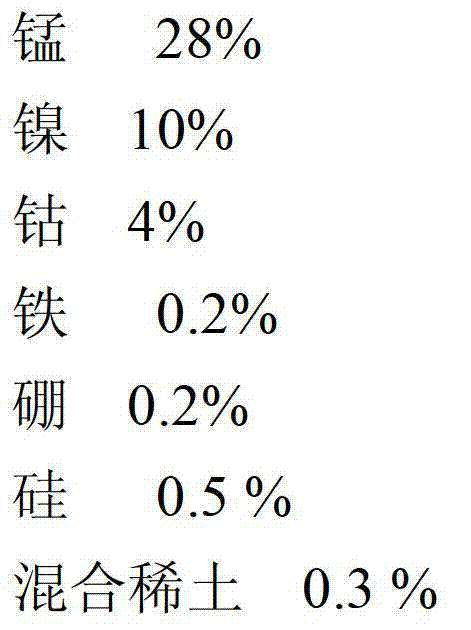

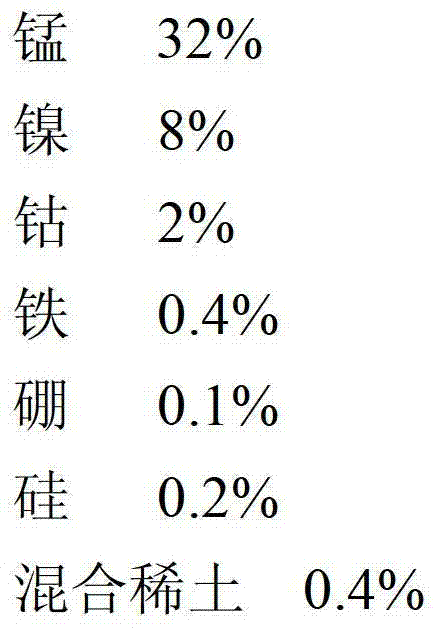

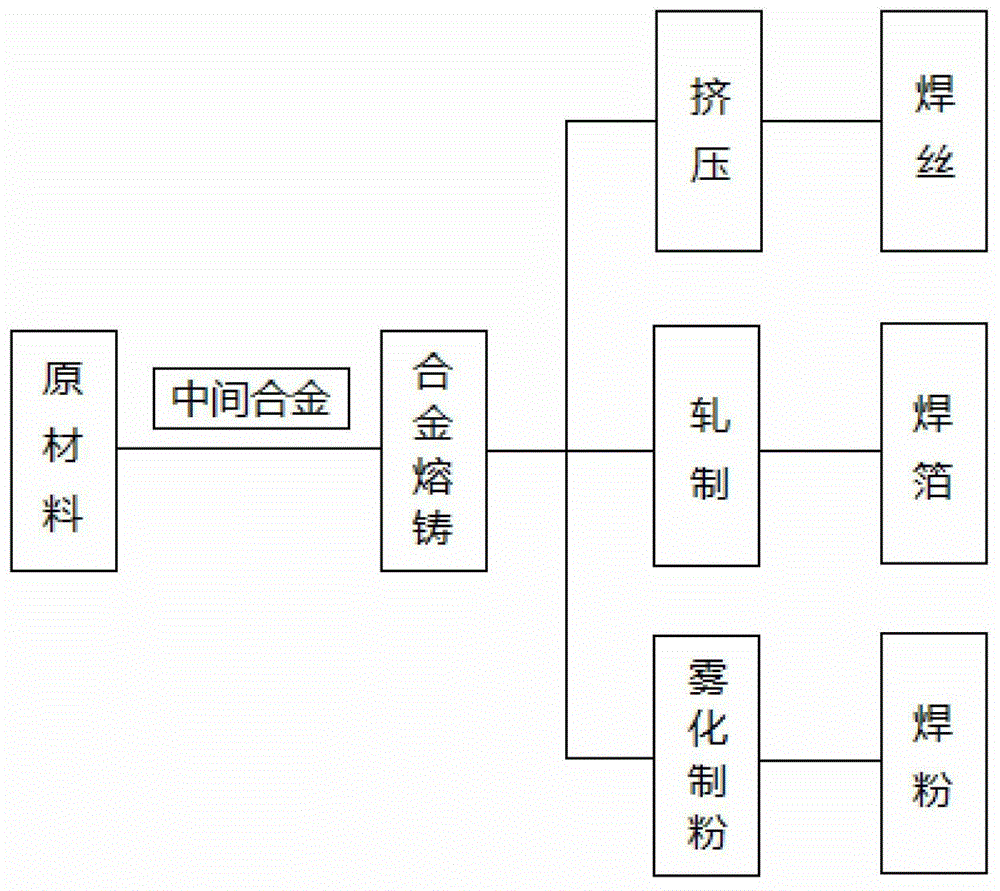

Copper-based solder and preparation method thereof

ActiveCN103358051ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCorrosionSmelting process

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Polybasic silver solder

ActiveCN103111770AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

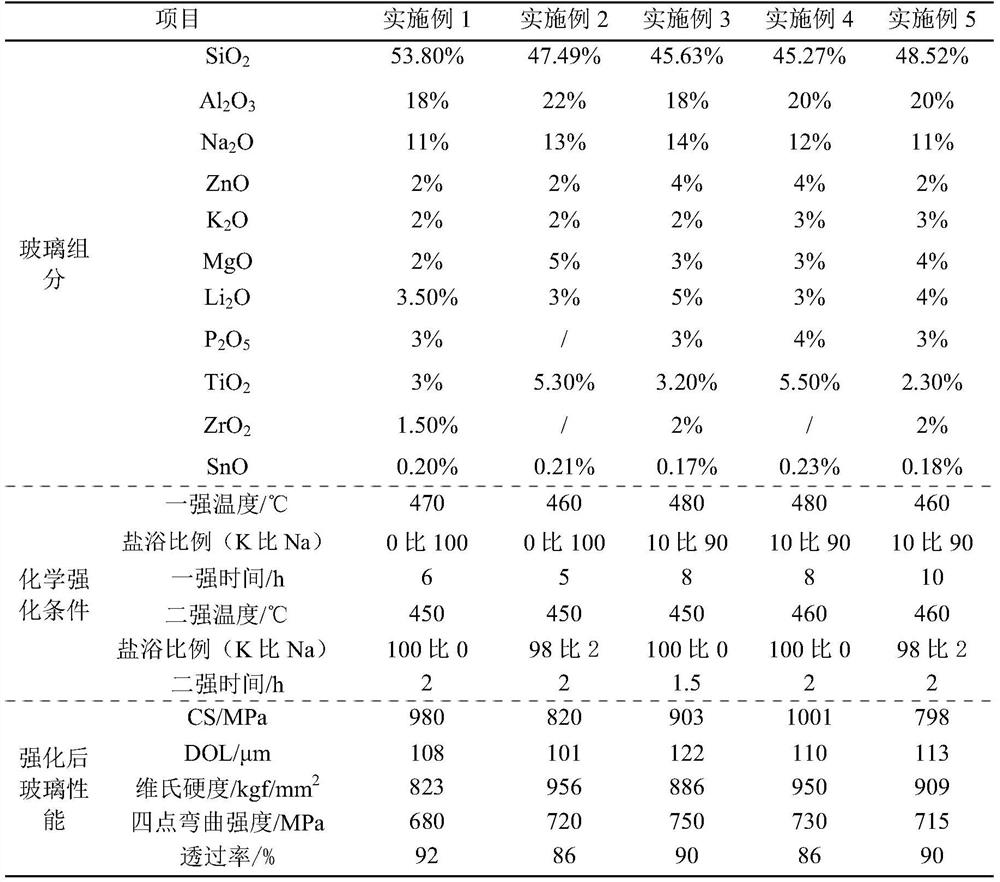

Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

InactiveCN112919813AGood chemical stabilityModerate melting temperatureGlass tempering apparatusTelephone set constructionsPotassium nitrateIon exchange

The invention discloses lithium-aluminum-silicon microcrystalline glass as well as a strengthening method and application thereof. The glass comprises the following components in percentage by mass: 45%-75% of SiO2, 10%-25% of Al2O3, 0-4% of ZrO2, 3%-5% of Li2O, 10%-18% of Na2O, 0-5% of K2O, 0-6% of P2O5, 0-7% of TiO2, 2%-7% of MgO, 0-10% of ZnO and 0-1% of SnO. The strengthening method comprises the following steps: preparing raw materials, and performing melting and molding to obtain mother glass; carrying out heat treatment to obtain microcrystalline glass; carrying out ion exchange on the microcrystalline glass in molten salt at the temperature of 390-500 DEG C for 3-10 hours to obtain primarily strengthened microcrystalline glass; and finally, soaking the glass ceramic subjected to primary strengthening in molten salt consisting of potassium nitrate and sodium nitrate for 1-2.5 hours to obtain the lithium-aluminum-silicon glass ceramic.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

