Pigment, preparation method, thermal control coating containing pigment and preparation method

A thermal control coating and pigment technology, applied in coating, reflective/signal coating, etc., can solve problems such as low reflectivity, difficult to meet, insufficient MgO reflectivity, etc., achieve dense paint film, good bonding force, and solve the appearance rough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

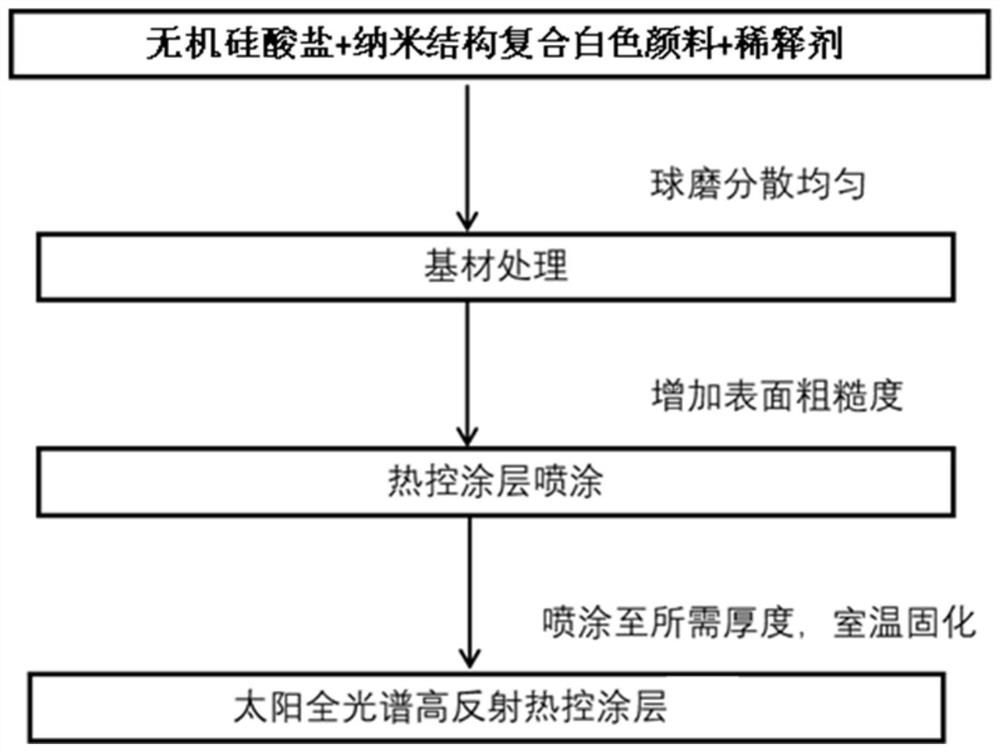

[0039] The preparation method of described a kind of pigment is characterized in that, comprises the following steps:

[0040] (1) hot injection of the mixed solution of magnesium sulfate and zinc sulfate in the sodium silicate solution, react;

[0041] (2) separating the reaction product in the mixed solution in step (1) from the solution, cleaning and drying;

[0042] (3) Sintering the product obtained in step (2) to obtain MgZnO / SiO 2 Core-shell nanostructure composite powder.

[0043] Further, in step (1), the concentration of the mixed solution of magnesium sulfate and zinc sulfate is 0.25~0.5mol / L, and the molar ratio of magnesium sulfate and zinc sulfate is 1~1.2:9; The concentration of sodium silicate solution is 1.0~ 1.5mol / L.

[0044] Further, in step (1), the mixed solution of magnesium sulfate and zinc sulfate is injected into the sodium silicate solution by hot injection at room temperature, and the speed of hot injection is 1 to 5ml / s; in step (1), The reacti...

Embodiment 1

[0057] Pigment MgZnO / SiO 2 Preparation of core-shell nanostructure composite powder-1:

[0058] (1) Prepare a mixed solution of magnesium sulfate and zinc sulfate with a molar ratio of 1:9 and a 1.0mol / L sodium silicate solution as a precursor solution. The concentration of the mixed solution of sulfate is 0.5mol / L. The salt mixed solution is injected into the sodium silicate solution; the solvent is deionized water; the speed of hot injection is 1-5ml / s; in the step (1), the reaction time is 10-20min.

