Preparation method of electromagnetic shielding multi-layer composite material in electric vacuum device

A multi-layer composite material, electromagnetic shielding technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of reducing the performance of Mo/Cu/Fe materials, low machining yield, Cu/Fe Low strength and other problems, to achieve the effect of good magnetic screen effect, good thermal matching and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

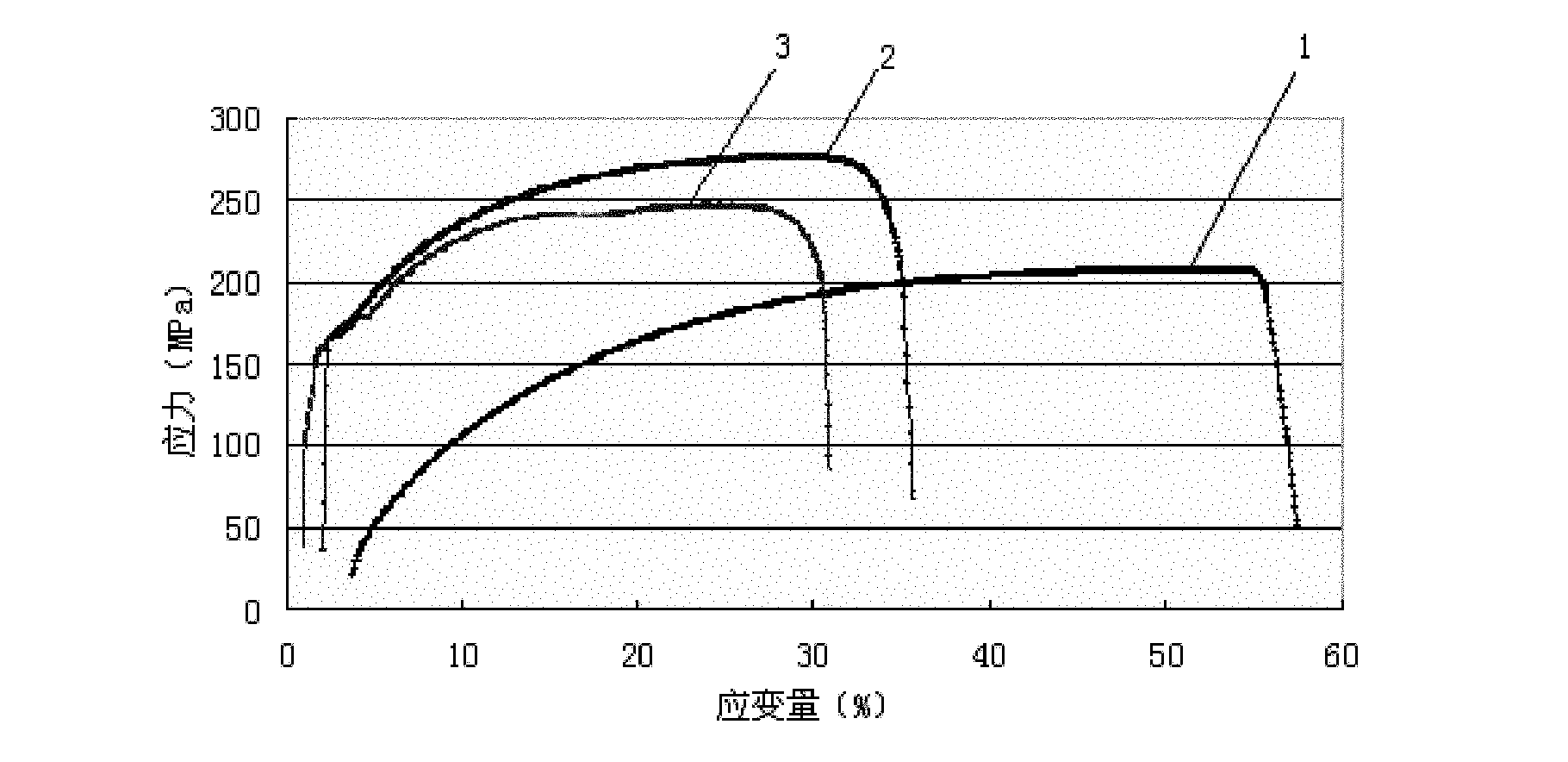

Embodiment 1

[0029] Select DT9 electrical pure iron and TU1 oxygen-free copper sheets produced by vacuum induction and electroslag remelting smelting processes, both of which are 2mm thick, and cut and prepare materials according to the size of 100×30mm; the prepared materials are respectively polished with water abrasive paper and ultrasonic Cleaning, 10%NaOH+10%Na 2 CO 3 Alkaline solution and its concentration is 15% HCl+10% HNO 3 The surface pretreatment of the acid solution is carried out in the steps of acid-base cleaning and final alcohol cleaning; then the two metal surfaces are roughened with a steel brush to expose the fresh metal; finally, the riveted laminate is assembled in the order of Cu / Fe / Cu, and immediately Carry out cold rolling and compounding with a reduction rate of 70%; carry out multiple times of inert gas protection annealing and cold rolling on the rolled parts. As thin as 0.3mm, Cu / Fe / Cu foil is obtained; finally, a molybdenum sheet with a surface roughness of R...