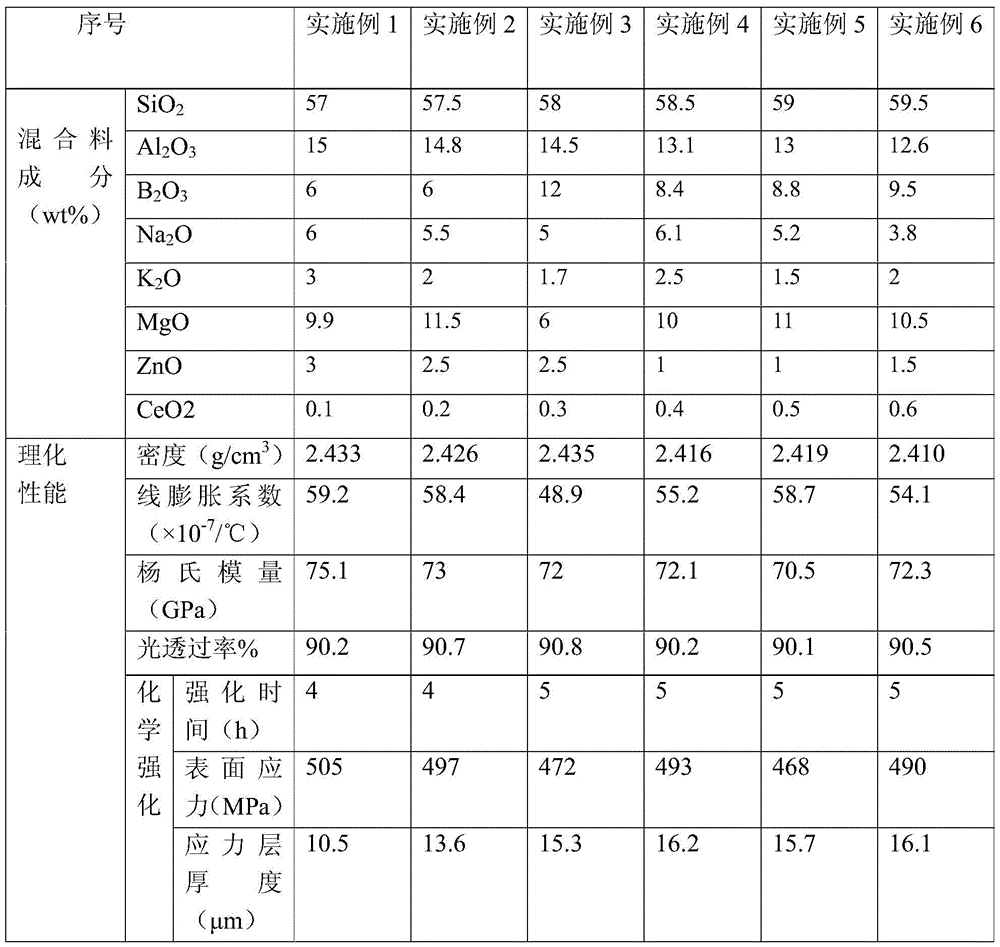

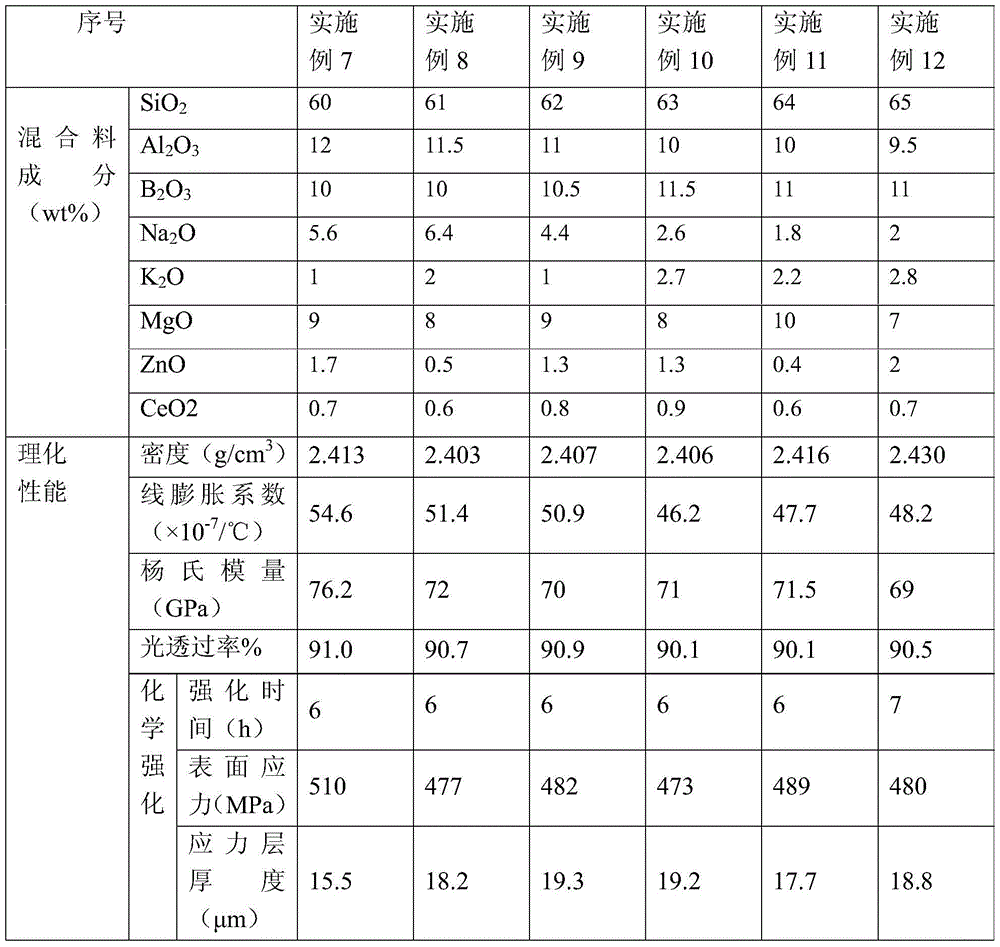

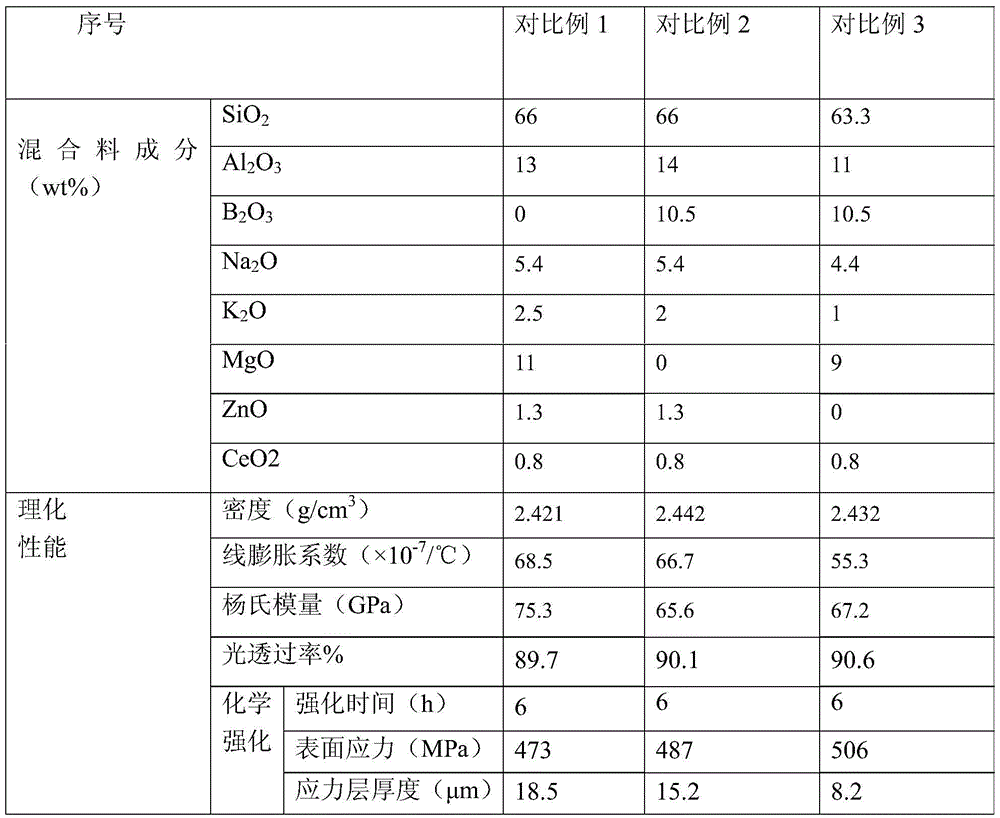

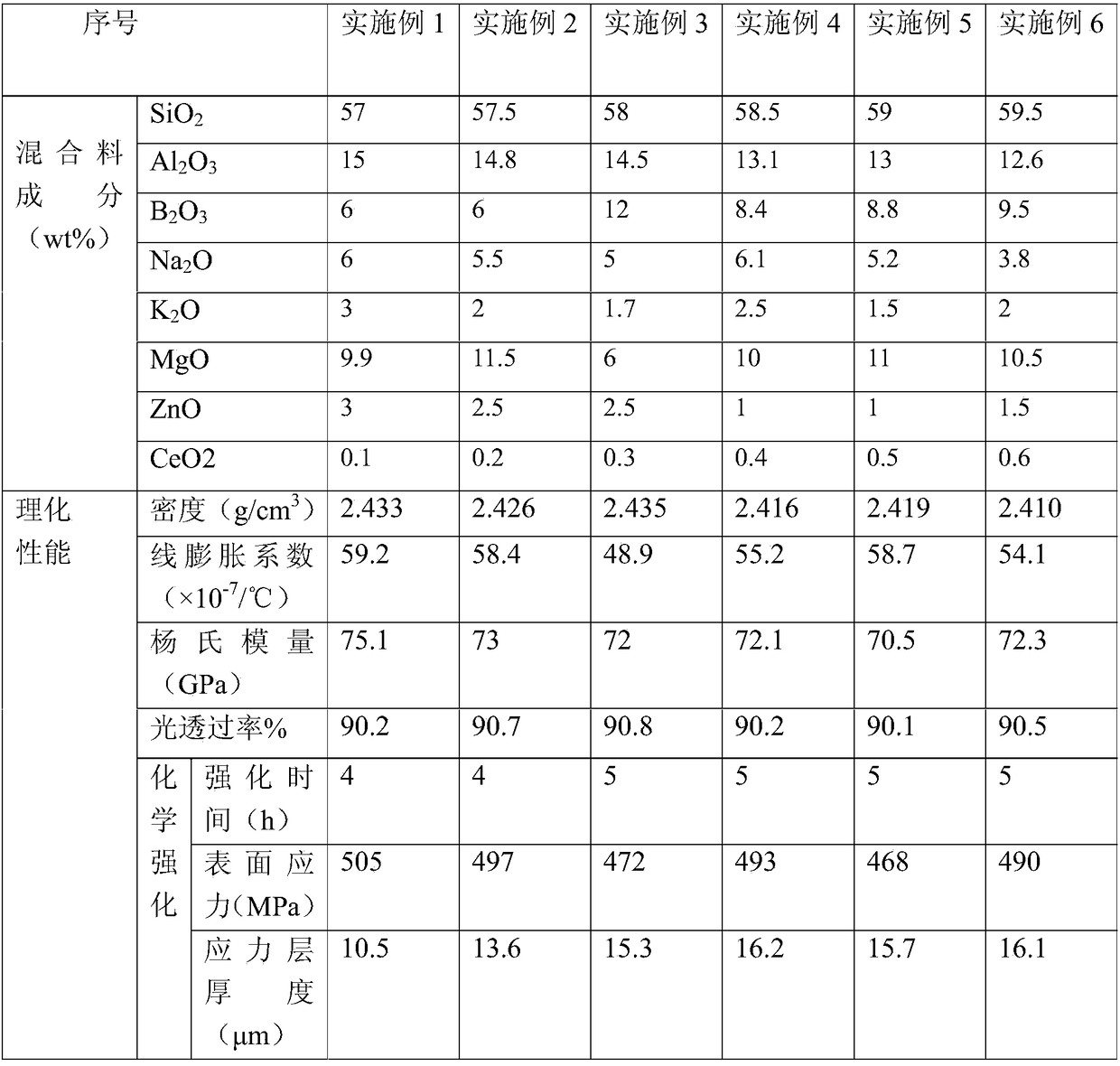

Composition for alumina silicate glass and alumina silicate glass and preparation method and application thereof

