Method and device for improving grade of medium-and-low-temperature solar thermal power and integrally separating CO2

A CO2, solar evaporator technology, applied in the energy field, can solve the problems of very large impact on system performance, decreased system efficiency, large amount of exhaust gas, etc., to improve the thermal performance of the cycle, increase the output power of the system, and improve the conversion rate of methane. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

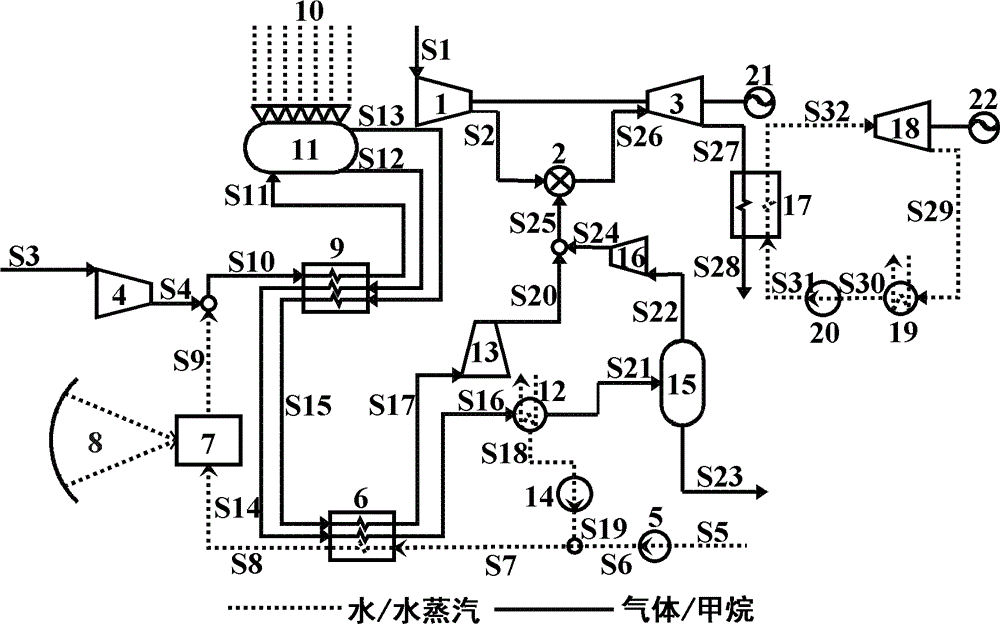

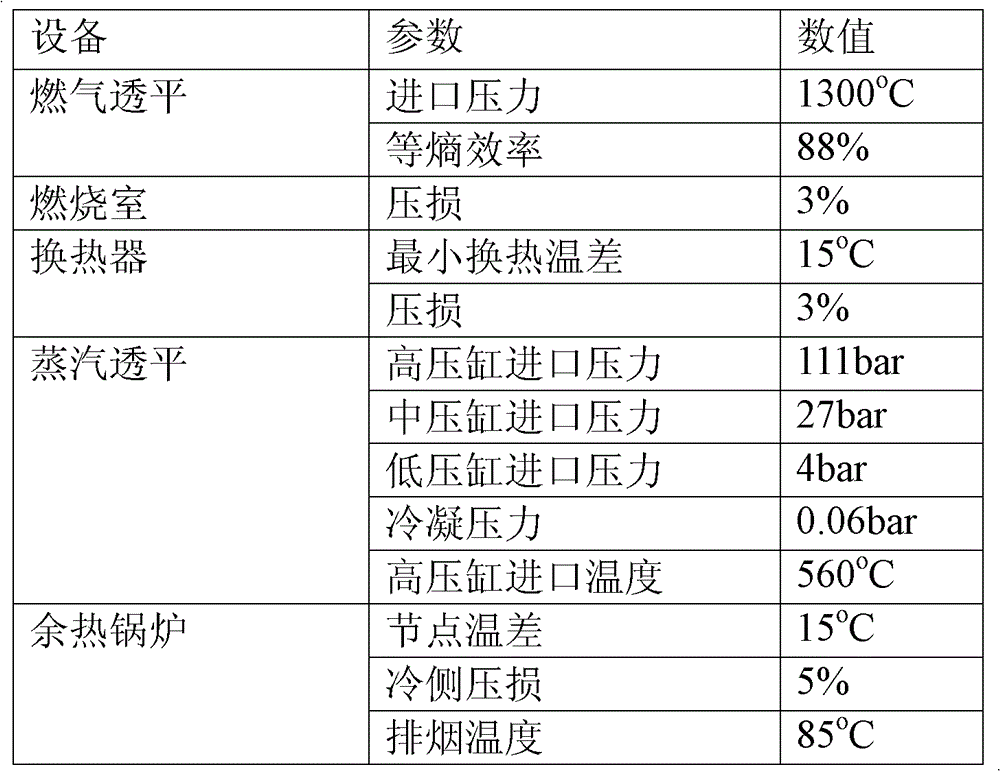

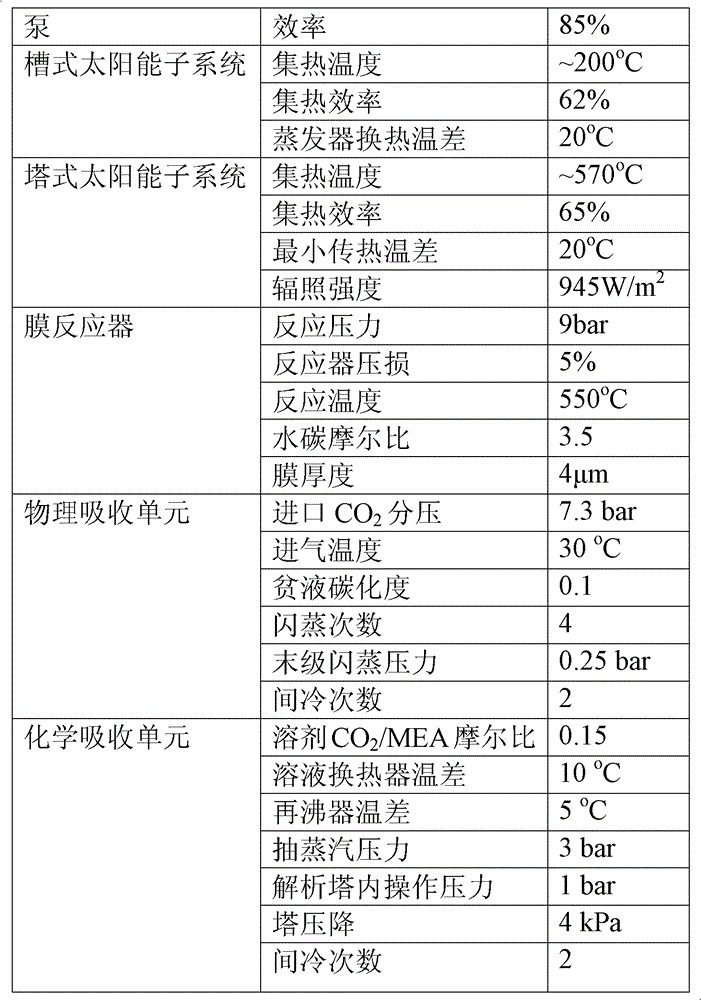

[0067] This medium and low temperature solar thermal energy grade promotion provided by the present invention and CO 2 The integrated separation method and device is to introduce a palladium-based alloy membrane structure with strong hydrogen permeability into the methane / steam reforming reaction, thereby greatly improving the reaction conditions, increasing the conversion rate of methane, and realizing CO 2 separate. The latent heat of vaporization of reforming steam is provided by parabolic trough solar energy at 200°C, which is converted into steam internal energy and converted into chemical energy of syngas by participating in the reforming reaction. At the same time, the 550°C concentrating tower solar energy is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com