Embodiment 2

[0031] Select DT8 electrical pure iron and TU1 oxygen-free copper sheet produced by vacuum induction and electroslag remelting smelting process. Cleaning, 10%NaOH+10%Na 2 CO 3 Alkaline solution and its concentration is 15% HCl+10% HNO 3 The surface pretreatment of the acid solution is carried out in the steps of acid-base cleaning and final alcohol cleaning; then the two metal surfaces are roughened with a steel brush to expose the fresh metal; finally, the riveted laminate is assembled in the order of Cu / Fe / Cu, and immediately Carry out hot rolling compounding with a reduction rate of 50% at a temperature of 850°C; and perform multiple times of inert gas protection annealing and cold rolling on the rolled piece, the annealing temperature is 500-550°C, and the deformation amount of each pass is: 20%- 30%, thinned to 0.1mm to obtain Cu / Fe / Cu foil; finally select the WCu sheet with a surface roughness of Ra1.6, stack the WCu sheet with the rolled Cu / Fe / Cu foil, and put it into...

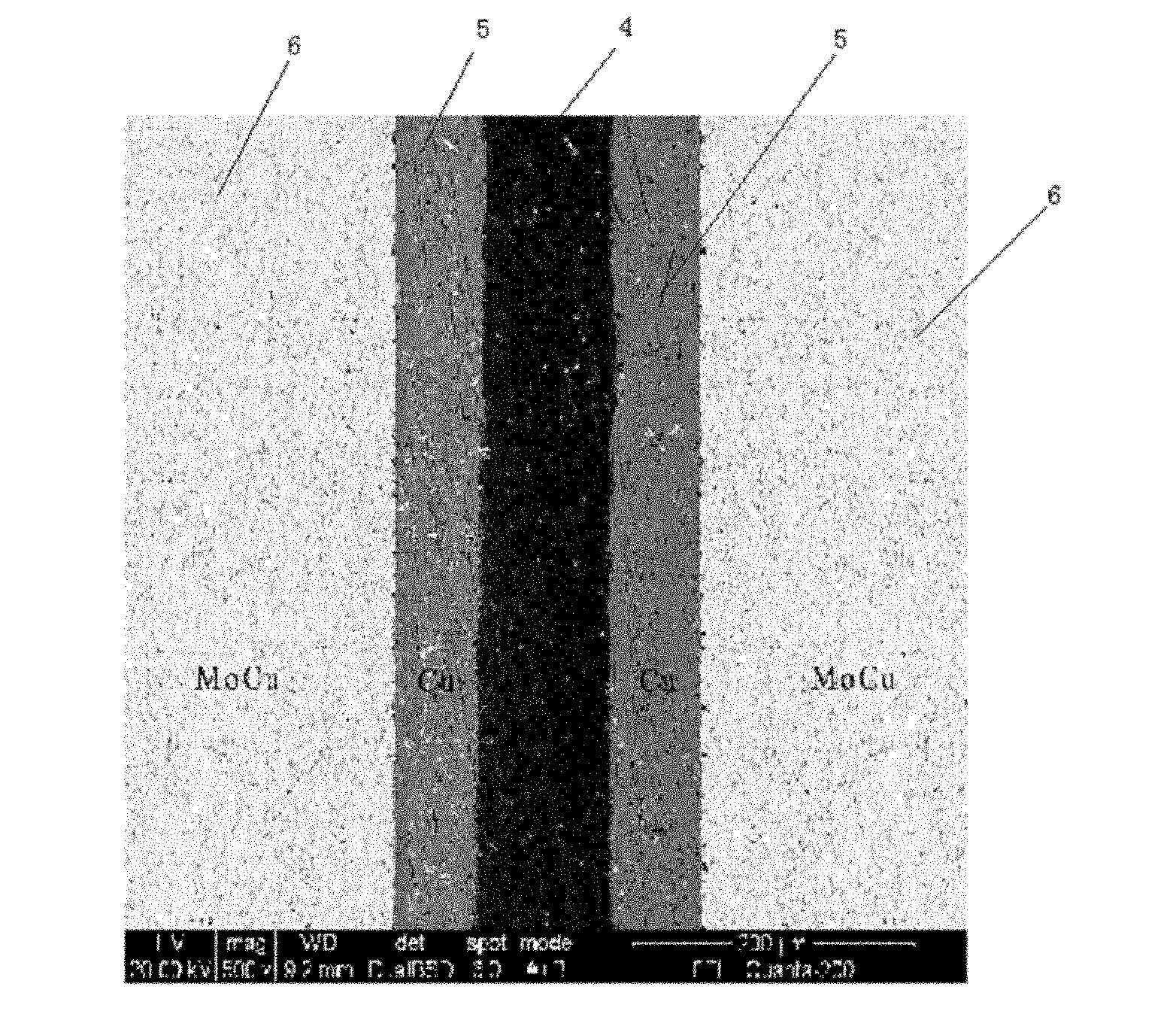

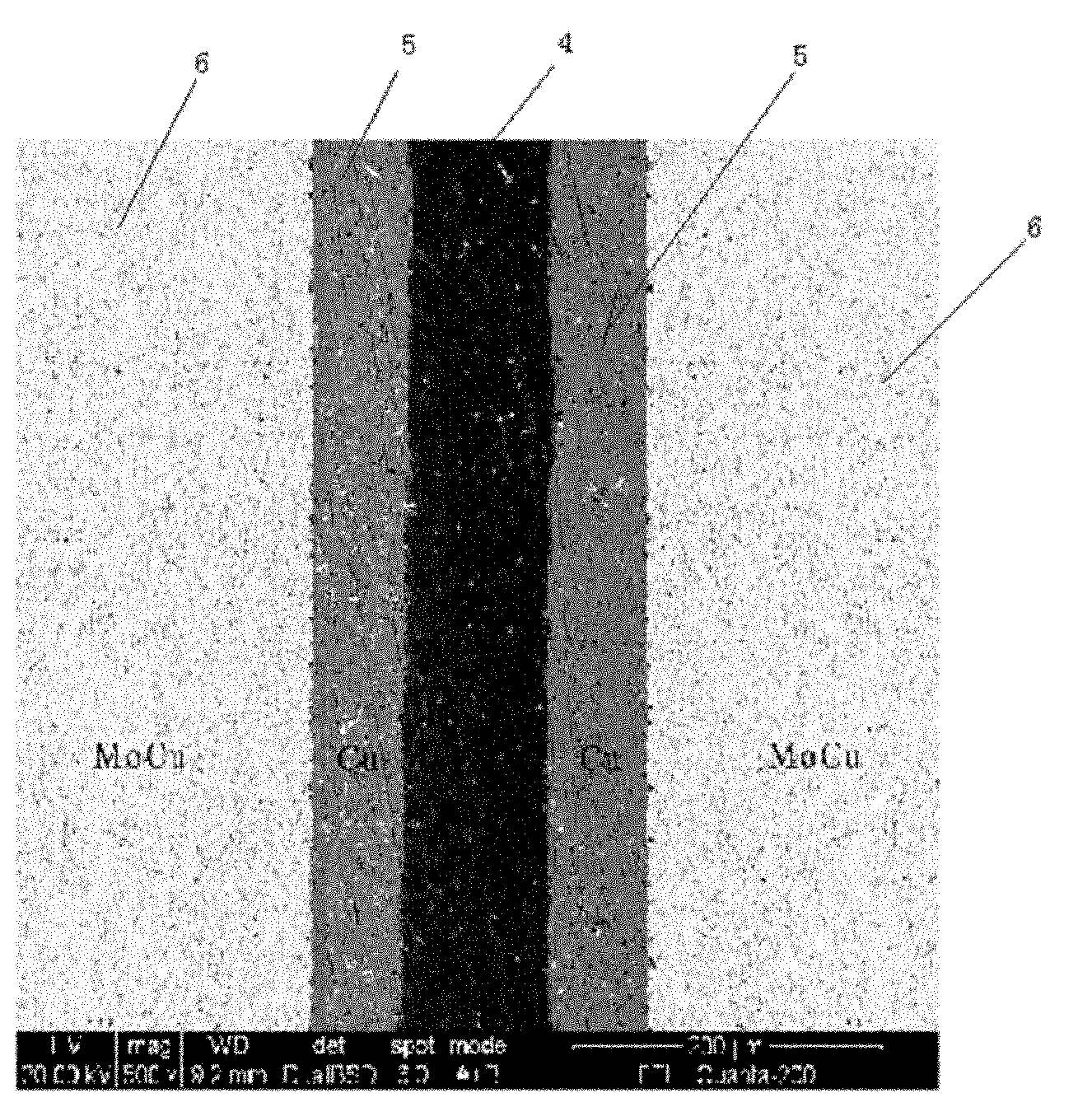

Embodiment 3

[0033] Select DT8 electrical pure iron and TU1 oxygen-free copper sheet produced by vacuum induction and electroslag remelting smelting process. Cleaning, 10%NaOH+10%Na 2 CO 3 Alkaline solution and its concentration is 15% HCl+10% HNO 3The surface pretreatment of the acid solution is carried out in the steps of acid-base cleaning and final alcohol cleaning; then the two metal surfaces are roughened with a steel brush to expose the fresh metal; finally, the riveted laminate is assembled in the order of Cu / Fe / Cu, and immediately Carry out hot rolling compounding with a reduction rate of 50% at a temperature of 820°C; carry out multiple hydrogen protection annealing and cold rolling on the rolled parts, annealing temperature: 550-600°C, and pass deformation: 30%-40 %, thinned to 0.2mm to obtain Cu / Fe / Cu foil; finally select the MoCu sheet with a surface roughness of Ra1.0, laminate the MoCu sheet with the rolled Cu / Fe / Cu foil, and put it in a vacuum Diffusion welding is carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com