A kind of preparation method of high melting point lead-free solder for electronic packaging

A lead-free solder, electronic packaging technology, used in manufacturing tools, welding equipment, metal processing equipment and other directions, can solve the problem of under-recognized, achieve the advantages of mechanical properties, easy to obtain, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

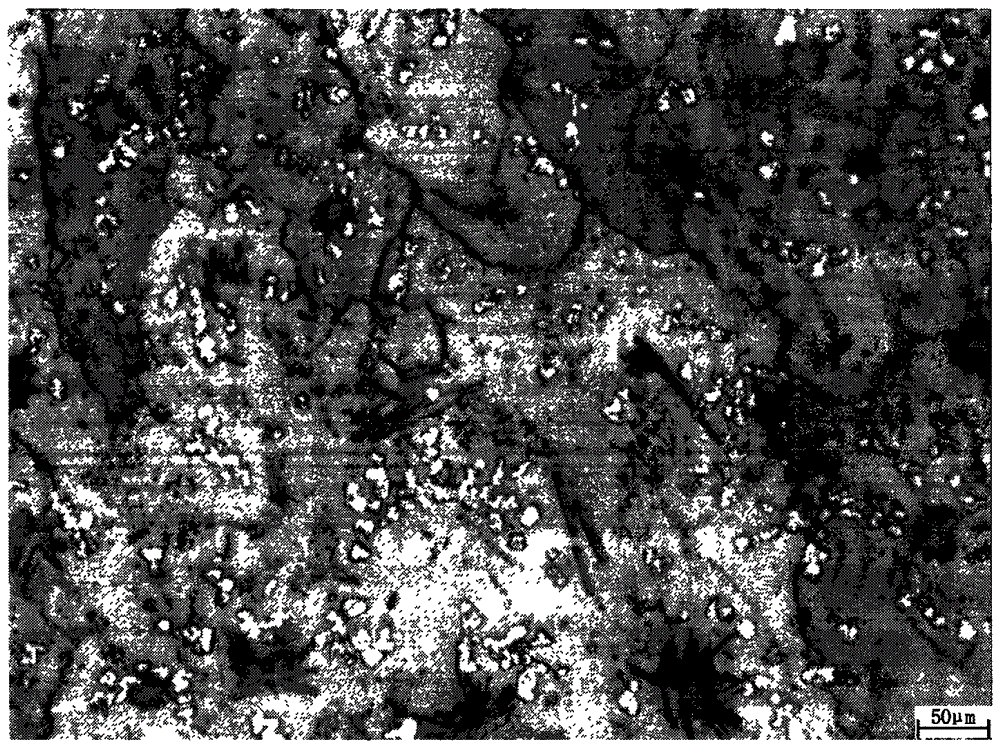

[0043] A high melting point lead-free solder for electronic packaging, the chemical composition of the solder is: 88wt% Bi, 10wt% Ag, 2wt% Cu, figure 1 It is the metallographic structure diagram of embodiment 1.

