A kind of highly conductive silver-based melt material and its melting method

A high-conductivity, silver-based technology, which is applied in the smelting of the high-conductivity silver-based melt material and the field of the high-conductivity silver-based melt material, can solve problems such as toxicity, and achieve a widened application range, strong conductivity, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

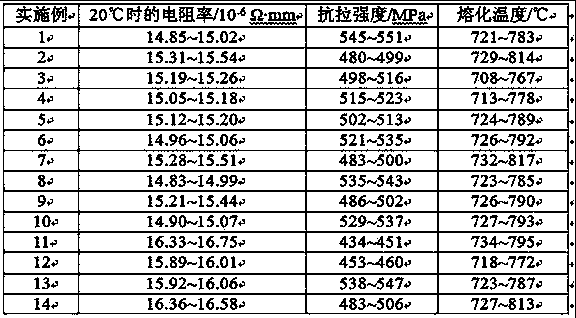

Examples

Embodiment 1

[0022] The highly conductive silver-based melt material of the present invention is formed by melting 92 kg of silver, 12 kg of silver-based graphene, 0.2 kg of rubidium, and 0.3 kg of indium:

[0023] First, 12 kg of silver-based graphene and 34.5 kg of silver were smelted into alloy material A1 in a vacuum smelting furnace; then 0.2 kg of rubidium, 0.3 kg of indium and the remaining 57.5 kg of silver were smelted into alloy material A2; finally, the melted alloy The material A1 is added to the molten alloy material A2 to obtain a molten silver-based alloy, and the molten silver-based alloy is cast or horizontally continuous casted, extruded, and drawn to obtain a highly conductive filamentous silver-based melt alloy, The melt alloy has high electrical conductivity (it is stronger than that of pure silver, and when pure silver is 20°C, the resistivity is the lowest 15.62×10 -6 Ω mm), moderate melting temperature and excellent mechanical properties, its technical indicators a...

Embodiment 2

[0025] The highly conductive silver-based melt material of the present invention is formed by melting 101 kg of silver, 2 kg of silver-based graphene, 0.3 kg of rubidium, and 0.2 kg of yttrium:

[0026] First, 2 kg of silver-based graphene and 37.8 kg of silver were smelted into alloy material A1 in a vacuum smelting furnace; then 0.3 kg of rubidium, 0.2 kg of yttrium and the remaining 63.2 kg of silver were smelted into alloy material A2; finally, the molten alloy Material A1 is added to the molten alloy material A2 to obtain a molten silver-based alloy, and the molten silver-based alloy is cast into an ingot, and the ingot is first extruded into a strip, and after rough rolling and finish rolling, a high conductivity A strip-shaped silver-based melt alloy with high electrical conductivity (stronger than that of pure silver. When pure silver is at 20°C, the resistivity is the lowest 15.62×10 -6 Ω mm), moderate melting temperature and excellent mechanical properties, its tech...

Embodiment 3

[0028] The highly conductive silver-based melt material of the present invention is formed by melting 92 kg of silver, 2 kg of silver-based graphene, 0.5 kg of indium, and 1.0 kg of yttrium by melting the method in Example 1, and the melt alloy has higher conductivity Sex (stronger than the conductivity of pure silver), moderate melting temperature and excellent mechanical properties, its technical indicators are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com