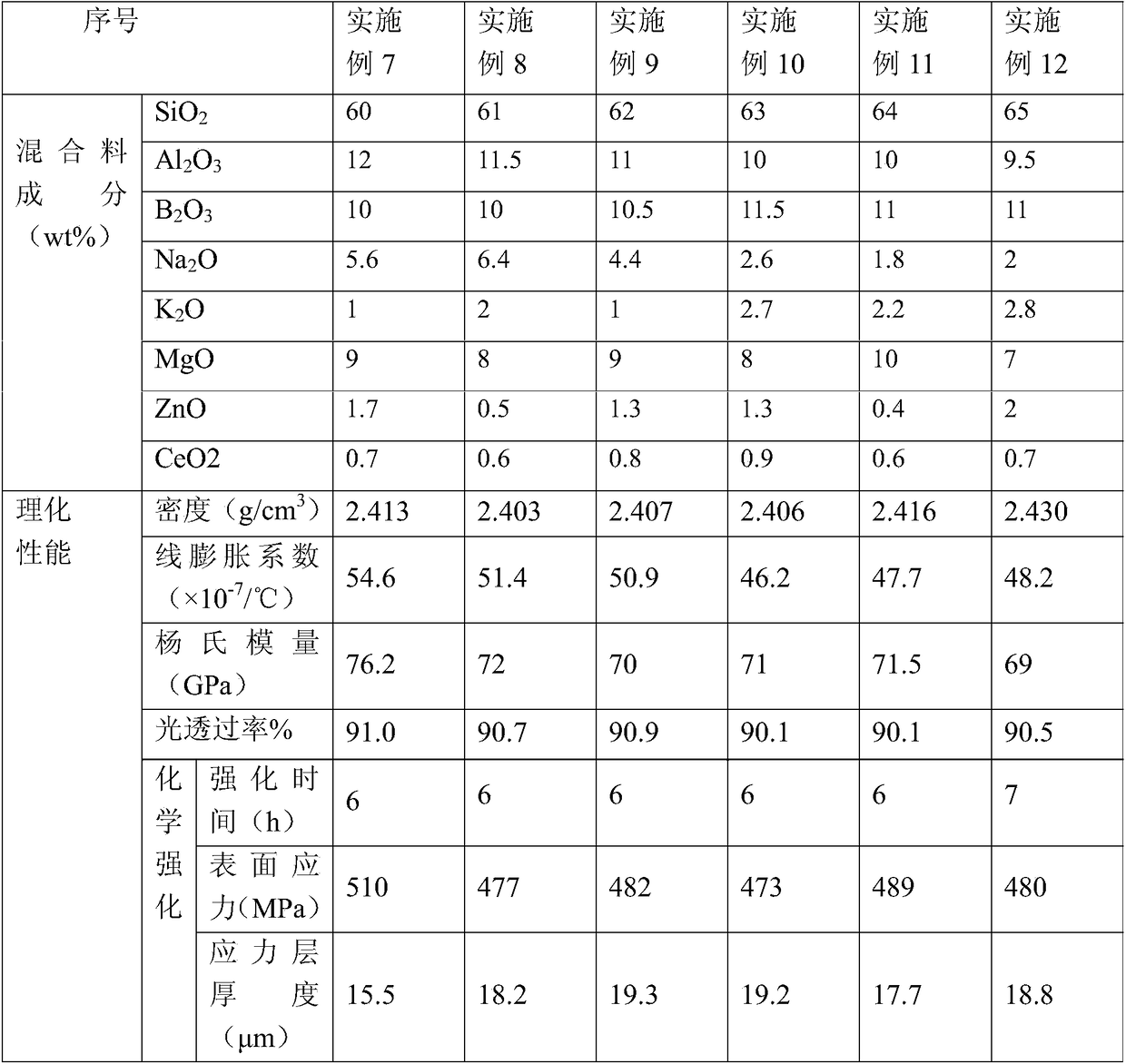

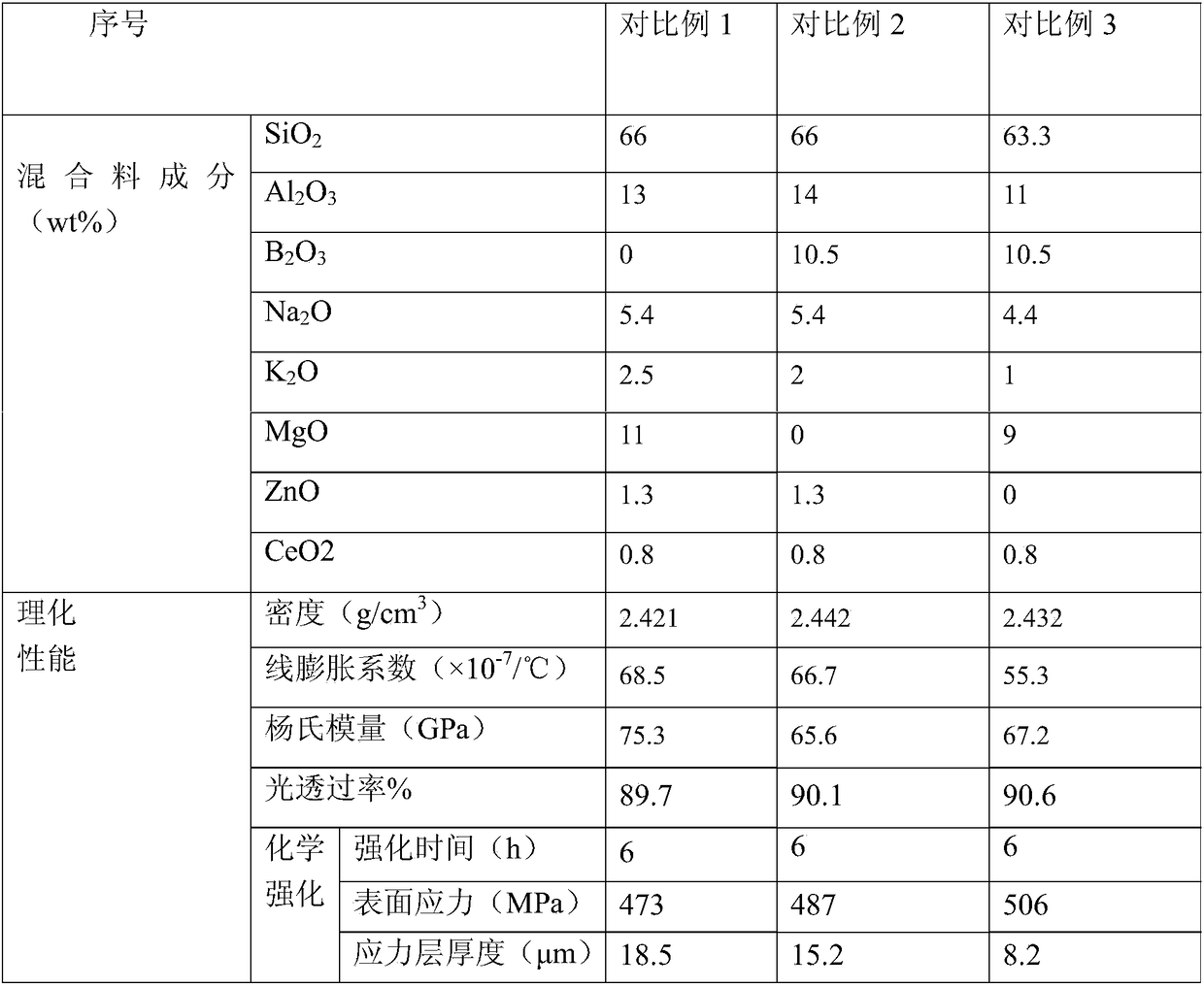

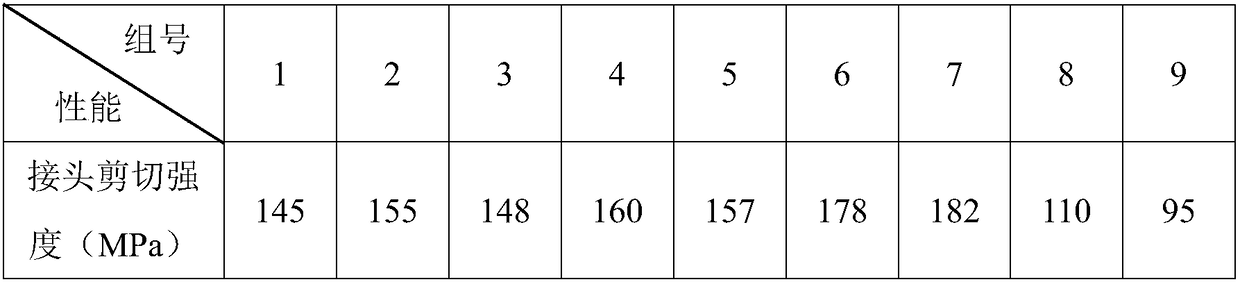

ActiveCN105481247AModerate melting temperatureReduce the presence of air bubblesSurface stressSilicate glass

The invention relates to the field of glass, and discloses a composition for alumina silicate glass and the alumina silicate glass and a preparation method and application thereof. The composition for the alumina silicate glass is prepared from SiO2, Al2O3, B2O3, Na2O,K2O, MgO, ZnO and CeO2. According to the alumina silicate glass prepared from the composition for the alumina silicate glass, bubbles are few, the linear expansion coefficient is low (the linear expansion coefficient is 45*10<-7>-60*10<-7> / DEG C within the temperature range of 25 DEG C-300 DEG C), the chemical reinforcing property is excellent (the reinforced surface stress is 450 MPa-520 MPa, and the reinforced stress layer depth is 10-20 micrometers), and the application range of the alumina silicate glass can be greatly widened when the alumina silicate glass is applied to cover plate glass for display devices.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

Sn-Zn-Ag-Ni alloy lead-free solder and preparation method thereof

ActiveCN104002058AModerate melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderingAluminium alloy

Disclosed are a Sn-Zn-Ag-Ni alloy lead-free solder and a preparation method thereof. The Sn-Zn-Ag-Ni alloy lead-free solder is mainly applied to low-temperature soldering of pure aluminum and aluminum alloy. The Sn-Zn-Ag-Ni alloy lead-free solder is composed of, by weight percentage, 8.0-10.0% of Zn, 0.5-1.5% of Ag, 0.5-1.2% of Ni and Sn as balance. The Sn-Zn-Ag-Ni alloy lead-free solder is low in melting temperature, good in soldering technological property and high in lubricity, achieves a welding deposition rate higher than 75% and a welding line tensile strength sigma b higher than or equal to 50 MPa, and is applicable to low-temperature soldering of the pure aluminum and various aluminum alloys such as 3A21, 6063 and 6061.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

