A kind of preparation method of lead-free solder for high-lead high-temperature replacement

A technology of solder and high temperature, which is applied in the field of lead-free solder for high-lead and high-temperature replacement and its preparation, can solve problems that have not been paid attention to, and achieve the effects of good economy, easy raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

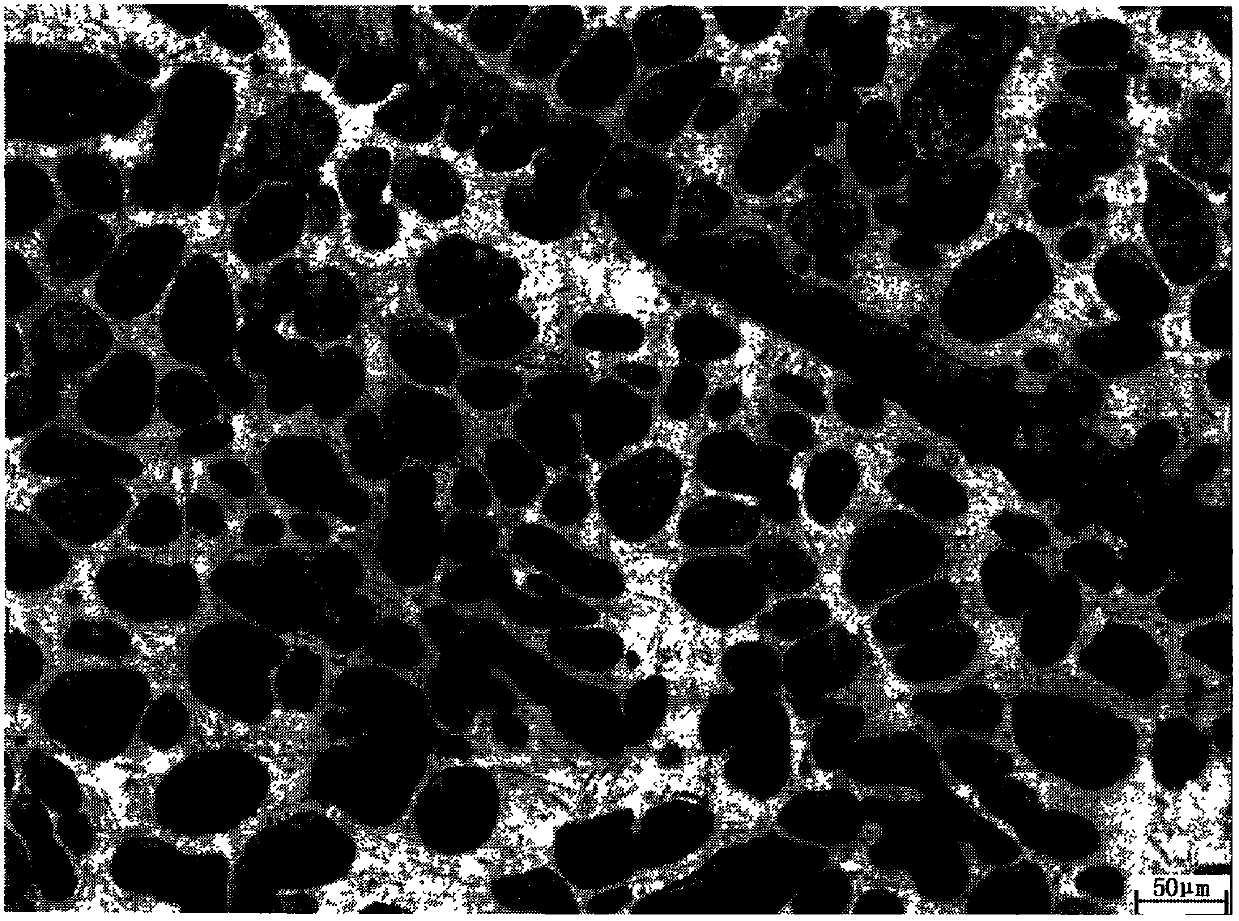

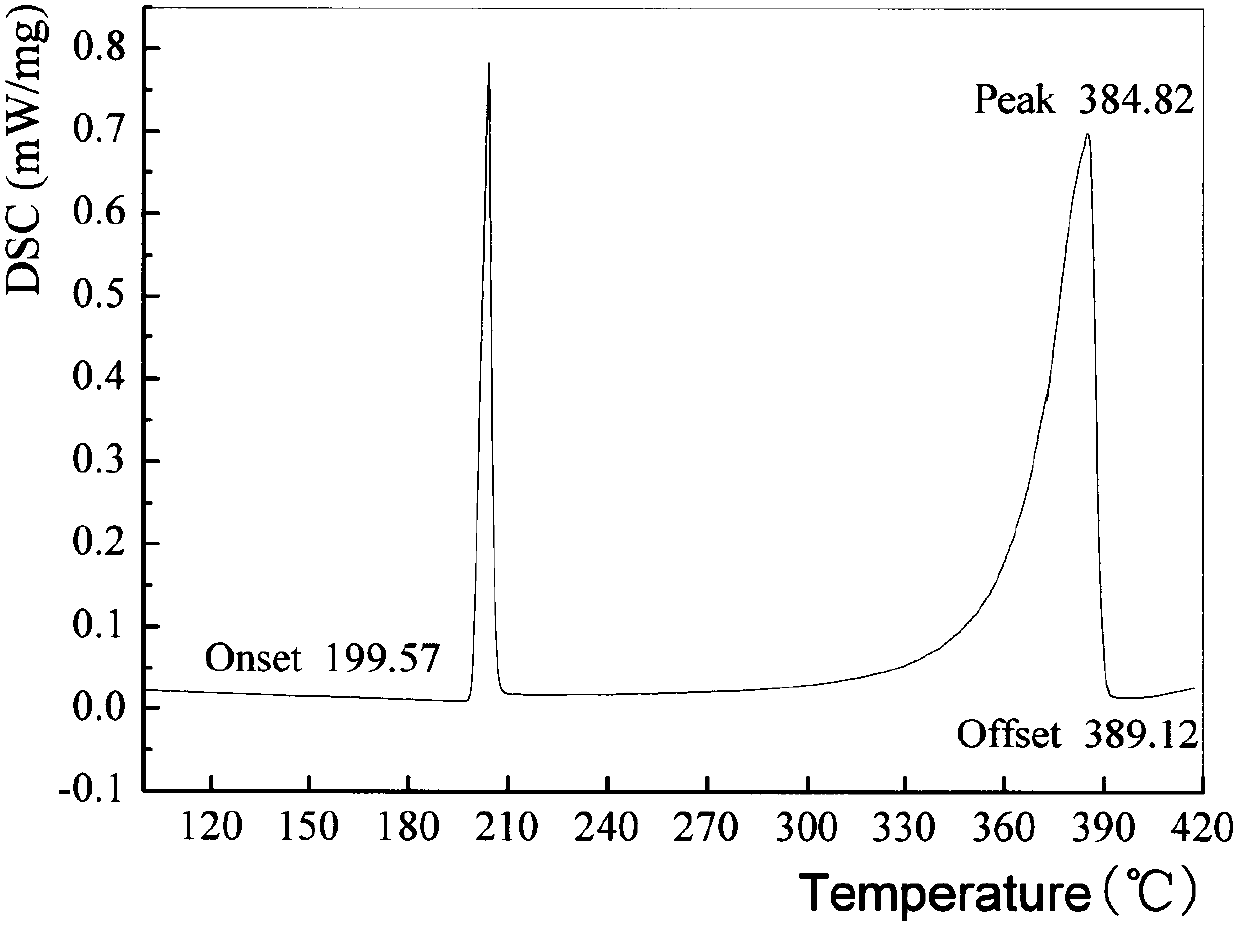

[0049] A lead-free solder for high-lead high temperature replacement, the chemical composition of the solder is: 80wt% Zn, 20wt% Sn, hereinafter referred to as 80Zn-20Sn, figure 1 It is the metallographic structure diagram of embodiment 1.