[0059] (2) After the hot injection reaction, aging and centrifugation were carried out, and the mixed solution was centrifuged at 9000rpm for 6 minutes to separate the reaction product from the solution, washed 3 times with deionized water, and dried at 80°C for 24 hours;

[0060] (3) Sinter the dried product at 500°C to obtain MgZnO / SiO 2 Nanostructure composite powder-1.

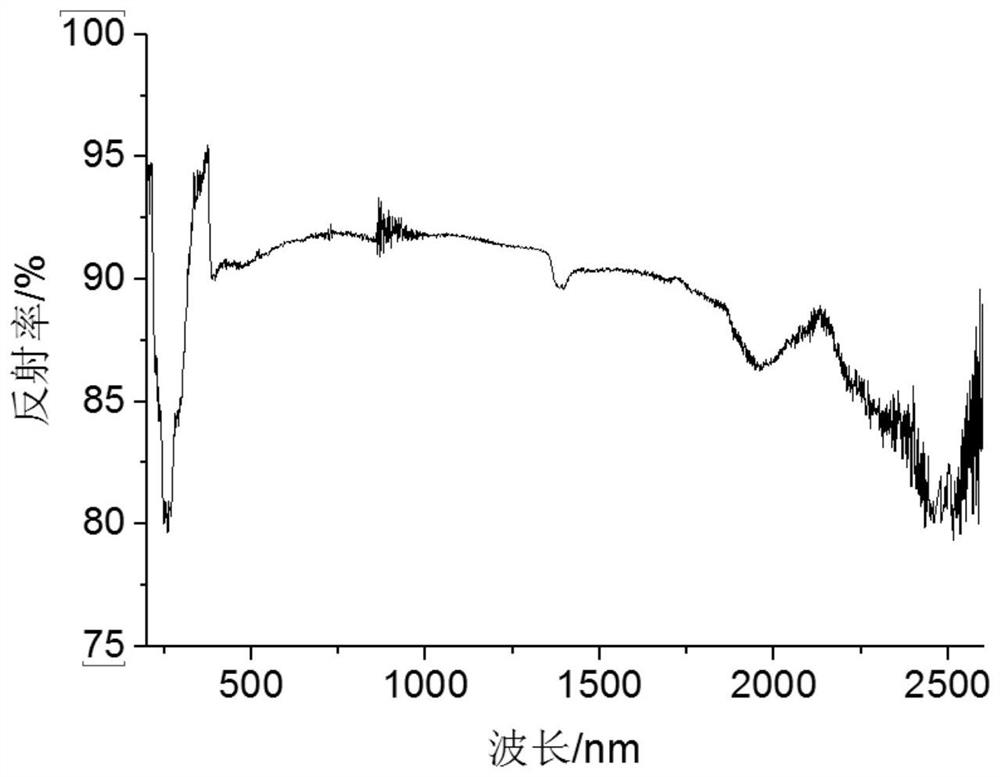

[0061] Contains MgZnO / SiO 2 The preparation of thermal control coating (solar full-spectrum high re...

Embodiment 2

[0068] Pigment MgZnO / SiO 2 Preparation of core-shell nanostructure composite powder-2:

[0069] (1) Prepare a mixed solution of magnesium sulfate and zinc sulfate with a molar ratio of 1:9 and 1.0MOL / L sodium silicate solution as a precursor solution. The concentration of the mixed solution of sulfate is 0.5MOL / L. The salt mixed solution is injected into the sodium silicate solution; the solvent is deionized water; the speed of hot injection is 1-5ml / s; in step (1), the reaction time is 10-20min;

[0070] (2) After the hot injection reaction, aging and centrifugation were carried out; the mixed solution was centrifuged at 9000rpm for 6 minutes to separate the reaction product from the solution, washed 3 times with deionized water, and dried at 80°C for 24 hours;

[0071] (3) Sinter the dried product at 400°C to obtain MgZnO / SiO 2 Nanostructure composite powder-2.

[0072] Contains MgZnO / SiO 2 Preparation of thermal control coating of core-shell nanostructure composite powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com