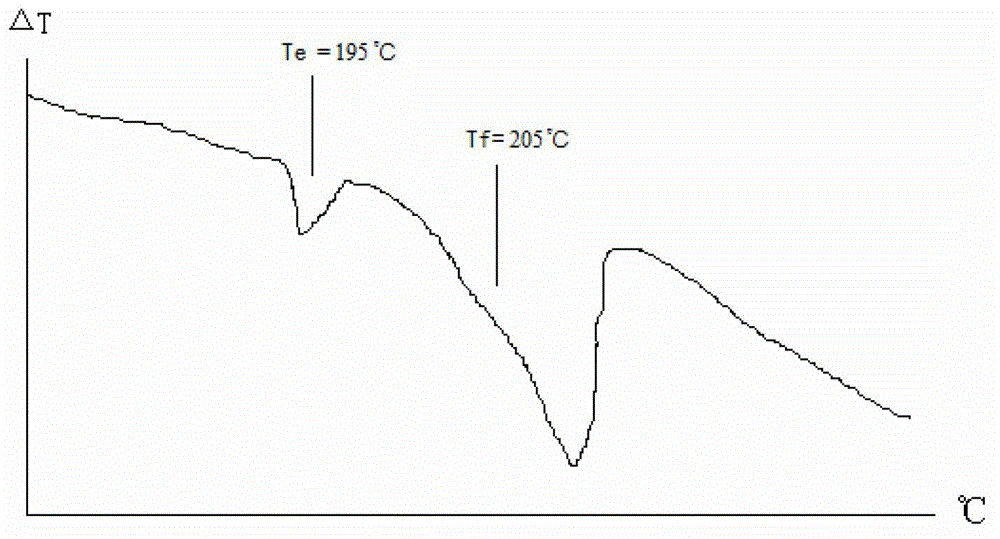

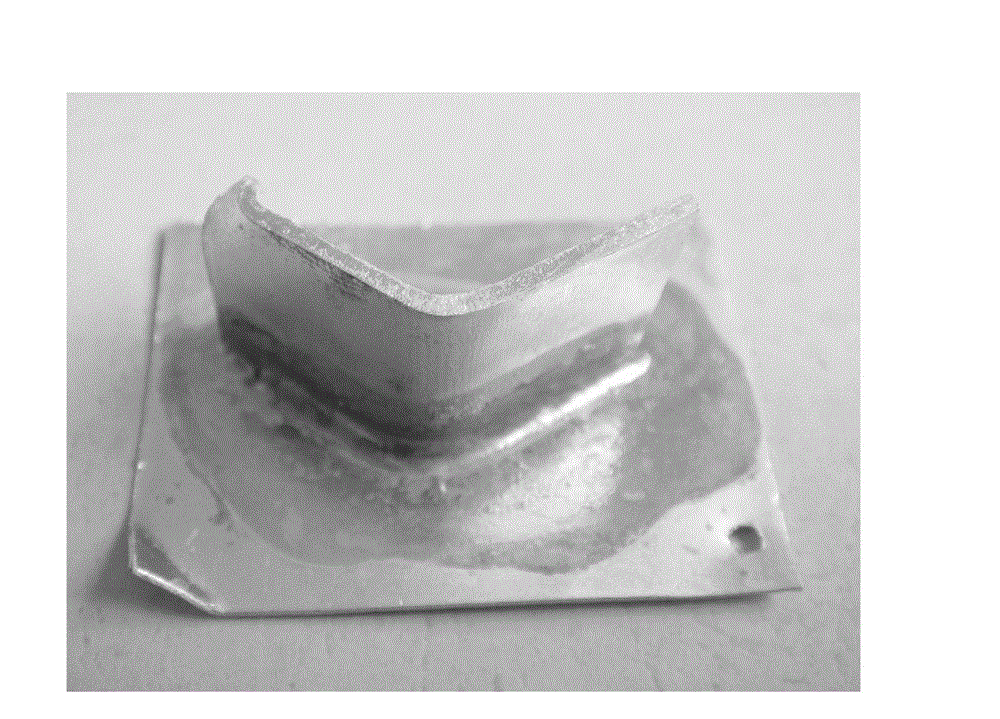

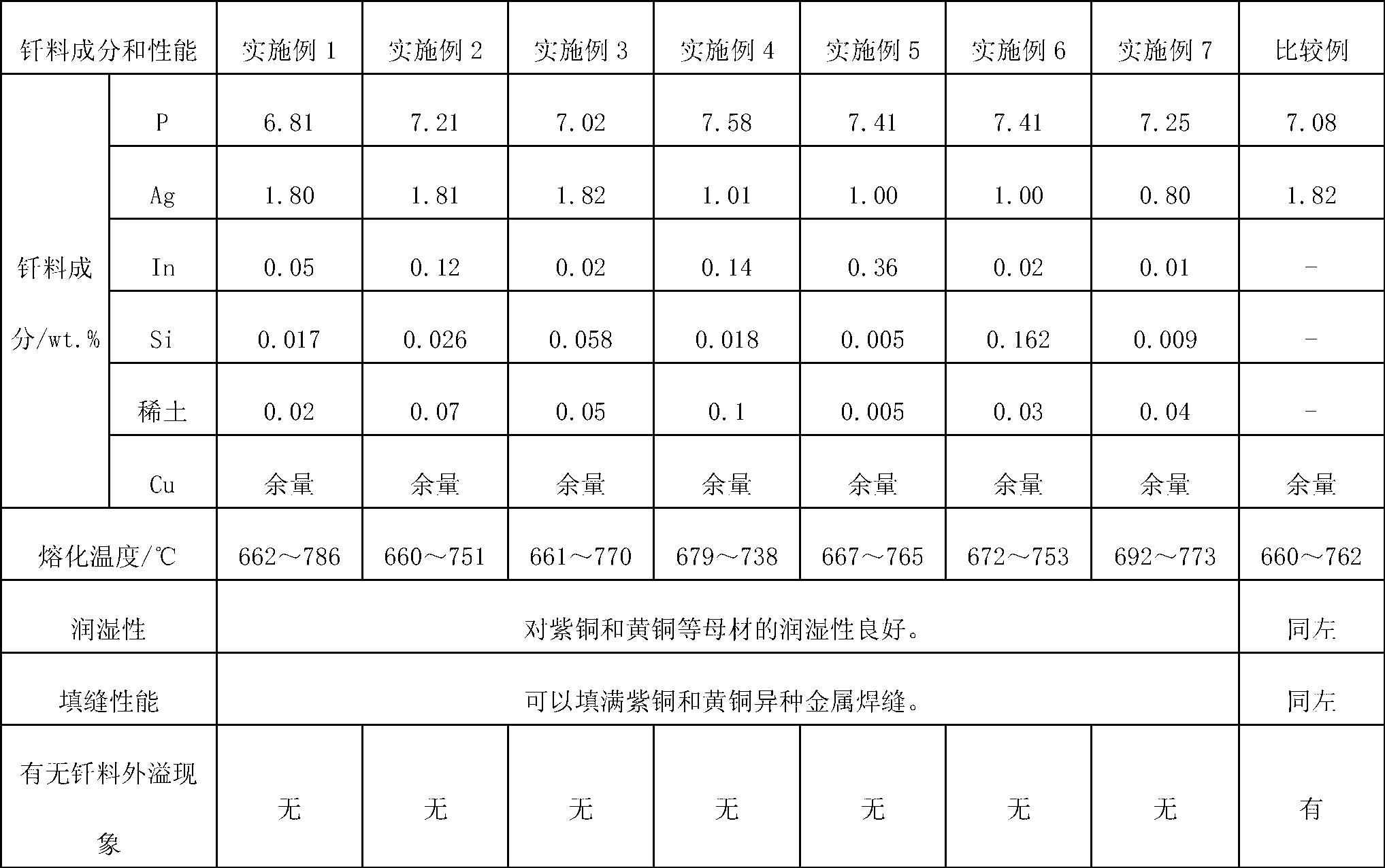

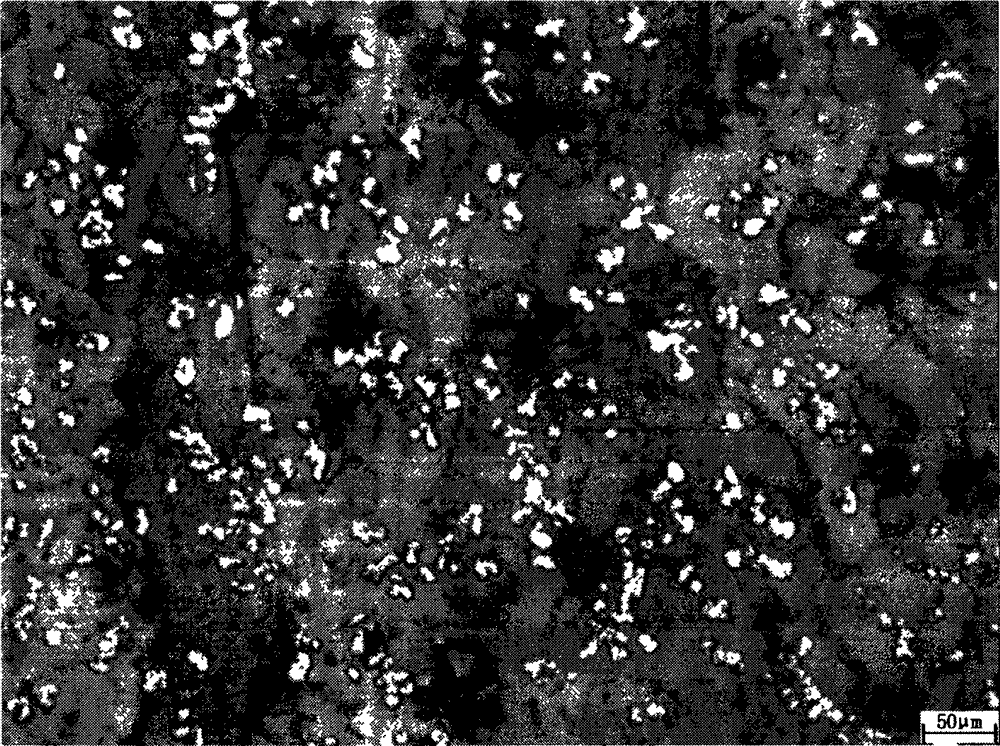

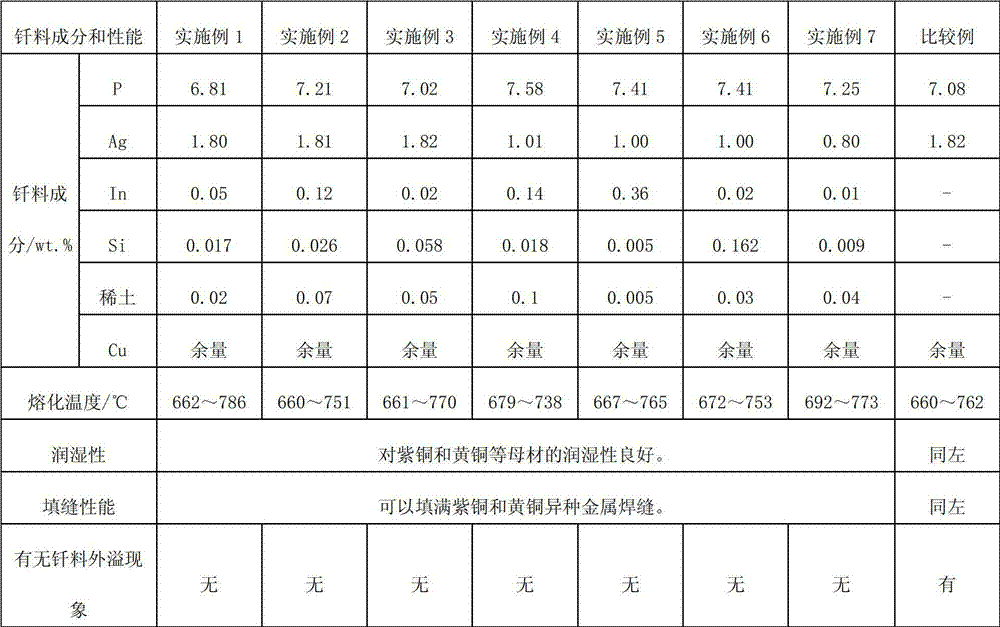

Low-silver copper-based solder free of spillover phenomenon during weld period

ActiveCN103008915ANo spillageRight melting pointWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention discloses a low-silver copper-based solder free of a spillover phenomenon during a weld period. Aiming at the defect that the spillover phenomenon of the solder often occurs when brazing is performed by using traditional low-silver copper-based solder, the invention aims to provide the low-silver copper-based solder which is controllable in flowability and is free of the spillover phenomenon of the traditional low-silver copper-based solder during a process of welding copper and copper alloy. The low-silver copper-based solder disclosed by the invention is realized through the following technical scheme: the low-silver copper-based solder free of the spillover phenomenon during the weld period comprises the following components in weight percent: 6.6-7.8 percent of phosphorus (P), 0.5-2.2 percent of silver (Ag), 0.01-0.4 percent of indium (In), 0.001-0.2 percent of silicon (Si), 0.001-0.1 percent of rare earth and the balance copper (Cu).

Owner:浙江信和科技股份有限公司

High-melting-point lead free brazing filler metal used for electronic packaging and preparation method thereof

ActiveCN103084750AEasy to getImprove economyWelding/cutting media/materialsSoldering mediaChemical compositionCopper

The invention relates to a high-melting-point lead free brazing filler metal used for electronic packaging. The high-melting-point lead free brazing filler metal used for electronic packaging is characterized in that the chemical composition of the brazing filler metal comprises, by weight, 88% to 89.5% of bismuth (Bi), 10% of silver (Ag) and 0.5% to 2% of copper(Cu). The melting temperature of the brazing filler metal is 260 DEG C to 270 DEG C. The shearing strength of the brazing filler metal is from 28 Mpa to 29.5 Mpa. Due to the fact that the brazing filler metal has an appropriate metlting temperature, the high-melting-point lead free brazing filler metal used for electronic packaging is large in potential to be a substituted brazing filler metal for a high-lead brazing filler metal.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

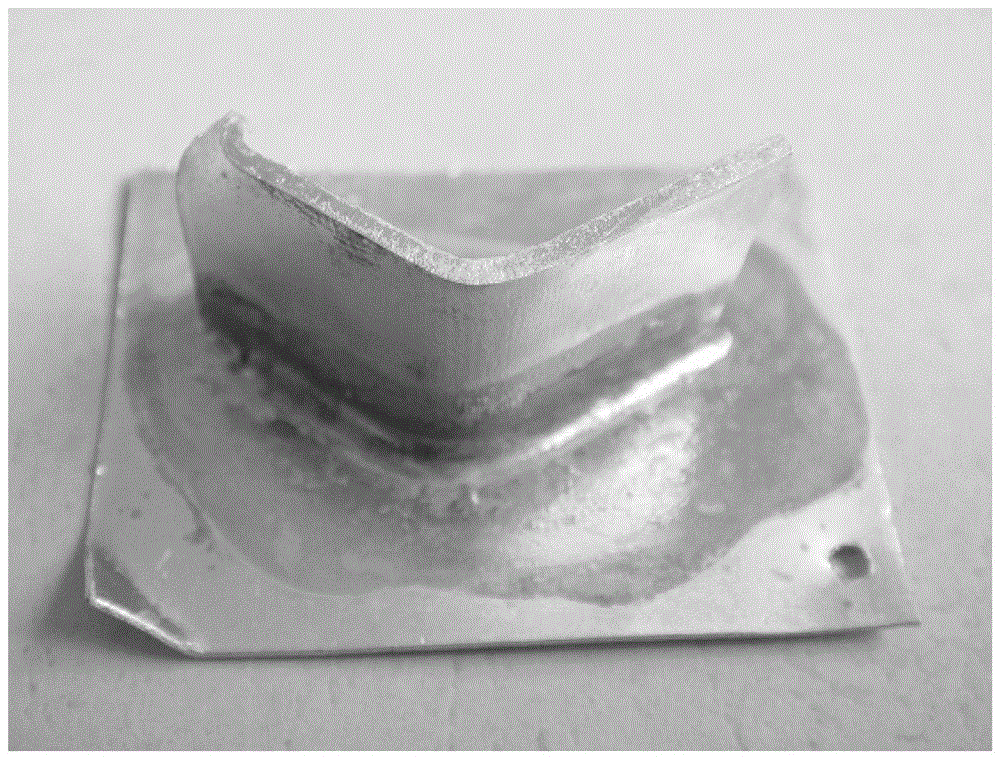

Brazing rare earth magnesium alloy brazing filler metal and preparation method and brazing process

ActiveCN106077994AUniform compositionGood wetting and spreadingWelding/cutting media/materialsSoldering mediaRare earthFiller metal

The invention discloses brazing rare earth magnesium alloy brazing filler metal and a preparation method and a brazing process. The brazing rare earth magnesium alloy brazing filler metal comprises the following element components in percentage by weight: 13-19% of Zn, 1.0-3.0% of Ni, 1.8-4.4% of Al, 0.4-1.0% of Ti, 5.1-7.0% of Cu, 0.3-0.8% of Mn, 0.004-0.01% of La, 0.004-0.01% of Nd, and the balance of Mg. The magnesium alloy brazing filler metal reaches the brazing temperature of 420-460 DEG C, and is proper in melting temperature and uniform in components; and a magnesium alloy brazing filler metal foil piece facilitates acceleration of dispersion and interface reaction of all alloy elements in the brazing connecting process, so that the wetting spreadability and the gap filling performance of the brazing filler metal in a rare earth magnesium alloy are improved, the grains are refined, the residual stress is reduced, and the joint bonding strength is improved.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

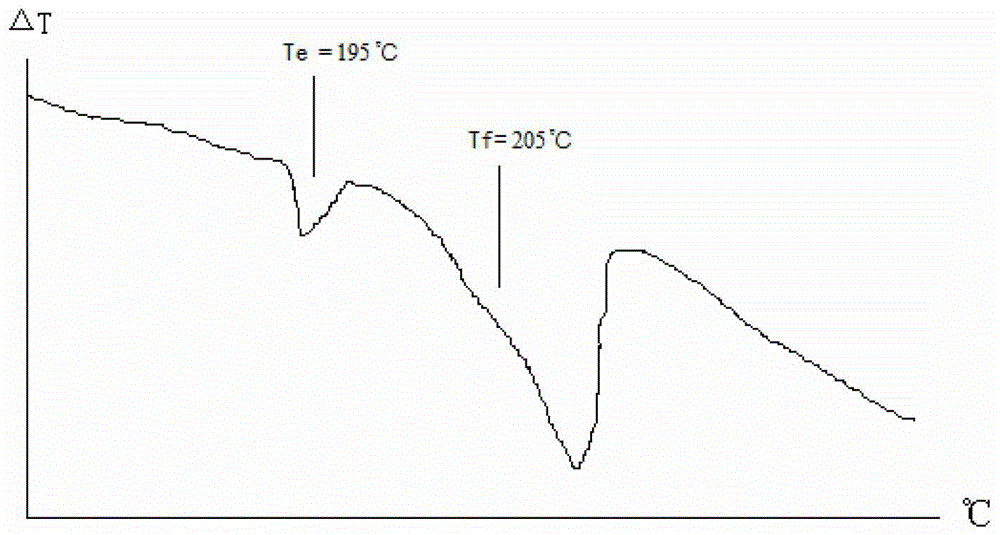

Lead-free brazing filler metal for replacing high-lead high-temperature brazing filler metal, and preparation method of lead-free brazing filler metal