Embodiment 2

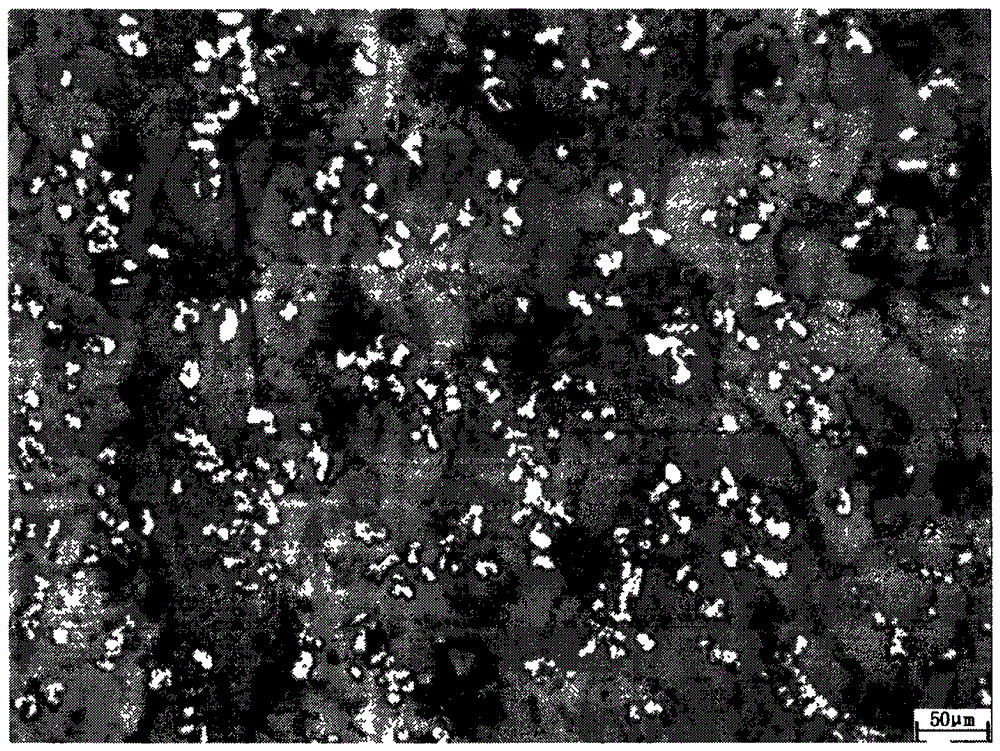

[0045] A high melting point lead-free solder for electronic packaging, the chemical composition of the solder is: 89wt% Bi, 10wt% Ag, 1wt% Cu, figure 2 It is the metallographic structure diagram of embodiment 2.

Embodiment 3

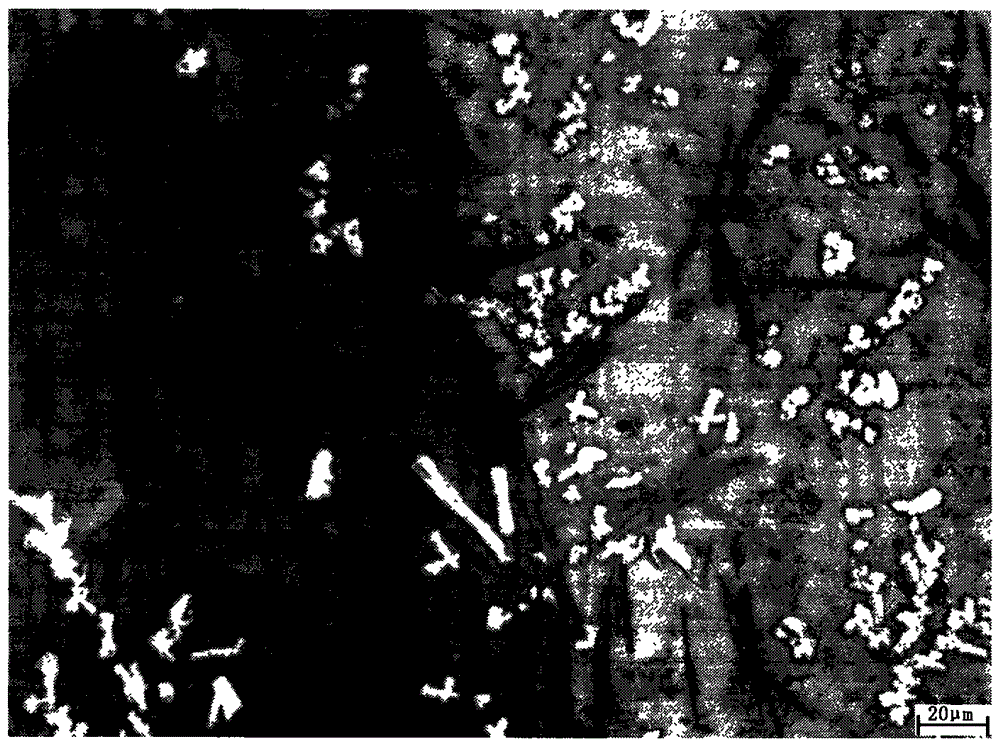

[0047] A high melting point lead-free solder for electronic packaging, the chemical composition of the solder is: 89.5wt% Bi, 10wt% Ag, 0.5wt% Cu, image 3 It is the metallographic structure diagram of embodiment 3.

[0048] From Figure 1-3 It can be seen that the microstructure of Bi-10Ag-0.5Cu, Bi-10Ag-1Cu, Bi-10Ag-2Cu solder consists of Bi phase, Bi-Ag eutectic structure, bright white dendritic primary crystal Ag and lath-like Cu phase composition. After adding a small amount of Cu, the biggest change in the microstructure of Bi-Ag-Cu and Bi-Ag is the formation of lath-like Cu phases in the structure, which are dispersed in the alloy system, and a small part sometimes gathers into a scallop shape. The morphology of the hypereutectic structure has a great influence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com