A kind of high-strength silver-based solder containing graphene and its melting method

A technology of silver-based solder and graphene, which is applied in the field of melting of high-strength silver-based solder and high-strength silver-based solder, and can solve problems such as low mechanical strength, low connection strength, and poor connection performance of silver solder paste , to achieve the effects of improving fluidity and wettability, moderate melting temperature, and lowering melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

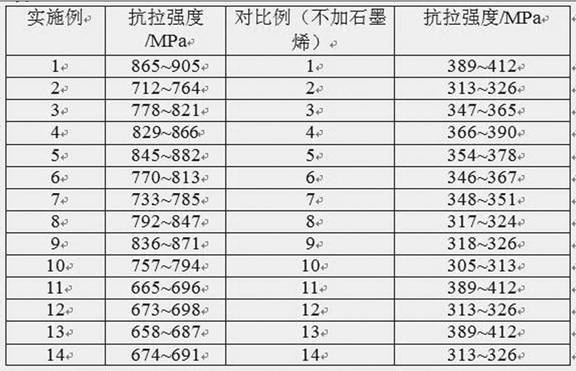

Embodiment 1

[0024] The high-strength silver-based solder containing graphene of the present invention is formed by smelting 65.0kg of silver, 26.5kg of silver-coated graphene, 9.6kg of rubidium, 0.3kg of magnesium and 0.3kg of praseodymium:

[0025] Firstly, silver-plated graphene and 39kg of silver were smelted into silver / graphene alloy A1 in a vacuum smelting furnace; secondly, rubidium and 16.9kg of silver were smelted into A2 alloy in a vacuum smelting furnace, and then trace elements were mixed with the remaining 9.1kg Silver is smelted into A3 alloy in a vacuum smelting furnace; after melting A1 alloy, add A2 alloy and A3 alloy in turn to obtain molten silver-based alloy, and cast or horizontal continuous casting, extrusion, and drawing of molten silver-based alloy , to obtain the desired silver-based solder wire. The silver-based solder wire prepared by the present invention has a moderate melting temperature and excellent mechanical properties, and the specific technical indicato...

Embodiment 2

[0027] The high-strength silver-based solder containing graphene of the present invention is formed by melting 99.5kg of silver, 6.5kg of silver-coated graphene, 0.5kg of rubidium, 0.1kg of magnesium, and 0.1kg of yttrium:

[0028] Firstly, silver-coated graphene and 60kg of silver are smelted into silver / graphene alloy A1 in a vacuum smelting furnace; secondly, rubidium and 26kg of silver are smelted into A2 alloy in a vacuum smelting furnace, and then trace elements are mixed with the remaining 13.5kg of silver A3 alloy is smelted in a vacuum smelting furnace; A2 alloy and A3 alloy are added in sequence after melting A1 alloy to obtain a molten silver-based alloy, which is cast into an ingot, and the ingot is first extruded into a strip After rough rolling and finish rolling, it can be prepared into silver-based solder strip (or foil). The silver-based solder ribbon prepared by the present invention has a moderate melting temperature and excellent mechanical properties, and ...

Embodiment 3

[0030] The present invention contains the high-strength silver-based solder of graphene, is by the silver of 82.2kg, the silver-plated graphene of 16.5kg, the rubidium of 5.10kg, the magnesium of 0.2kg, the germanium of 0.2kg is smelted by the method for embodiment 1 and forms become. The silver-based solder ribbon prepared by the present invention has a moderate melting temperature and excellent mechanical properties, and the specific technical indicators are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com