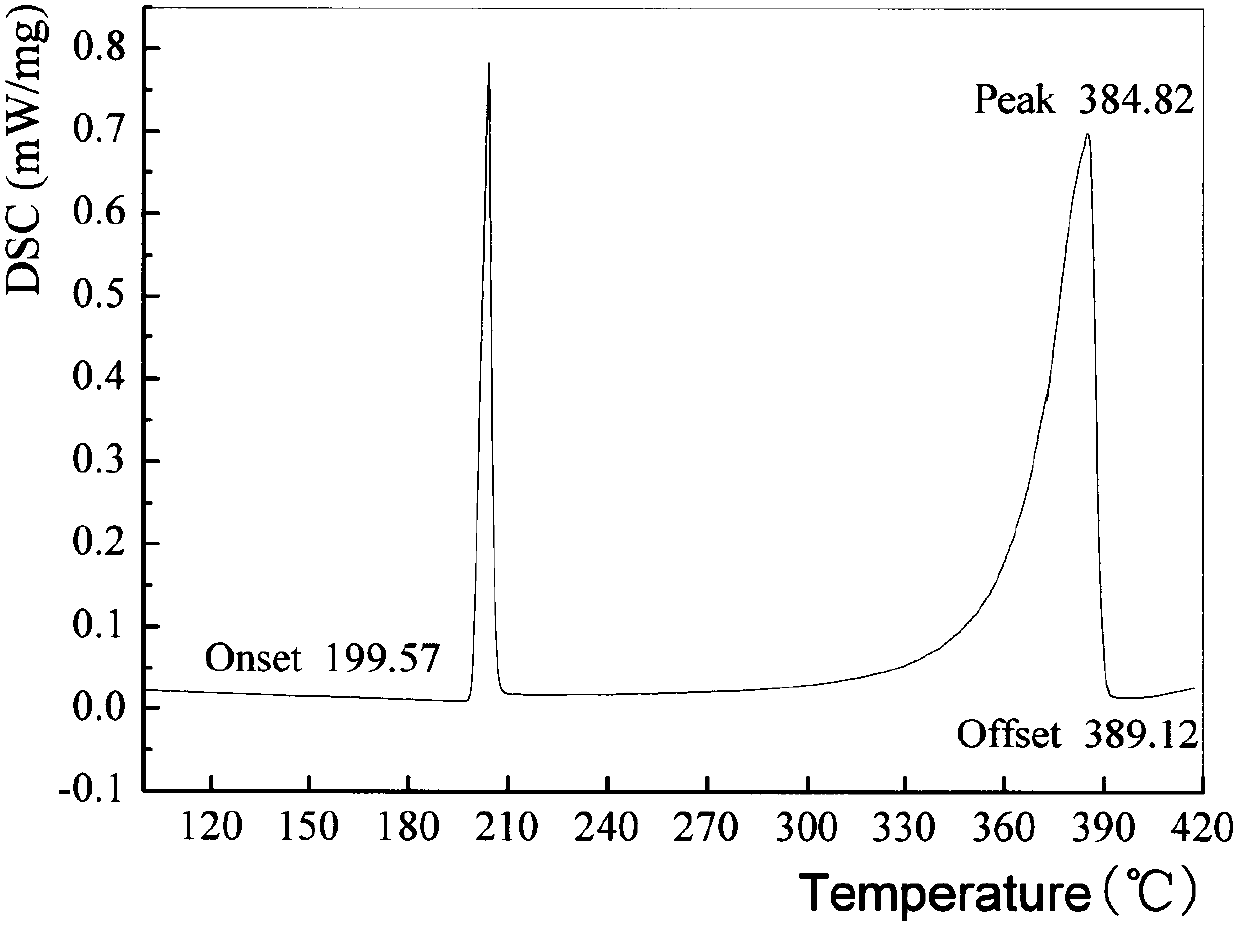

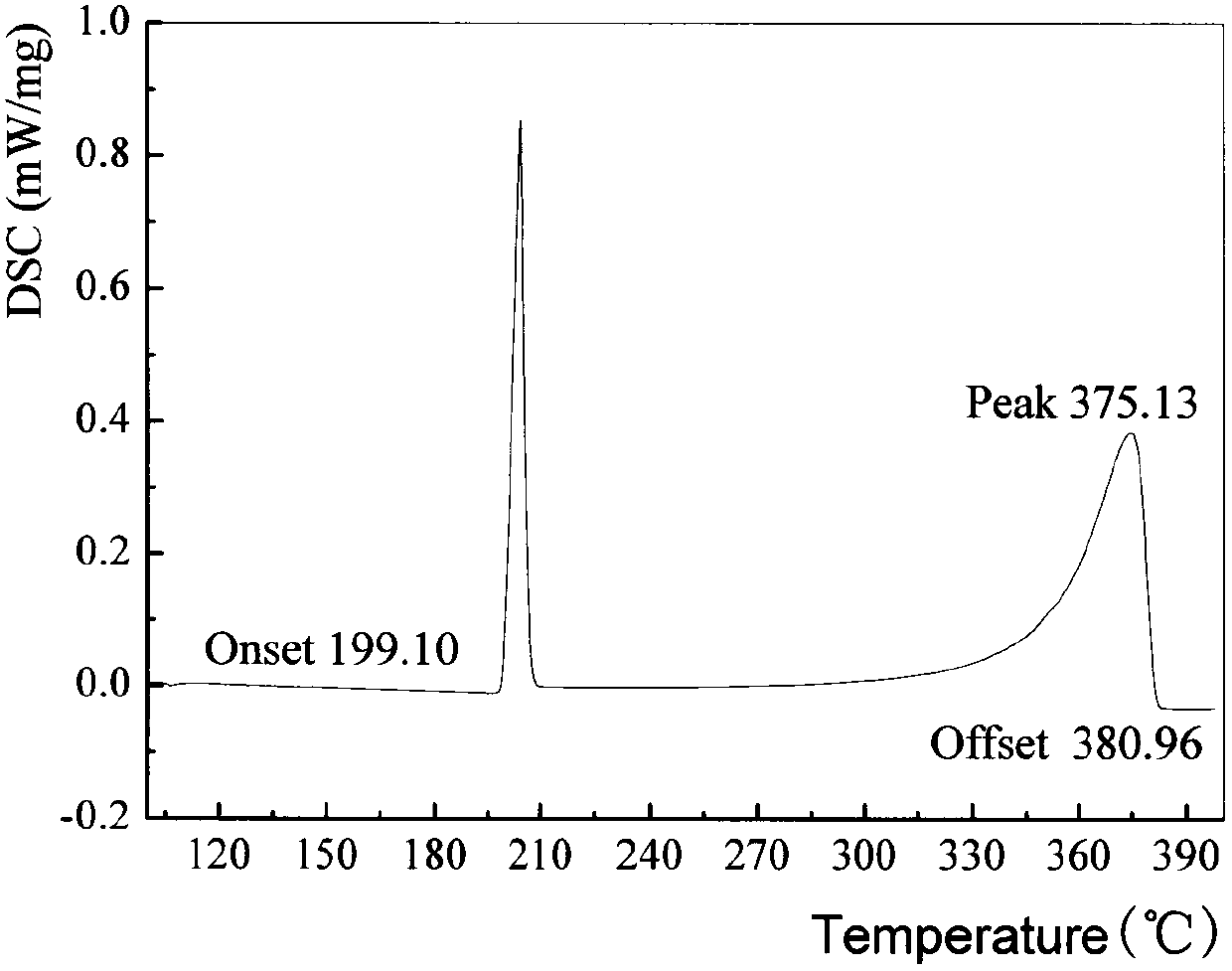

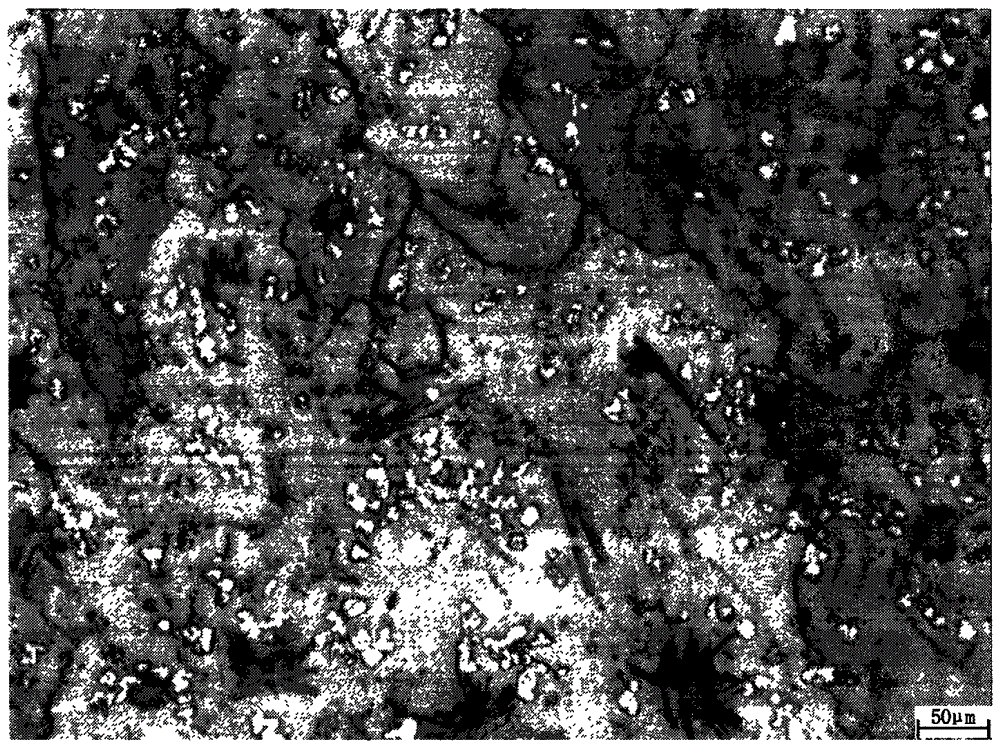

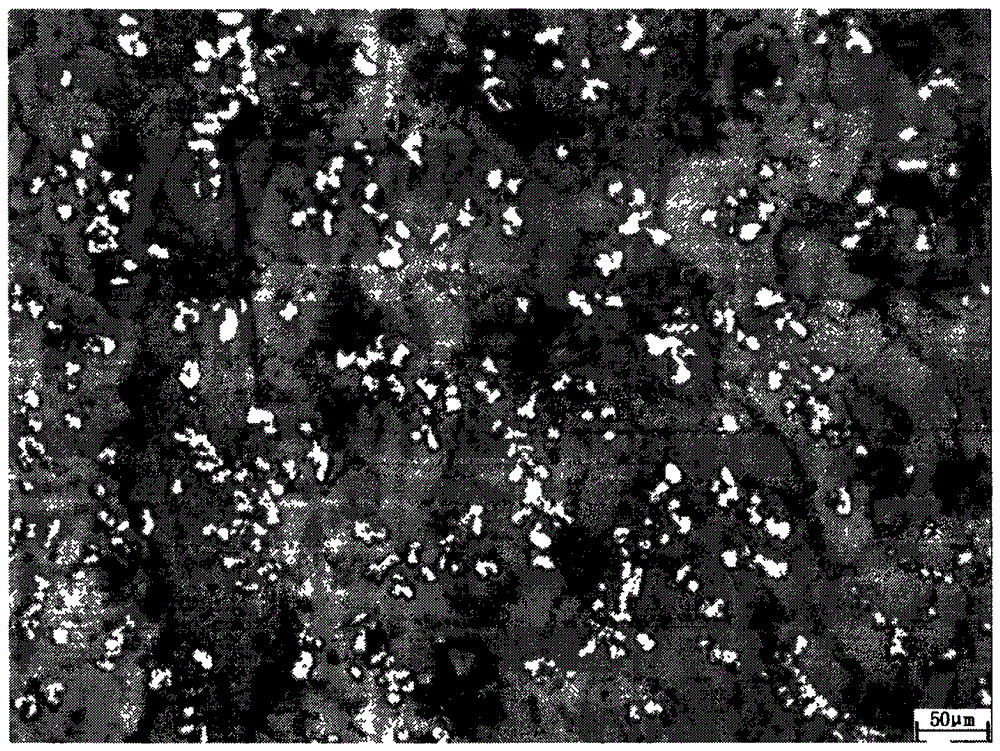

ActiveCN103223560AImprove economyEasy to getWelding/cutting media/materialsSoldering mediaChemical compositionUltimate tensile strength

The invention discloses lead-free brazing filler metal for replacing high-lead high-temperature brazing filler metal, which is characterized in that the lead-free brazing filler metal comprises the following chemical compositions: 60-80wt% of Zn and 20-40wt% of Sn, wherein the melting temperature of the lead-free brazing filler metal is 199-390 DEG C, and the shear strength is 34-39 MPa. The melting temperature of the lead-free brazing filler metal is relatively appropriate, and the potentiality of the lead-free brazing filler metal for replacing the high-lead high-temperature brazing filler metal is great.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Brazing filler metal and process for brazing molybdenum-rhenium alloy

InactiveCN106041365ASuitable melting temperatureGuaranteed high temperature performanceWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal and a process for brazing molybdenum-rhenium alloy. The brazing filler metal comprises, by weight, 7-15% of Mn, 3-6% of Co, 0-8% of Zr and the balance Cu. A method for preparing the brazing filler metal includes proportionally uniformly mixing the Cu, the Mn, the Co and the Zr with one another to obtain mixtures; preparing the brazing filler metal in the shape of a foil strap by the aid of a vacuum induction smelting furnace and a high-vacuum melt-spinning machine. The thickness of the brazing filler metal ranges from 20 micrometers to 50 micrometers. The brazing filler metal and the process have the advantages that the brazing temperature of the brazing filler metal ranges from 1020 DEG C to 1090 DEG C, the brazing filler metal has an appropriate melting temperature, the high-temperature performance of the brazing filler metal can be guaranteed, and the brazing filler metal can be uniformly molten; brazing filler metal foils are favorable for promoting diffusion and interface reaction of alloy elements in brazing connection procedures, the wetting and spreading capacity of the brazing filler metal on the surfaces of the molybdenum-rhenium alloy can be improved, crystalline grains can be refined, residual stress can be reduced, and the mechanical properties of connectors can be improved.

