A brazing material used for Zrb2-sic ultra-high temperature ceramic brazing and a brazing process using the brazing material

A technology of ultra-high temperature ceramics and zrb2-sic, which is applied in the direction of welding/cutting media/materials, welding media, manufacturing tools, etc., can solve the problems of non-dense interface bonding, poor wettability, and poor mechanical properties, and achieve Good surface wetting and spreading, improving mechanical properties, improving wetting and spreading ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

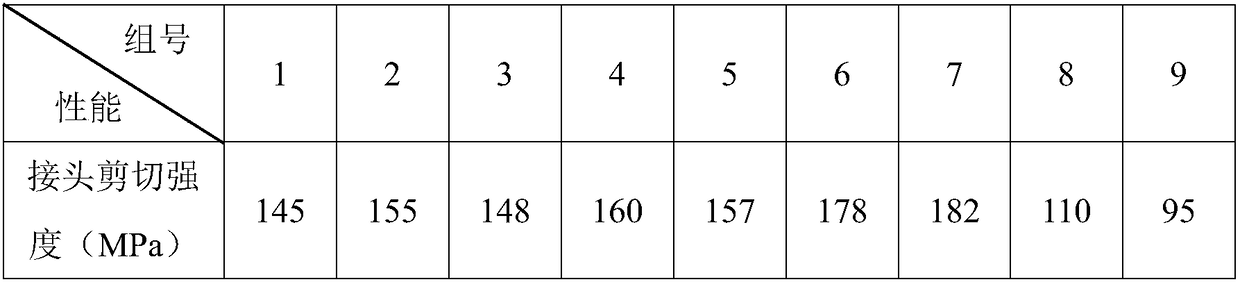

Examples

Embodiment 1

[0014] ZrB of the present invention 2 -SiC ultra-high temperature ceramic samples are all 3mm×3mm×17mm in size, and the surface to be brazed is 3mm×17mm in section.

[0015] The composition and content of the solder: Cu 39.4%, Ti 24.3%, Zr 27.8%, Ni 6.0% and Co 2.5%, and the thickness of the solder is 80 μm.

[0016] The preparation method of this solder comprises the steps:

[0017] 1) Take and mix five kinds of raw materials, 39.4g of Cu particles, 24.3g of Ti particles, 27.8g of Zr particles, 6.0g of Ni particles, and 2.5g of Co particles with a purity higher than 99.99% by weight percentage, wherein Cu particles, Ti particles , Zr particles, Ni particles, and Co particles have a particle size of 2-5 mm, mix them and pour them into a container filled with acetone, and put the container in an ultrasonic cleaner at room temperature for 12 minutes;

[0018] 2) Pour out the acetone waste liquid after cleaning, then put the mixture into an oven at 40°C for drying to obtain a d...

Embodiment 2

[0031] ZrB used in the present invention 2 -SiC ultra-high temperature ceramic samples are all 3mm×3mm×17mm in size, and the surface to be brazed is 3mm×17mm in section.

[0032] The composition and content of solder: Cu 38.8%, Ti 24.6%, Zr 27.8%, Ni 6.2%, Co 2.6%.

[0033] The preparation method of the solder is the same as that in Example 1, and the thickness of the prepared solder foil strip is 80 μm.

[0034] The technique of brazing by brazing filler metal of the present invention may further comprise the steps:

[0035] (1) Preparation stage: ZrB to be brazed 2 -Clean the surface of SiC ultra-high temperature ceramic samples to remove impurities, oil stains and oxide films on the surface, use W28~W7 metallographic sandpaper to grind and smooth, and use a polishing cloth to polish, and then ZrB 2 - SiC ultra-high temperature ceramics and brazing foil are placed in acetone, ultrasonically cleaned for 15 minutes, and dried;

[0036] (2) Assembly stage: use 502 instant a...

Embodiment 3

[0040] ZrB used in the present invention 2 -SiC ultra-high temperature ceramic samples are all 3mm×3mm×17mm in size, and the surface to be brazed is 3mm×17mm in section.

[0041] The composition and content of solder: Cu 38.9%, Ti 24.3%, Zr 28.1%, Ni 6.2%, Co 2.5%. The preparation method of the solder is the same as that in Example 1, and the thickness of the prepared solder foil strip is 80 μm.

[0042] The technique of brazing by brazing filler metal of the present invention may further comprise the steps:

[0043] (1) Preparation stage: ZrB to be brazed 2 -Clean the surface of SiC ultra-high temperature ceramic samples to remove impurities, oil stains and oxide films on the surface, use W28~W7 metallographic sandpaper to grind and smooth, and use a polishing cloth to polish, and then ZrB 2 - SiC ultra-high temperature ceramics and brazing foil are placed in acetone, ultrasonically cleaned for 15 minutes, and dried;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com