X-ray sources

a source and x-ray technology, applied in the field of x-ray sources, can solve problems such as reducing the target lifetime, and achieve the effects of good thermal matching, low distortion, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

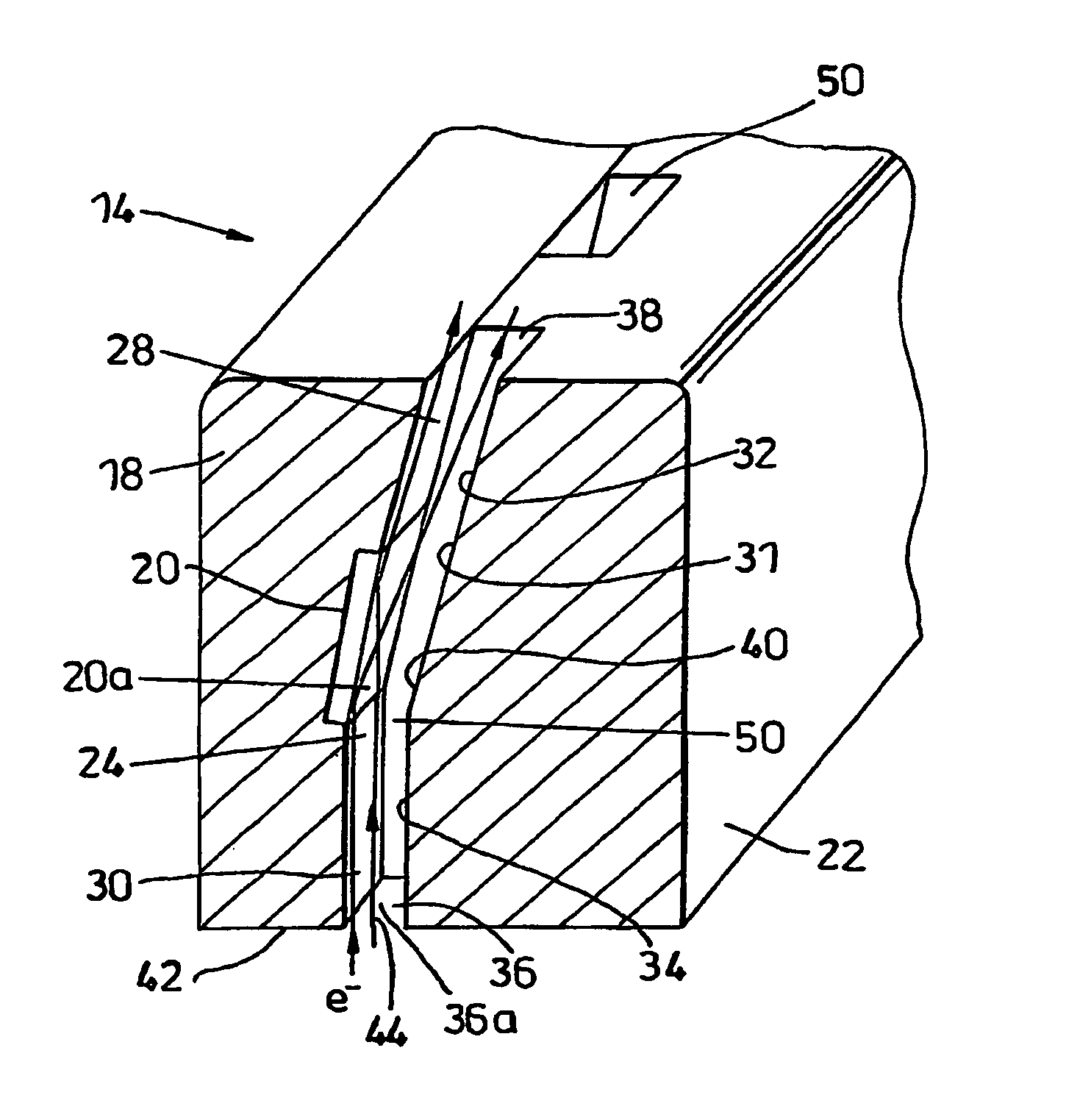

[0039]Referring to FIG. 1, an X-ray tube according to the invention comprises a multi-element electron source 10 comprising a number of elements 12 each arranged to produce a respective beam of electrons, and a linear anode 14, both enclosed in a tube envelope 16. The electron source elements 12 are held at a high voltage negative electrical potential with respect to the anode.

