Low-silver copper-based solder free of spillover phenomenon during weld period

A solder, silver-copper technology, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as solder overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Manufacture of brazing filler metal: it is manufactured by general-purpose copper-based brazing filler metal induction melting, extrusion, drawing and ring making processes.

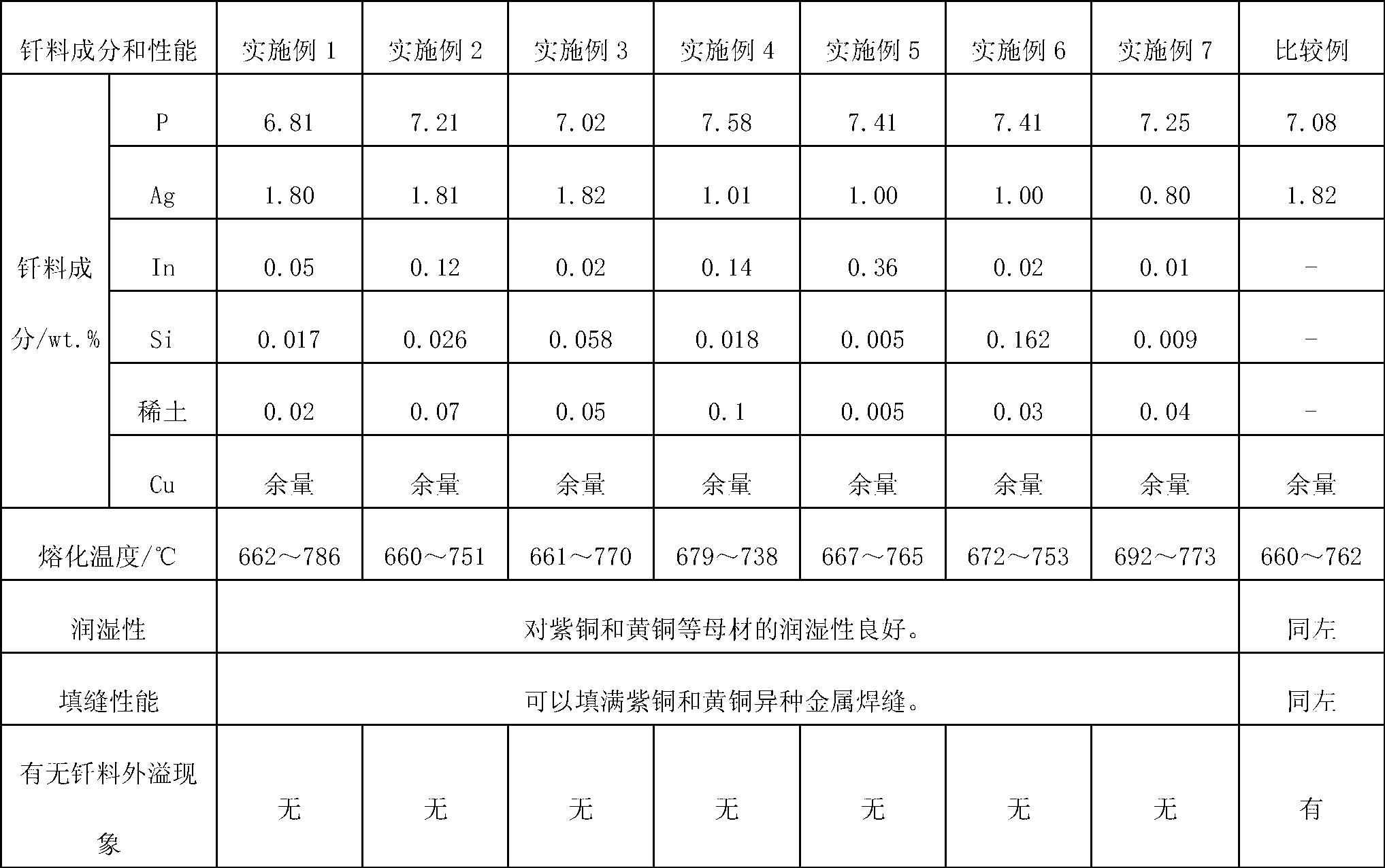

[0023] The embodiment of brazing filler metal of the present invention and the performance comparison with existing low-silver copper base brazing filler metal are shown in Table 1. The melting temperature of the solder was measured by a differential thermal analyzer, the heating rate was 15°C / min, and the protective gas was N2. The wettability test of the solder is carried out in a muffle furnace, with 102 flux, and the test temperature is 800±10°C. The seam filling test of the solder is carried out by flame brazing with 102 flux.

[0024] Table 1: The embodiment of brazing filler metal of the present invention and the performance comparison with existing low-silver copper base brazing filler metal

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com