Embodiment 2

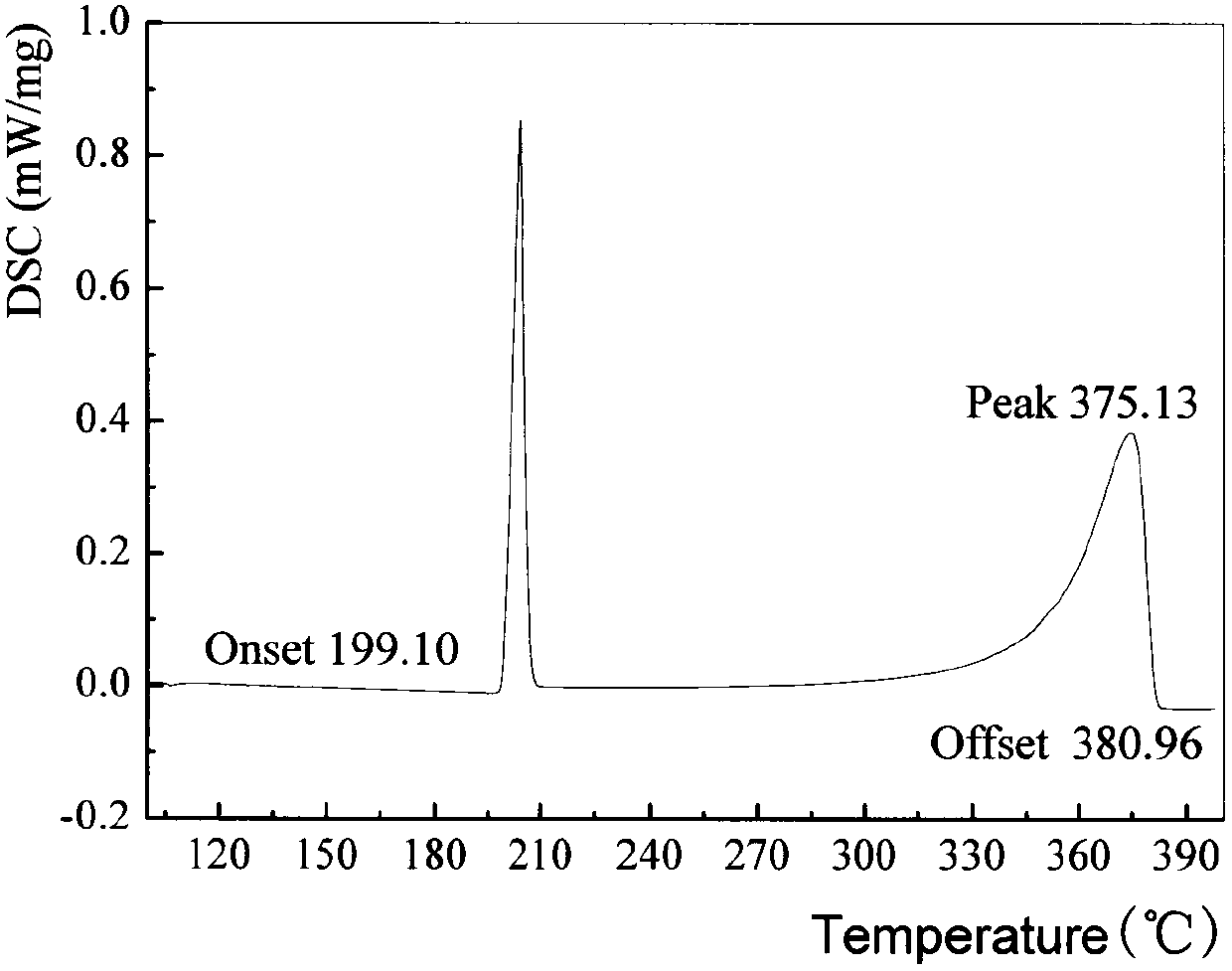

[0051] A lead-free solder for high-lead high temperature replacement, the chemical composition of the solder is: 70wt% Zn, 30wt% Sn, hereinafter referred to as 70Zn-30Sn, figure 2 It is the metallographic structure diagram of embodiment 2.

Embodiment 3

[0053] A lead-free solder for high-lead high-temperature replacement, the chemical composition of the solder is: 60wt% Zn, 40wt% Sn, hereinafter referred to as 60Zn-40Sn, image 3 It is the metallographic structure diagram of embodiment 3.

[0054] from Figure 1-3 It can be seen that the microstructures of 80Zn-20Sn, 70Zn-30Sn and 60Zn-40Sn are all composed of primary crystal Zn phase, eutectic SnZn phase and Sn phase, all of which are coarse dendritic and fine eutectic SnZn particles scattered in bright The white Sn phase is on. With the increase of Zn content, the number of primary crystal Zn phases increases, and the shape becomes coarser, changing from block to lath. It is due to the increase of the primary crystal Zn phase that the liquid phase composition of the solder at 250 ° C also decreases with the decrease of the Sn content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com