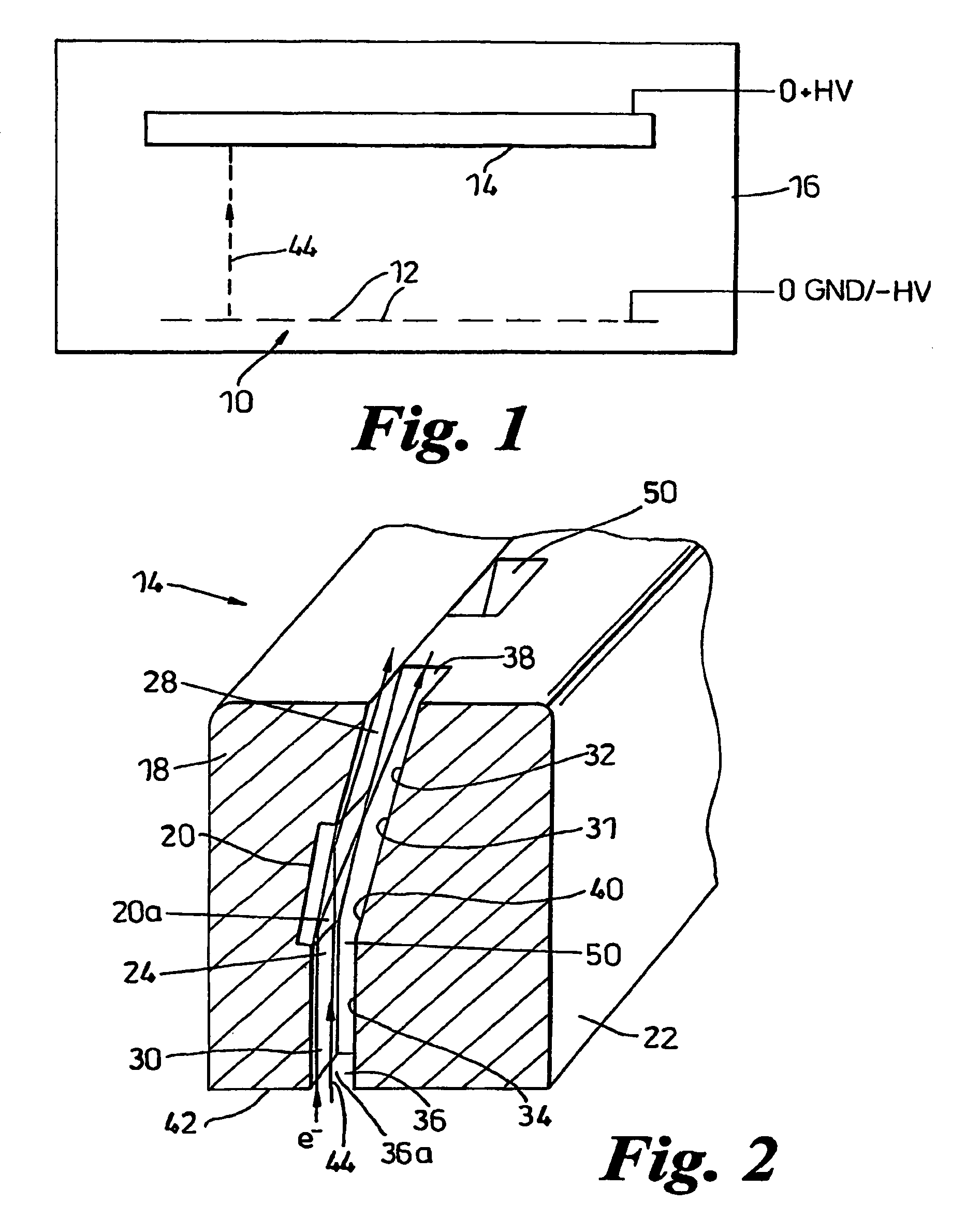

[0040]Referring to FIG. 2, the anode 14 is formed in two parts: a main part 18 which has a target region 20 formed on it, and a collimating part 22, both of which are held at the same positive potential, being electrically connected together. The main part 18 comprises an elongate block having an inner side 24 which is generally concave and made up of the target region 20, an X-ray collimating surface 28, and an electron aperture surface 30. The collimating part 22 extends parallel to the main part 18. The collimating part 22 of the anode is shaped so that its inner side 31 fits against the inner side 24 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com