Owner:JIANGSU UNIV OF SCI & TECH

Magnesium alloy brazing filler metal based on rare earth magnesium alloy braze as well as preparation method and brazing technology of magnesium alloy brazing filler metal

ActiveCN106001984AUniform compositionGood wetting and spreadingWelding/cutting media/materialsSoldering mediaInterfacial reactionAdditive ingredient

The invention discloses a magnesium alloy brazing filler metal based on rare earth magnesium alloy braze as well as a preparation method and a brazing technology of the magnesium alloy brazing filler metal. The magnesium alloy brazing filler metal comprises the following elements in percentage by weight: 8.8%-11.5% of Zn, 8.2%-9.3% of Al, 3.8%-5.5% of Ni, 1.0%-3.0% of Ag, 1.0%-2.0% of Ti, 0.8%-2.2% of Cu, 0.5%-1.0% of Mn and the balance of Mg. The rotary feeding device is moderate in melting temperature and uniform in ingredients; application of a magnesium alloy brazing filler metal chaff facilitates diffusion and interfacial reaction of all alloy elements during the brazed connection process, improves wetting spreadability and gap filling performance of the brazing filler metal in rare earth magnesium alloy, refines grain, reduces residual stress, and improves the bonding strength of joints.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

Covering agent for aluminum alloy smelting and preparing method of covering agent

InactiveCN108018449AImprove insulationPrevent secondary oxidation effectPlastic bagSodium fluosilicate

The invention discloses a covering agent for aluminum alloy smelting and a preparing method of the covering agent. The covering agent is characterized by comprising, by mass, 20-40 parts of potassiumchloride, 20-40 parts of sodium chloride, 5-15 parts of lithium chloride, 3-5 parts of potassium fluoride, 1-3 parts of sodium hydrogen sulfate and 3-5 parts of sodium fluosilicate. The preparing method comprises the following steps that firstly, the components are prepared according to the weight part; secondly, the raw materials are sufficiently mixed and stirred evenly; thirdly, the mixture obtained in the second step is placed in a baking furnace to be dried, and the drying temperature ranges from 290 DEG C to 300 DEG C; fourthly, the dried mixture is pulverized, and powder of 80-100 meshes is formed through sieving; and fifthly, a waterproof plastic bag is used for packaging. According to the covering agent preparing technology, heat preservation of the covering agent can be effectively improved, the melting temperature is proper, and melting is rapid; a layer of oily film is formed on the surface of a casting, and casting oxidization burnout and air suction can be effectively prevented. Strong chemical stability and heat stability are achieved, molten aluminum and a furnace lining are not corroded, and original components and performance of the alloy are guaranteed.

Owner:徐州轩辕铝业有限公司

A kind of copper base solder and preparation method thereof

ActiveCN103358051BEasy to processReduced processing performanceWelding/cutting media/materialsSoldering mediaRare earthManganese

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

A kind of composition for aluminosilicate glass, aluminosilicate glass and its preparation method and application

ActiveCN105481247BModerate melting temperatureReduce the presence of air bubblesSurface stressSilicate glass

The invention relates to the field of glass, and discloses a composition for aluminosilicate glass, aluminosilicate glass and a preparation method and application thereof. The composition for aluminosilicate glass of the present invention contains SiO2, Al2O3, B2O3, Na2O, K2O, MgO, ZnO and CeO2. The aluminosilicate glass prepared by using the composition for aluminosilicate glass has fewer bubbles and a low coefficient of linear expansion (the coefficient of linear expansion in the range of 25-300°C is 45×10-7-60×10- 7 / ℃), excellent chemical strengthening performance (the surface stress after strengthening is 450-520MPa, and the depth of the stress layer is 10-20μm), and when it is applied to the cover glass for display devices, it can greatly expand its application range.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

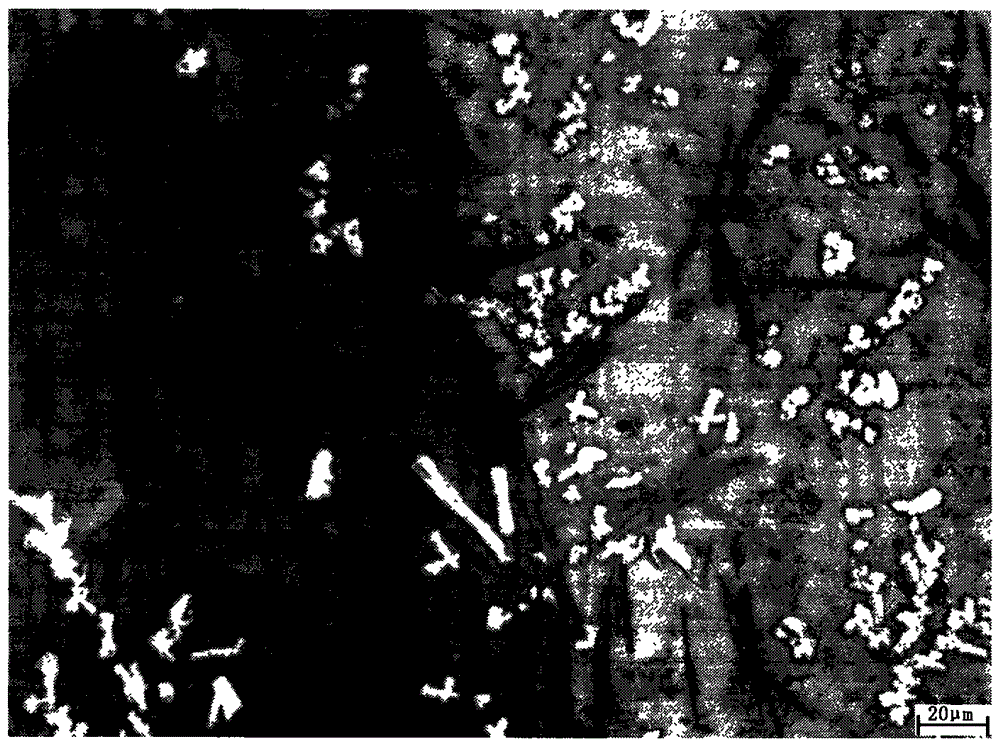

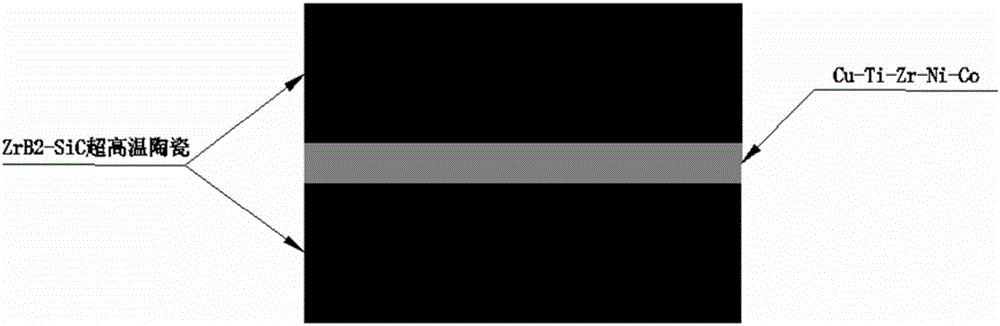

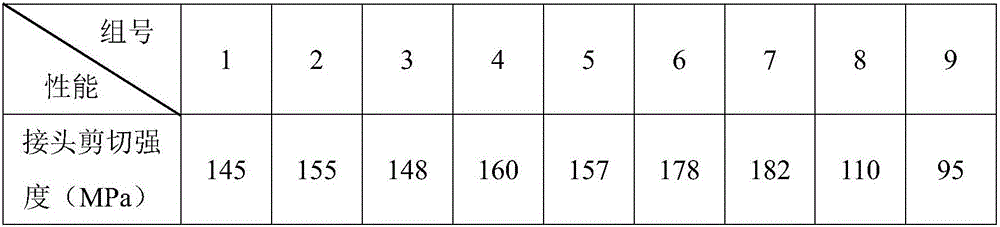

A brazing material used for Zrb2-sic ultra-high temperature ceramic brazing and a brazing process using the brazing material

ActiveCN106112310BModerate meltingModerate melting temperatureWelding/cutting media/materialsSoldering mediaFiller metalPollution

The invention discloses brazing filler metal for brazing ZrB2-SiC ultrahigh-temperature ceramic and a process for brazing by using the brazing filler metal. The brazing filler metal comprises Cu, Ti, Zr, Ni and Co. The brazing process comprises the following steps: various raw materials are mixed to manufacture a brazing material to assemble on the ZrB2-SiC ultrahigh-temperature ceramic to form a welding sample; and the welding sample is positioned in vacuum brazing equipment, is heated to reach 910-1000 DEG C by a heating-insulation-heating-insulation mode, and is cooled to reach the room temperature. The brazing filler metal is proper in melting temperature and uniform in melting; and meanwhile, the vacuum brazing process is adopted, so that parent metal is located in a vacuum state in the heating process without the deformation and grain thickening phenomenon and without generating such problems as oxidation and pollution, the operation is stable and reliable, the surface wetting spreadability is better, the brazing gap filling is facilitated, the joint comprehensive performance is improved, and a brazing joint with excellent performance can be obtained.

Owner:JIANGSU UNIV OF SCI & TECH

Magnesium alloy solder based on rare earth magnesium alloy brazing, preparation method and brazing process

ActiveCN106001984BUniform compositionGood wetting and spreadingWelding/cutting media/materialsSoldering mediaInterfacial reactionUltimate tensile strength

The invention discloses a magnesium alloy brazing filler metal based on rare earth magnesium alloy braze as well as a preparation method and a brazing technology of the magnesium alloy brazing filler metal. The magnesium alloy brazing filler metal comprises the following elements in percentage by weight: 8.8%-11.5% of Zn, 8.2%-9.3% of Al, 3.8%-5.5% of Ni, 1.0%-3.0% of Ag, 1.0%-2.0% of Ti, 0.8%-2.2% of Cu, 0.5%-1.0% of Mn and the balance of Mg. The rotary feeding device is moderate in melting temperature and uniform in ingredients; application of a magnesium alloy brazing filler metal chaff facilitates diffusion and interfacial reaction of all alloy elements during the brazed connection process, improves wetting spreadability and gap filling performance of the brazing filler metal in rare earth magnesium alloy, refines grain, reduces residual stress, and improves the bonding strength of joints.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

