A process for brazing SIC-based composite materials using brazing materials

A brazing material and composite material technology, applied in welding/cutting media/materials, welding media, manufacturing tools, etc., can solve the problem that the working temperature of the joint cannot exceed 500 ℃, and achieve stable and reliable brazing process and stable and reliable connection Joints, effect of stabilizing high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

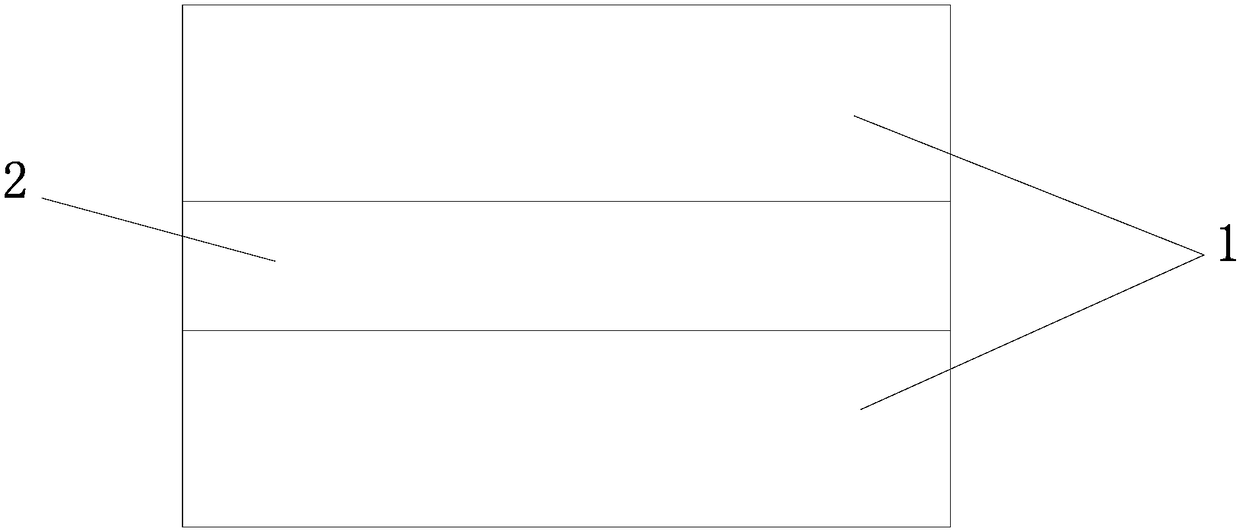

Image

Examples

Embodiment 1

[0018] The sample size of the SiC-based composite material of the present invention is 3mm×4mm×20mm, and the surface to be brazed is 3mm×4mm in section.

[0019] The composition and content of the solder: Co40.5%, Ni 11.5%, Nb26.7%, V21.3%, and the thickness of the solder is 100 μm.

[0020] The preparation method of this solder comprises the steps:

[0021] 1) Weigh high-purity Co, Ni, Nb, V powders (80-100 mesh) in proportion, and mechanically stir until homogenized;

[0022] 2) Weighing 80g of mixed powder and putting it into an electric arc furnace for smelting, cutting the alloy ingots after repeated smelting into small pieces, and putting them into the quartz tube of a high-vacuum single-roll belt throwing machine;

[0023] 3) The quartz glass tube is clamped in the electric induction heating ring of the stripping machine, and the distance between the nozzle and the surface of the copper roller is adjusted to 150 μm;

[0024] 4) Close the furnace door, and use a mechan...

Embodiment 2

[0033] The sample size of the SiC-based composite material used in the present invention is 3mm×4mm×20mm, and the surface to be brazed is 3mm×4mm in section.

[0034] The composition and content of solder: Co41.2%, Ni 10.8%, Nb26.5%, V21.5%.

[0035] The preparation method of the solder is the same as that in Example 1, and the thickness of the prepared solder foil strip is 80 μm.

[0036] The technique of brazing by brazing filler metal of the present invention may further comprise the steps:

[0037] (1) Preparation stage: Clean the surface of the SiC-based composite material sample to be brazed to remove impurities, oil stains and oxide films on the surface, use W28~W7 metallographic sandpaper to grind and smooth, and use a polishing cloth to polish, Then put the SiC-based composite material and the amorphous solder foil together in acetone, use ultrasonic cleaning for 10 minutes, and perform drying treatment;

[0038] (2) Assembly stage: use 502 instant adhesive to assem...

Embodiment 3

[0042] The sample size of the SiC-based composite material used in the present invention is 3mm×4mm×20mm, and the surface to be brazed is 3mm×4mm in section.

[0043] The composition and content of solder: Co39%, Ni 12.1%, Nb27%, V21.9%.

[0044] The preparation method of the solder is the same as that in Example 1, and the thickness of the prepared solder foil strip is 80 μm.

[0045] The technique of brazing by brazing filler metal of the present invention may further comprise the steps:

[0046] (1) Preparation stage: Clean the surface of the SiC-based composite material sample to be brazed to remove impurities, oil stains and oxide films on the surface, use W28~W7 metallographic sandpaper to grind and smooth, and use a polishing cloth to polish, Then put the SiC-based composite material and the amorphous solder foil together in acetone, use ultrasonic cleaning for 10 minutes, and perform drying treatment;

[0047] (2) Assembly stage: use 502 instant adhesive to assemble th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com