Vertical heat accumulating type reduction furnace

A reduction furnace, regenerative technology, applied in the field of regenerative vertical reduction furnace, can solve the problems of vacuum atmosphere damage in the tank, difficulty in closing the lower tank mouth, thermal deformation of the lower tank mouth, etc., to achieve short construction period and energy saving The effect of remarkable effect and short recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

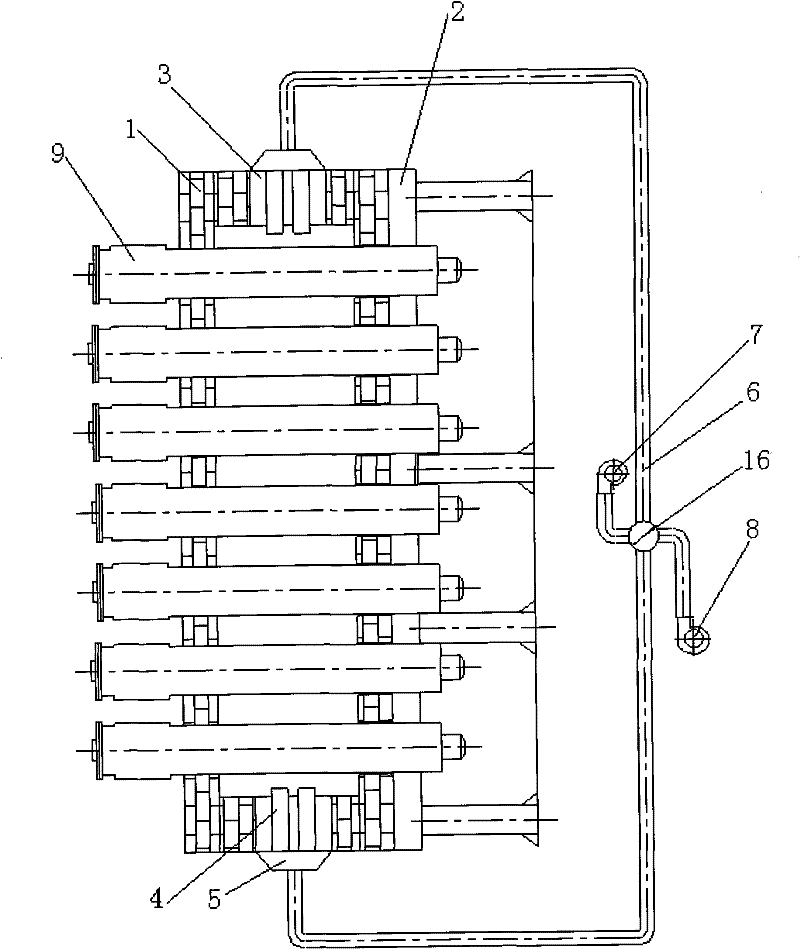

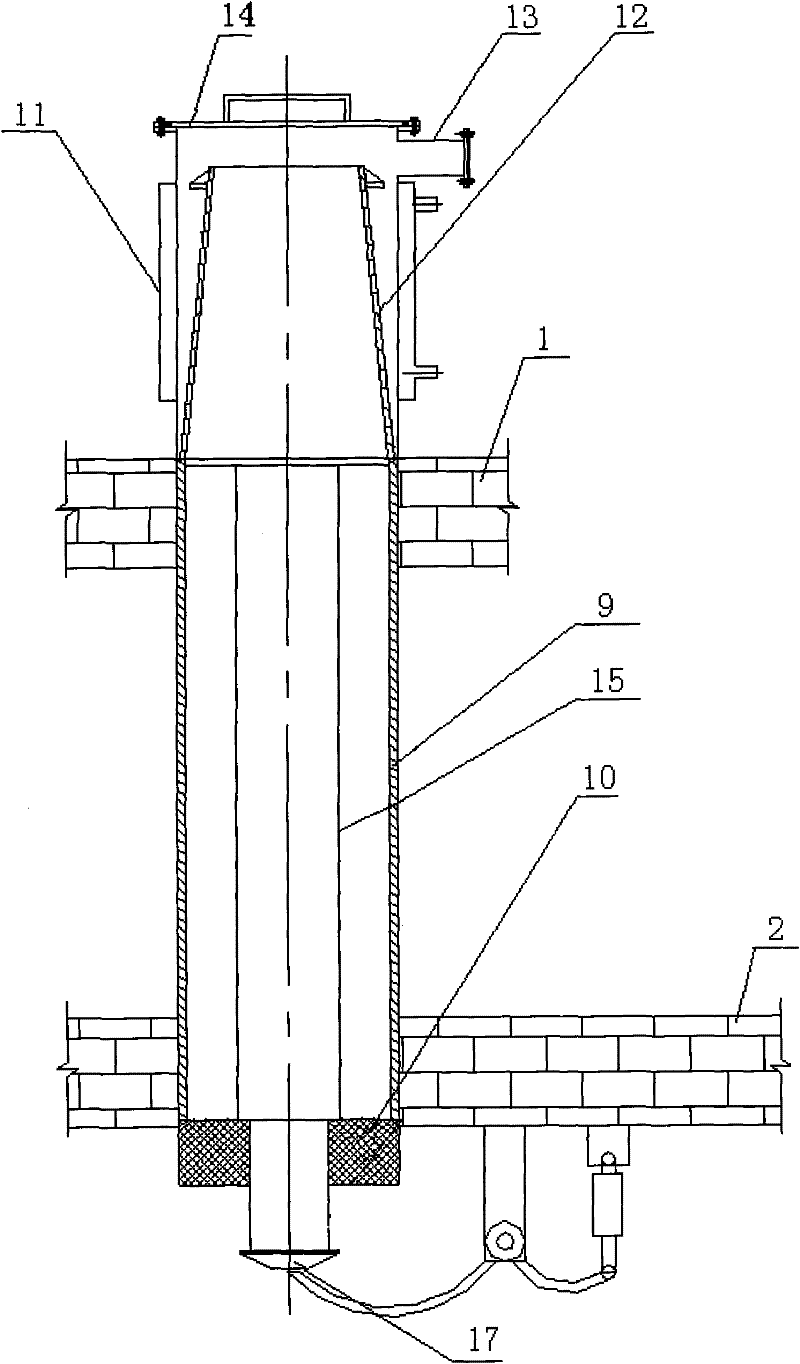

[0019] A regenerative vertical reduction furnace, the structure of which comprises:

[0020] Reduction furnace body 1 - the furnace body is a cavity-type cylindrical shell made of refractory materials, and the bottom of the furnace body is supported and fixed by a desktop support frame 2; the vertical side wall of the furnace body is equipped with a regenerative heating Cavity 3;

[0021] Regenerative heating device - the heating device includes a device shell that is adapted to the regenerative heating chamber on the vertical side wall of the reduction furnace body, and the fuel and combustion gas nozzles 4 and 5 are arranged in the shell;

[0022] Fuel and combustion-supporting gas inlet device - the device structure includes a delivery pipe 6 connected to the rear of the regenerative heating device shell, an induced draft fan 7 and a blower 8 fixedly connected to the tail end of the delivery pipe;

[0023] Reduction reaction tank 9 - the reaction tank is a vertical reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com