A process for brazing SIC-based composite materials using brazing materials

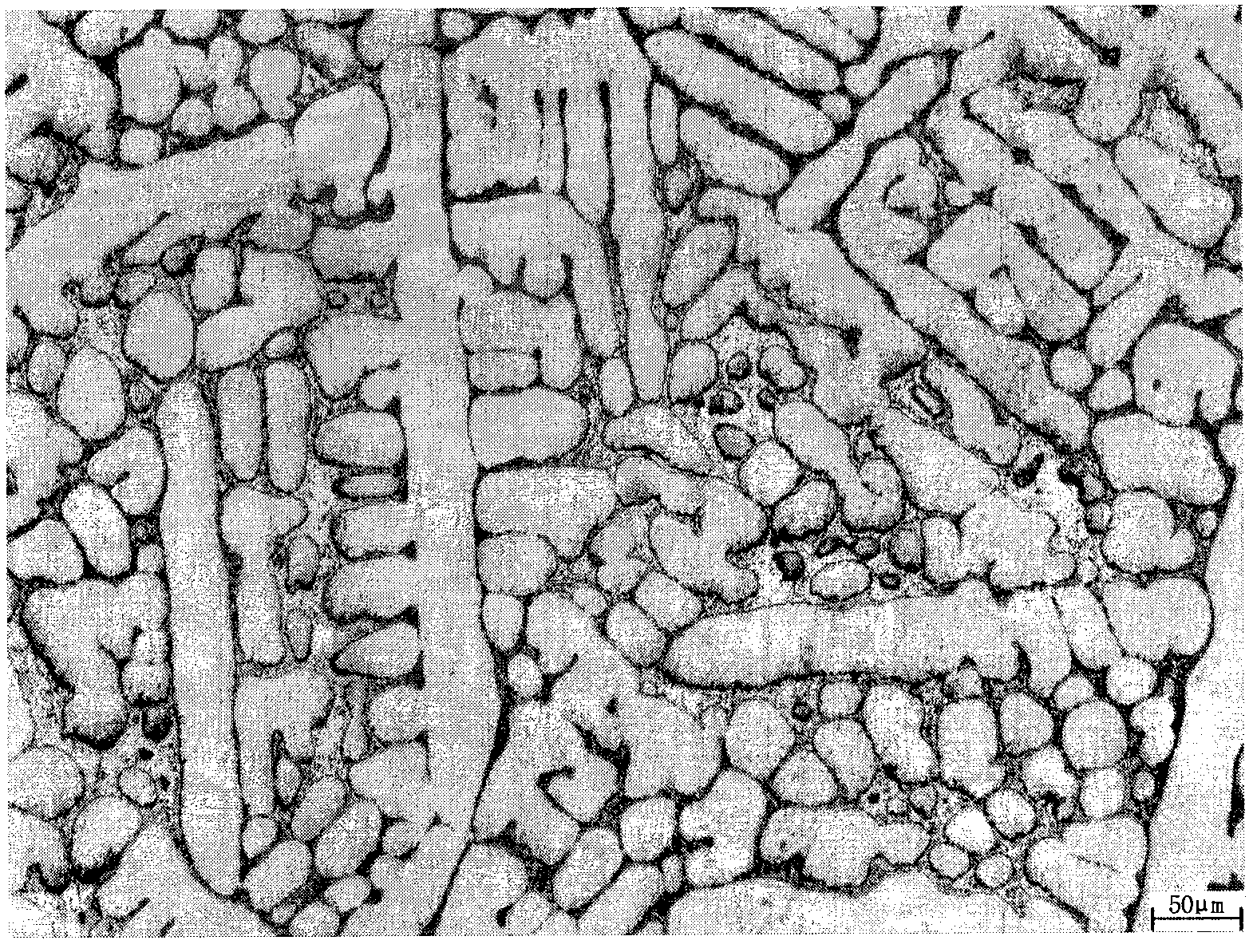

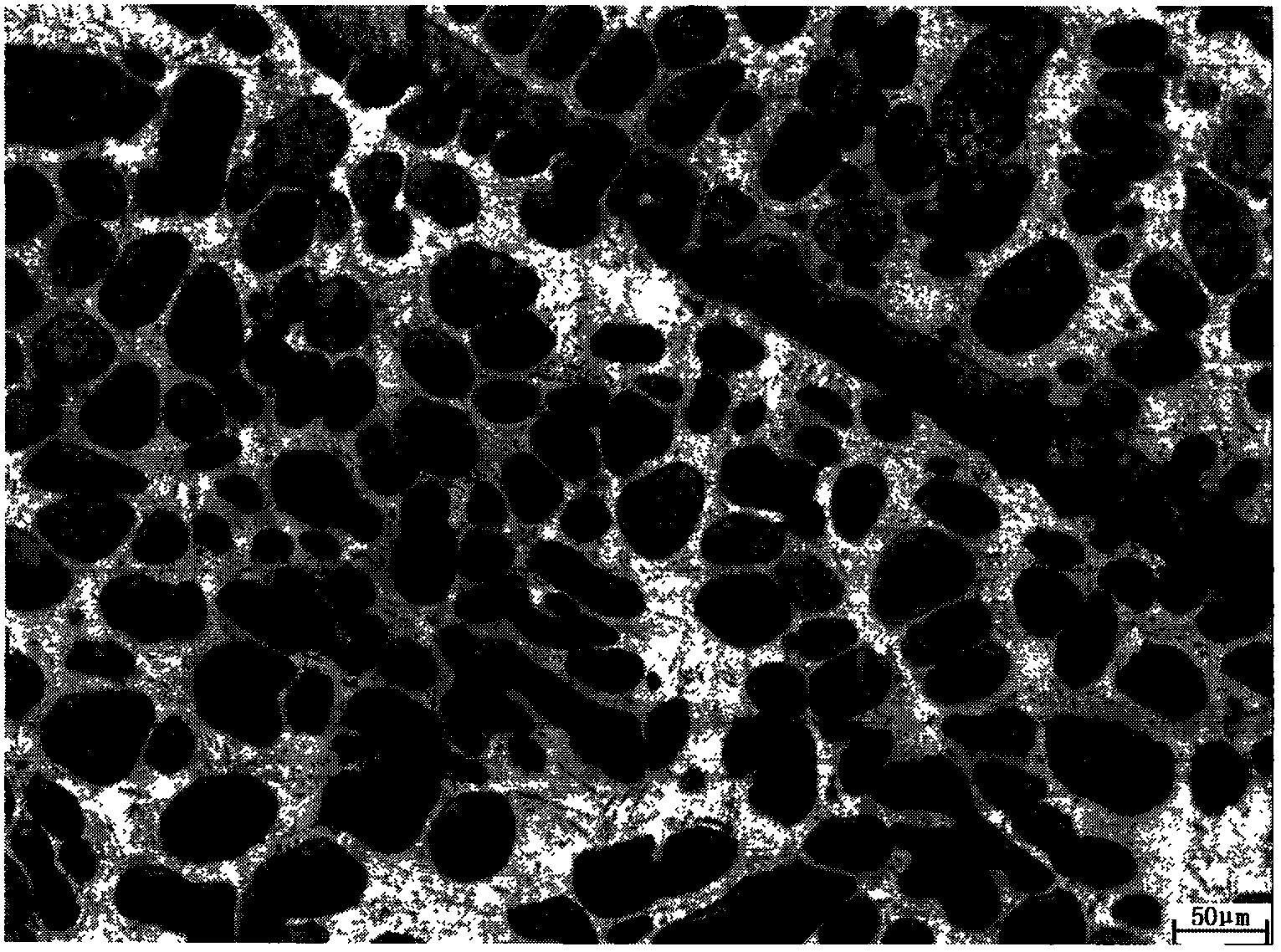

ActiveCN106378506BEvenly meltedFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsSoldering mediaBase metalFiller metal

The invention discloses brazing filler metal for brazing a SiC-based composite material and a brazing process. The brazing filler metal comprises the following elements in percentages by mass: 39-43% of Co, 8.6-12.1% of Ni, 23.6-27% of Nb and 18.5-22% of V. The melting temperature of the brazing filler metal is moderate, and the brazing filler metal is melted uniformly; by the foil-piece-shaped amorphous brazing filler metal, element diffusion and interface reaction are facilitated in a brazing connection process, metallurgical solid solution reaction between the brazing filler metal and the SiC-based composite material is facilitated, residual stress in a brazing joint is relieved effectively, and mechanical properties of the joint are improved. According to the brazing process, base metal is in a vacuum state in a heating process by vacuum brazing connection, deformation and grain coarsening do not exist, and problems of oxidation, pollution and the like are avoided; and the vacuum brazing process is stable and reliable, wetting spreadability of the surface is good, filling of brazing seams is facilitated, overall performance of the joint is improved, and therefore, the brazing joint with excellent performance can be obtained.

Owner:江苏元沣机械设备有限公司

A kind of highly conductive silver-based melt material and its melting method

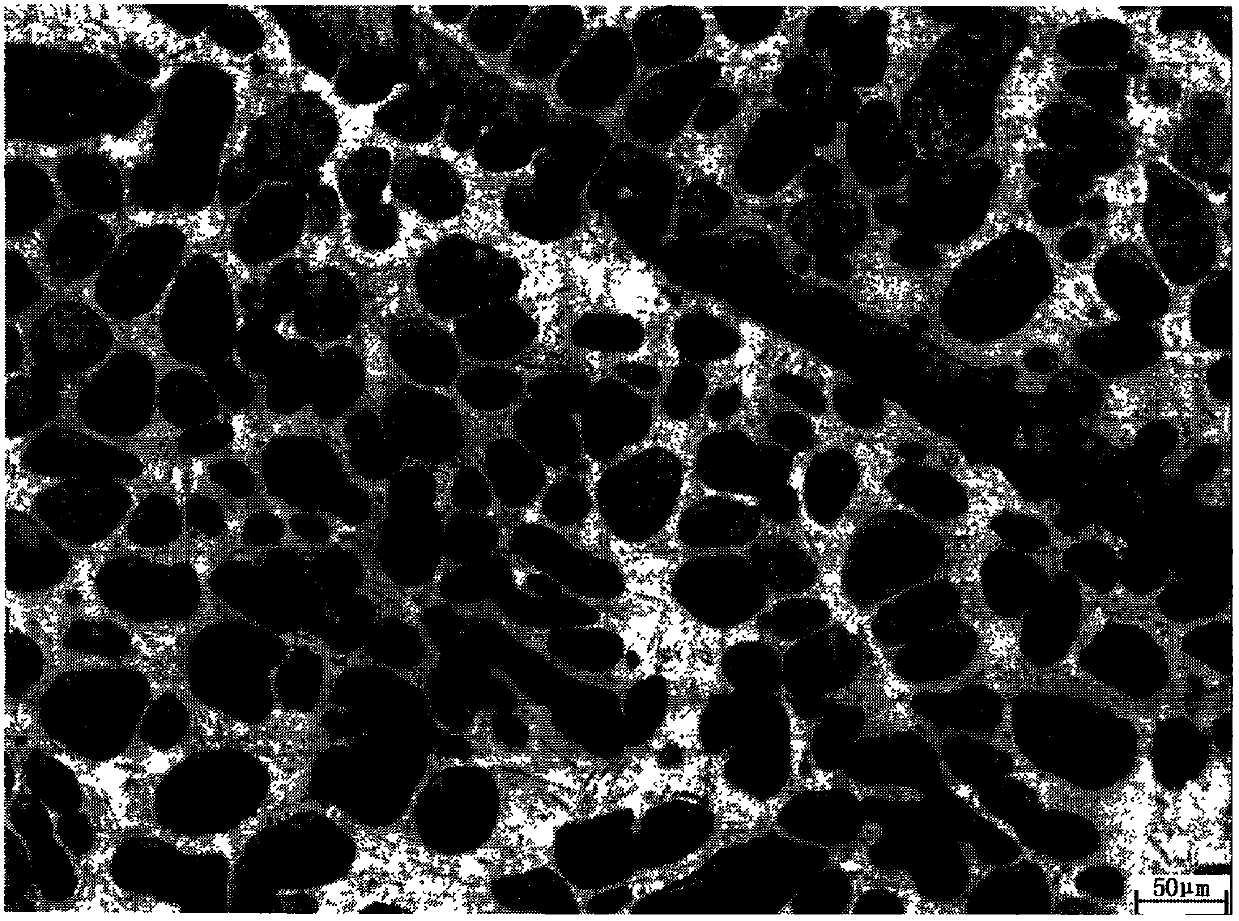

ActiveCN107267795BModerate melting temperatureImprove wettabilityEmergency protective devicesCvd grapheneMechanical property

The invention discloses a high-conductivity silver-based melt material, which is smelted from 92-101 parts by weight of silver or silver alloy, 2-12 parts by weight of silver-based graphene and 0.5-1.5 parts by weight of trace elements: firstly, accurate Weigh each raw material; use a vacuum smelting furnace to melt silver-based graphene and 35-40% silver or silver alloy into alloy material A1; then melt trace elements and the remaining silver or silver alloy into alloy material A2; finally The molten alloy material A1 is added to the molten alloy material A2 to obtain a molten silver-based alloy, and the molten silver-based alloy is processed according to a conventional method to obtain a filamentous or strip-shaped molten material. The silver-based alloy melt material containing graphene obtained by smelting in the present invention is non-toxic, harmless, green and environmentally friendly, has moderate melting temperature, good wettability, strong electrical conductivity, and excellent mechanical properties. It is used in the field of electric vacuum, It can guarantee the high cleanliness of the vacuum system and vacuum components, which broadens its application range.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A kind of high-strength silver-based solder containing graphene and its melting method

ActiveCN107309574BModerate melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaRubidiumGold alloys

The invention discloses a graphene-containing high-strength silver-based brazing filler metal. The graphene-containing high-strength silver-based brazing filler metal is prepared from, by weight, 65.0-99.5 parts of silver or silver alloy, 6.5-26.5 parts of metalized graphene, 0.5-9.6 parts of rubidium and 0.1-0.3 part of microelements in a smelting mode. A smelting method comprises the steps that the raw materials are weighed accurately in proportion; the metalized graphene and 55-70% of silver or the silver alloy are smelted through a vacuum smelting furnace to prepare a silver / graphene alloy Al, then the rubidium and 24-29% of silver or silver alloy are smelted in the vacuum smelting furnace to prepare an alloy A2, and the microelements and the rest of silver or silver alloy are smelted in the vacuum smelting furnace to prepare an alloy A3; and the alloy A2 and the alloy A3 are added in sequence after the alloy A1 is smelted, a molten silver-based alloy is obtained, and the silk-shaped or strip-shaped silver-based brazing filler material is obtained after the molten silver-based alloy is processed through a conventional method. The researched and developed graphene-containing high-strength silver-based brazing filler material does not contain poisonous or harmful elements such as Cd, Pb and Cr, and is environmentally friendly, moderate in smelting temperature, good in wettability and high in strength.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Covering agent for aluminum alloy melting

InactiveCN107779635AImprove insulation effectAvoid secondary oxidationLithium chloridePotassium fluoride

A covering agent for aluminum alloy smelting, characterized in that the covering agent is composed of the following components in parts by mass: 15-30 parts of potassium chloride, 20-30 parts of sodium chloride, 4-4 parts of potassium fluoride 6 parts, 2-6 parts of sodium bisulfate, 10-18 parts of lithium chloride, 4-6 parts of sodium fluorosilicate, 4-8 parts of aluminum trichloride, and 2-4 parts of cryolite. The covering agent configuration process of the present invention can effectively improve the heat preservation of the covering agent, prevent secondary oxidation, reduce the thickness of the sintered layer of the covering agent, have suitable melting temperature, fast melting and fast expansion speed, and form a layer of oily film on the surface of the casting. Effectively prevent castings from oxidizing, burning, and getting gas. It has strong chemical stability and thermal stability, has no corrosion effect on molten aluminum and furnace lining, and ensures the original composition and performance of the alloy.

