A kind of sn-zn-ag-ni alloy lead-free solder and preparation method thereof

A lead-free solder and alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as poor corrosion resistance of joints, and achieve mass production, good wettability, and good brazing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Sn-Zn-Ag-Ni alloy solder (Zn8.0wt%, Ag0.7wt%, Ni1.2wt%, Sn surplus)

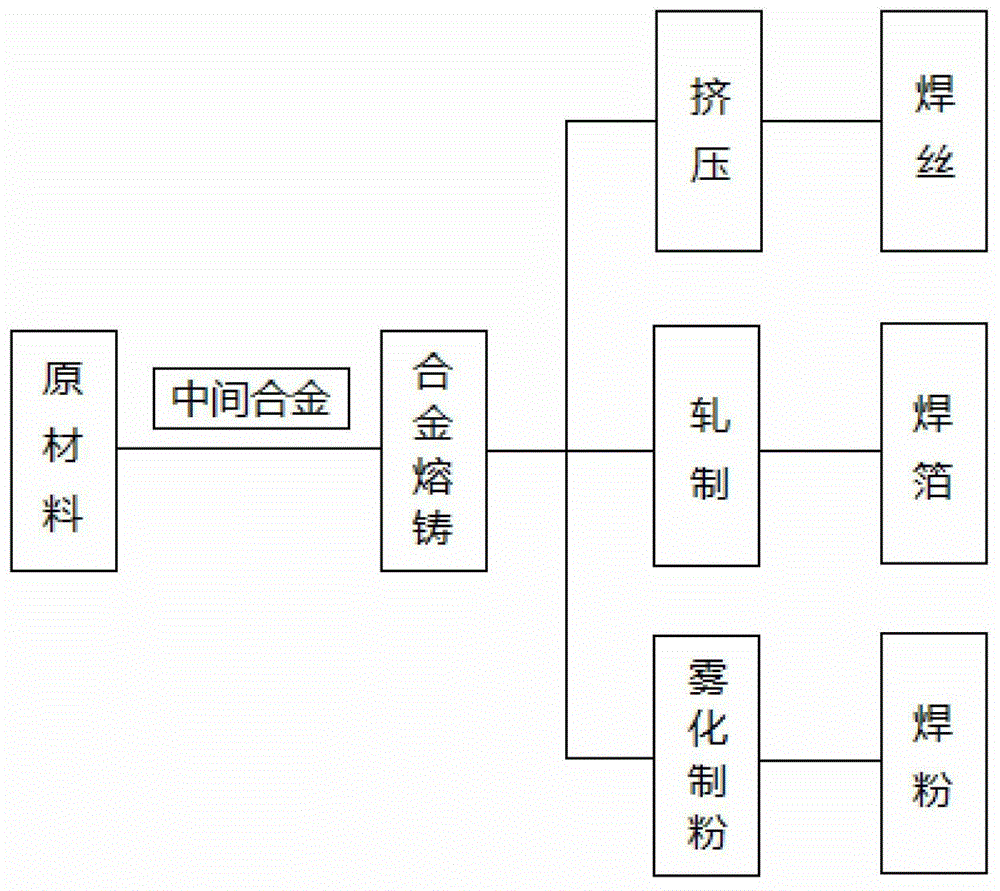

[0033] Preparation steps such as figure 1 shown.

[0034] Step 1: Weighing the metal raw material

[0035] By weight percentage, take 80 grams of Zn, 7 grams of Ag, 12 grams of Ni and 901 grams of Sn respectively;

[0036] Step 2: Master alloy melting and casting

[0037] Then weigh 120 grams of Sn, place 12 grams of Ni metal raw materials in a graphite crucible, use an intermediate frequency induction furnace, heat to 600 ° C for melting, and cast to form a SnNi master alloy;

[0039] Using an intermediate frequency induction furnace, melt and cast the remaining Sn, Zn, Ag metal raw materials and SnNi master alloy at 250°C to 300°C to make a rod-shaped Sn-Zn-Ag-Ni alloy ingot with a diameter of 30mm;

[0040] Step 4: Wire Preparation

[0041] The casted alloy rod-shaped ingot is extruded by an extruder to make a welding wire with a diameter of 1 mm. ...

Embodiment 2

[0042] Embodiment 2: Sn-Zn-Ag-Ni alloy solder (Zn8.5wt%, Ag0.8wt%, Ni1.1wt%, Sn surplus)

[0043] Step 1: Weighing the metal raw material

[0044] By weight percentage, take 85 grams of Zn, 8 grams of Ag, 11 grams of Ni and 896 grams of Sn respectively;

[0045] Step 2: Master alloy melting and casting

[0046] Then weigh 110 grams of Sn, place 11 grams of Ni metal raw materials in a graphite crucible, use an intermediate frequency induction furnace, heat to 600 ° C for melting, and cast to form a SnNi master alloy;

[0048] Using an intermediate frequency induction furnace, melt and cast the remaining Sn, Zn, Ag metal raw materials and SnNi master alloy at 250°C to 300°C to make a plate-shaped Sn-Zn-Ag-Ni alloy ingot with a thickness of 5mm;

[0049] Step 4: Solder Foil Preparation

[0050] The alloy plate-shaped ingot after melting and casting is rolled by a rolling mill to make a welding foil with a thickness of 0.1mm.

Embodiment 3

[0051] Embodiment 3: Sn-Zn-Ag-Ni alloy solder (Zn9.0wt%, Ag1.0wt%, Ni1.0wt%, Sn surplus)

[0052] Step 1: Weighing the metal raw material

[0053] By weight percentage, take 90 grams of Zn, 10 grams of Ag, 10 grams of Ni and 890 grams of Sn respectively;

[0054] Step 2: Master alloy melting and casting

[0055] Then weigh 100 grams of Sn, place 10 grams of Ni metal raw materials in a graphite crucible, use an intermediate frequency induction furnace, heat to 600 ° C for melting, and cast to form a SnNi master alloy;

[0057] Using an intermediate frequency induction furnace, melt and cast the remaining Sn, Zn, Ag metal raw materials and SnNi master alloy at 250°C to 300°C to make a rod-shaped Sn-Zn-Ag-Ni alloy ingot with a diameter of 30mm;

[0058] Step 4: Solder Powder Preparation

[0059] Using the gas atomization powder making method, using nitrogen as the atomizing gas, place the rod-shaped alloy ingot prepared in step 3 under the conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com