Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

A glass-ceramic, lithium-aluminum-silicon technology, used in glass tempering, glass manufacturing equipment, telephone communication, etc. Effect of Surface Stress Layer Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

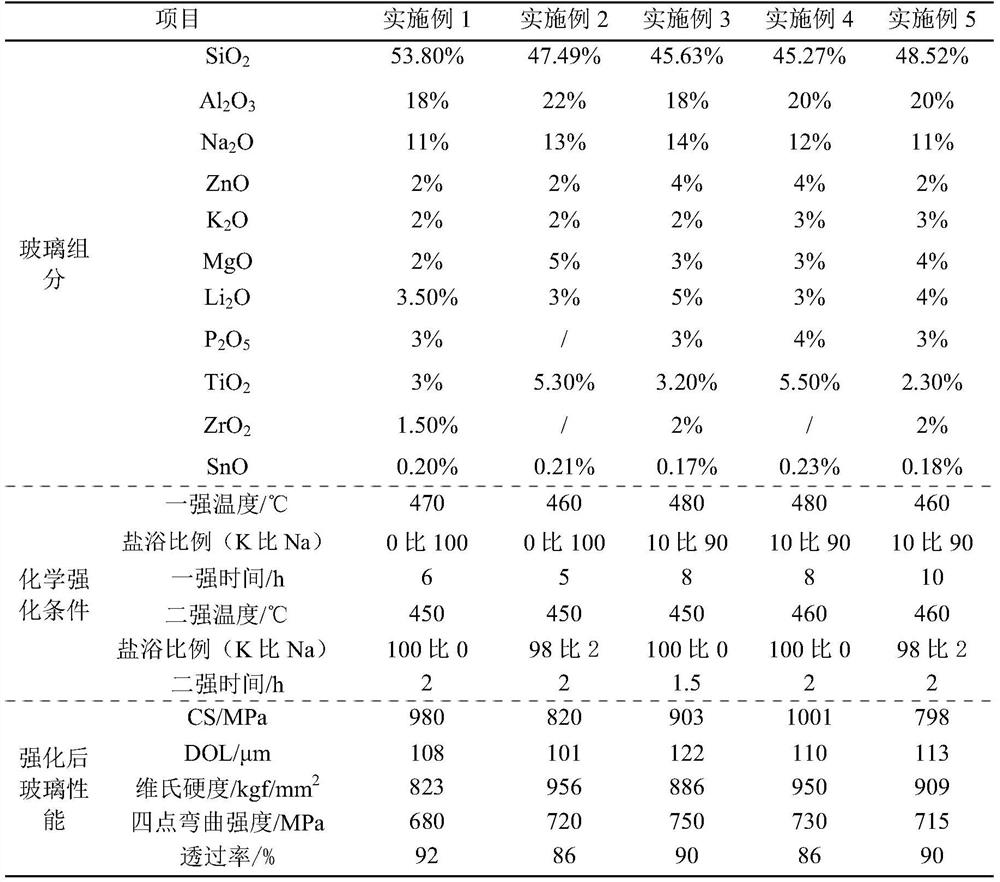

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0026] Generally speaking, strengthening the glass-ceramics by chemical ion exchange can further increase its strength. At present, the strengthening of glass-ceramics is mainly a one-step ion exchange method. To obtain a larger compression depth of the stress layer, it is necessary to prolong the ion exchange process. Time or increase the exchange temperature, but too high exchange temperature and longer exchange time will lead to stress relaxation and reduce the surface compressive stress. To obtain higher surface compressive stress, it is necessary to reduce the temperature of ion exchange, but this will lead to a smaller compression depth of the stress layer, so that the surface compressive stress of ion exchange and the compression depth of the stress layer cannot be balanced.

[0027] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com