Owner:徐州轩辕铝业有限公司

A kind of multi-component silver solder

ActiveCN103111770BReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

A kind of high-strength nickel-based solder containing boron and its melting method

ActiveCN107309573BModerate melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaRubidiumCopper

The invention discloses high-strength nickel-based brazing filler metal containing boron alkene. The high-strength nickel-based brazing filler metal containing the boron alkene is prepared from 60-160 parts of nickel, 16-29 parts of palladium, 6-15 parts of metalized boron alkene, 2.5-9.0 parts of rubidium, 2-16 parts of copper, 1-3.5 parts of carbon, 1.2-4.5 parts of chromium and 0.1-0.3 part of microelements in s smelting mode. A smelting method comprises the steps that the metalized boron alkene and 50-65% of nickel are smelted to prepare a nickel / boron alkene alloy material Al through a vacuum smelting furnace; then the chromium, palladium, copper and 25-30% of nickel are smelted in the vacuum smelting furnace to obtain an alloy A2; and the rubidium, microelements, carbon and the rest of nickel are smelted in the vacuum smelting furnace to obtain an alloy A3; and the alloy A2 and the alloy A3 are added in sequence after the alloy material A1 is smelted, a molten nickel-based alloy is obtained, and the silk-shaped or strip-shaped nickel-based brazing filler metal is obtained after the molten silver-based alloy is machined through a conventional method. The researched and developed nickel-based brazing filler metal containing boron alkene does not contain poisonous or harmful elements, and is environmentally friendly, moderate in smelting temperature, good in wettability and high in strength.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

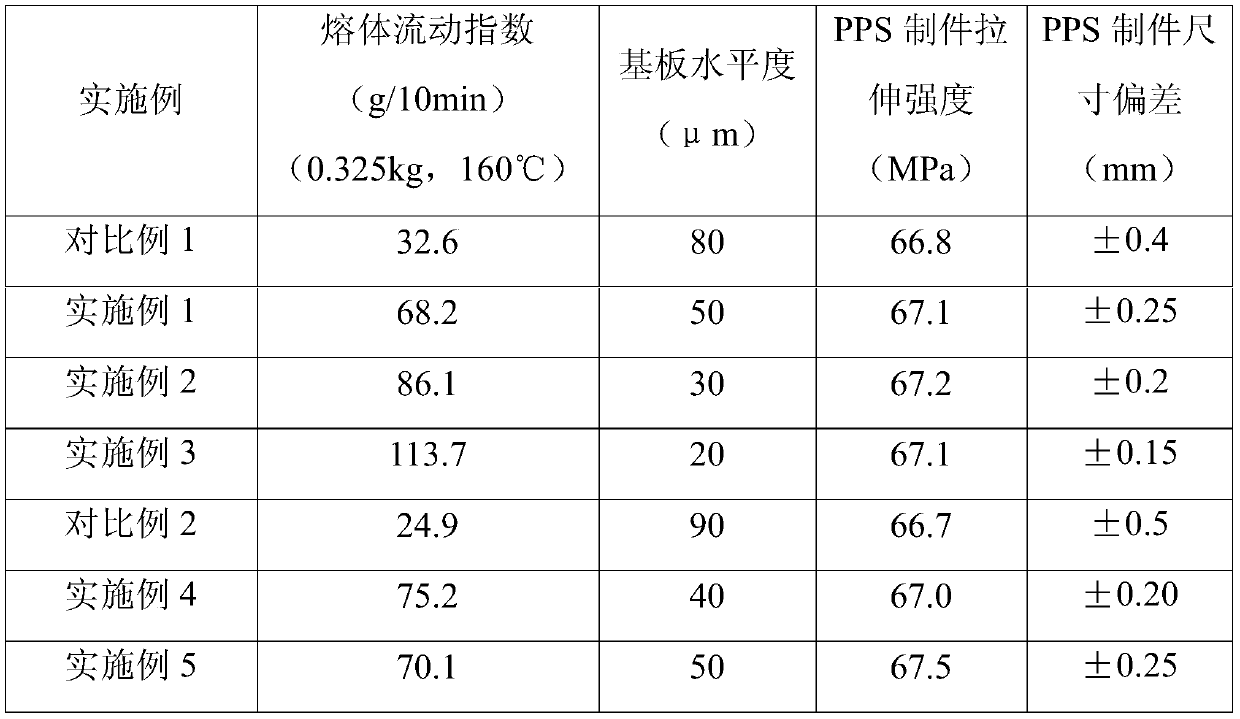

High molecular polymer powder material

ActiveCN109852231AImprove melt fluidityStrong adhesionPowdery paintsPolyamide coatingsPolymer sciencePolymer substrate

A high molecular polymer powder material is characterized by comprising the following components in percentage by mass: 80-99.8 percent of high molecular polymer substrate, 0.1-5 percent of adhesion promoting resin and 0.1-15 percent of melt flow assistant. A mechanical mix process or an extrusion blending repulverizing process is adopted to uniformly mix the high molecular polymer substrate, theadhesion promoting resin and the melt flow assistant to obtain the high molecular polymer powder material; wherein the high molecular polymer powder material has excellent melt flow, and the melt flowrate thereof is at least 20% higher than the same polymer substrate without the addition of melt flow assistant, as measured according to ASTM 1238 (2015) at 160 DEG C under a load of 0.325 kg. The invention makes use of the self-leveling property of the melted high molecular polymer powder material with good melt fluidity, realizes accurate and rapid leveling of the substrate, improves the production efficiency, reduces the cost, and improves the accuracy and surface quality of the sintered workpiece.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Brazing rare earth magnesium alloy filler metal, preparation method and brazing process

ActiveCN106077994BUniform compositionGood wetting and spreadingWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses brazing rare earth magnesium alloy brazing filler metal and a preparation method and a brazing process. The brazing rare earth magnesium alloy brazing filler metal comprises the following element components in percentage by weight: 13-19% of Zn, 1.0-3.0% of Ni, 1.8-4.4% of Al, 0.4-1.0% of Ti, 5.1-7.0% of Cu, 0.3-0.8% of Mn, 0.004-0.01% of La, 0.004-0.01% of Nd, and the balance of Mg. The magnesium alloy brazing filler metal reaches the brazing temperature of 420-460 DEG C, and is proper in melting temperature and uniform in components; and a magnesium alloy brazing filler metal foil piece facilitates acceleration of dispersion and interface reaction of all alloy elements in the brazing connecting process, so that the wetting spreadability and the gap filling performance of the brazing filler metal in a rare earth magnesium alloy are improved, the grains are refined, the residual stress is reduced, and the joint bonding strength is improved.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

A kind of preparation method of lead-free solder for high-lead high-temperature replacement

ActiveCN103223560BImprove economyEasy to getWelding/cutting media/materialsSoldering mediaChemical compositionAlternative methods

The invention discloses lead-free brazing filler metal for replacing high-lead high-temperature brazing filler metal, which is characterized in that the lead-free brazing filler metal comprises the following chemical compositions: 60-80wt% of Zn and 20-40wt% of Sn, wherein the melting temperature of the lead-free brazing filler metal is 199-390 DEG C, and the shear strength is 34-39 MPa. The melting temperature of the lead-free brazing filler metal is relatively appropriate, and the potentiality of the lead-free brazing filler metal for replacing the high-lead high-temperature brazing filler metal is great.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of preparation method of high melting point lead-free solder for electronic packaging

ActiveCN103084750BEasy to getImprove economyWelding/cutting media/materialsSoldering mediaChemical compositionCopper

The invention relates to a high-melting-point lead free brazing filler metal used for electronic packaging. The high-melting-point lead free brazing filler metal used for electronic packaging is characterized in that the chemical composition of the brazing filler metal comprises, by weight, 88% to 89.5% of bismuth (Bi), 10% of silver (Ag) and 0.5% to 2% of copper(Cu). The melting temperature of the brazing filler metal is 260 DEG C to 270 DEG C. The shearing strength of the brazing filler metal is from 28 Mpa to 29.5 Mpa. Due to the fact that the brazing filler metal has an appropriate metlting temperature, the high-melting-point lead free brazing filler metal used for electronic packaging is large in potential to be a substituted brazing filler metal for a high-lead brazing filler metal.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Brazing filler metal for brazing ZrB2-SiC ultrahigh-temperature ceramic and process for brazing by using brazing filler metal

ActiveCN106112310AModerate meltingModerate melting temperatureWelding/cutting media/materialsSoldering mediaFiller metalPollution

The invention discloses brazing filler metal for brazing ZrB2-SiC ultrahigh-temperature ceramic and a process for brazing by using the brazing filler metal. The brazing filler metal comprises Cu, Ti, Zr, Ni and Co. The brazing process comprises the following steps: various raw materials are mixed to manufacture a brazing material to assemble on the ZrB2-SiC ultrahigh-temperature ceramic to form a welding sample; and the welding sample is positioned in vacuum brazing equipment, is heated to reach 910-1000 DEG C by a heating-insulation-heating-insulation mode, and is cooled to reach the room temperature. The brazing filler metal is proper in melting temperature and uniform in melting; and meanwhile, the vacuum brazing process is adopted, so that parent metal is located in a vacuum state in the heating process without the deformation and grain thickening phenomenon and without generating such problems as oxidation and pollution, the operation is stable and reliable, the surface wetting spreadability is better, the brazing gap filling is facilitated, the joint comprehensive performance is improved, and a brazing joint with excellent performance can be obtained.

Owner:JIANGSU UNIV OF SCI & TECH

Low-silver copper-based solder free of spillover phenomenon during weld period

ActiveCN103008915BRight melting pointEasy to processWelding/cutting media/materialsSoldering mediaIndiumRare earth

The invention discloses a low-silver copper-based solder free of a spillover phenomenon during a weld period. Aiming at the defect that the spillover phenomenon of the solder often occurs when brazing is performed by using traditional low-silver copper-based solder, the invention aims to provide the low-silver copper-based solder which is controllable in flowability and is free of the spillover phenomenon of the traditional low-silver copper-based solder during a process of welding copper and copper alloy. The low-silver copper-based solder disclosed by the invention is realized through the following technical scheme: the low-silver copper-based solder free of the spillover phenomenon during the weld period comprises the following components in weight percent: 6.6-7.8 percent of phosphorus (P), 0.5-2.2 percent of silver (Ag), 0.01-0.4 percent of indium (In), 0.001-0.2 percent of silicon (Si), 0.001-0.1 percent of rare earth and the balance copper (Cu).

Owner:浙江信和科技股份有限公司

A kind of sn-zn-ag-ni alloy lead-free solder and preparation method thereof

ActiveCN104002058BModerate melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaSolderingWeld line

Disclosed are a Sn-Zn-Ag-Ni alloy lead-free solder and a preparation method thereof. The Sn-Zn-Ag-Ni alloy lead-free solder is mainly applied to low-temperature soldering of pure aluminum and aluminum alloy. The Sn-Zn-Ag-Ni alloy lead-free solder is composed of, by weight percentage, 8.0-10.0% of Zn, 0.5-1.5% of Ag, 0.5-1.2% of Ni and Sn as balance. The Sn-Zn-Ag-Ni alloy lead-free solder is low in melting temperature, good in soldering technological property and high in lubricity, achieves a welding deposition rate higher than 75% and a welding line tensile strength sigma b higher than or equal to 50 MPa, and is applicable to low-temperature soldering of the pure aluminum and various aluminum alloys such as 3A21, 6063 and 6061.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com