Pull curtain type full-closed overflowing-free spray gun mouth for electrostatic powder spraying booth

A powder spraying room, fully enclosed technology, applied in the direction of spraying room, spraying device, device for coating liquid on the surface, etc., can solve the problems of powder overflow, increase system power consumption, etc., to save floor space and reduce energy consumption , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

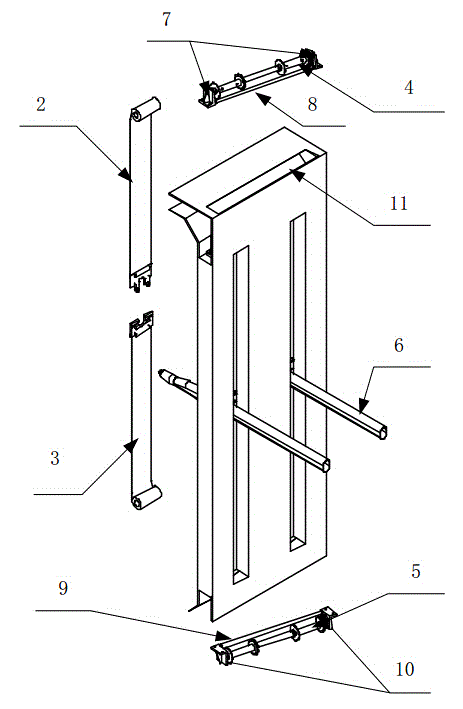

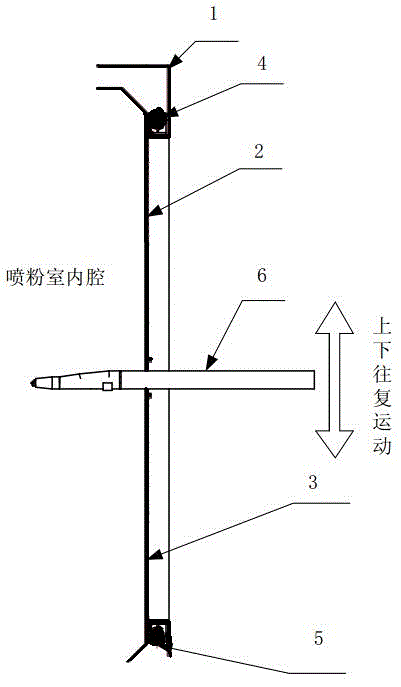

[0016] Such as figure 1 As shown, a fully sealed spray gun mouth of a powder spraying room, its upper end is connected with the top 1 of the powder spraying room, the upper flexible belt 2 is fixed on the winding roller 4, and the winding roller 4 elastically unwinds the upper flexible belt 2 . The lower flexible belt 3 is fixed on the lower roll 5, and the lower roll 5 elastically unwinds the flexible belt 3. The electrostatic dust spray gun 6 is fixed in the middle of the upper flexible belt 2 and the lower flexible belt 3, and is driven by a reciprocating machine to move up and down to spray powder on the workpiece in the powder spraying chamber.

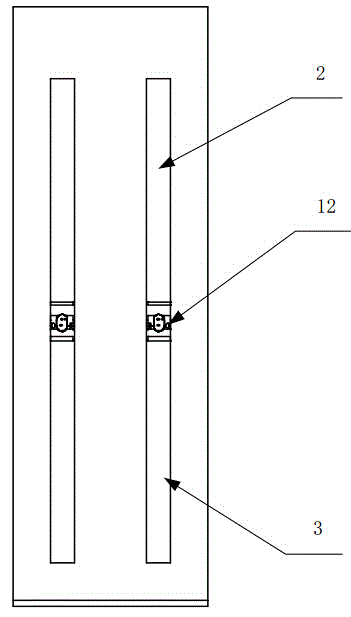

[0017] Such as figure 2 As shown, the spray gun 6 is fixed in the middle of the upper flexible belt 2 and the lower flexible belt 3 by using the rotary latch 12, which is convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com