Efficient low-emission high-temperature low-oxygen hot blast stove

A high-temperature, low-oxygen, hot-blast stove technology, applied in the field of hot-blast stoves and hot-blast stoves in the metallurgical industry, can solve the problems of low oxygen content and high preheating temperature of combustion-supporting air, achieve uniform flue gas temperature field, improve thermal efficiency, and eliminate local high temperatures zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

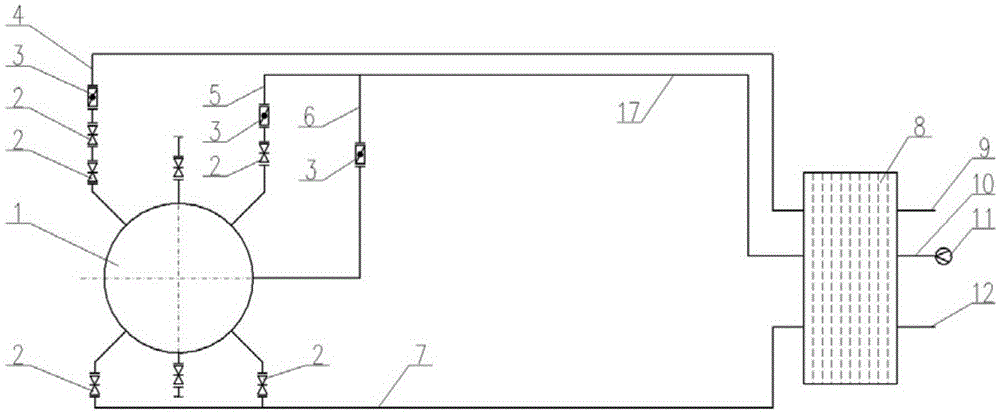

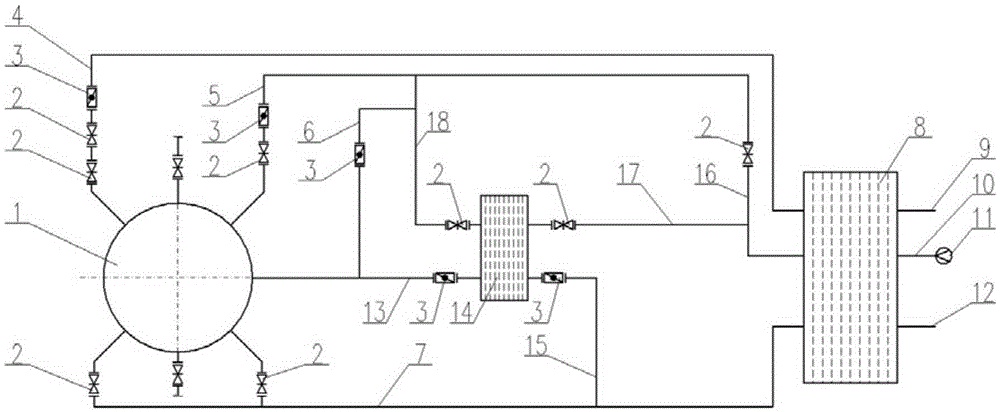

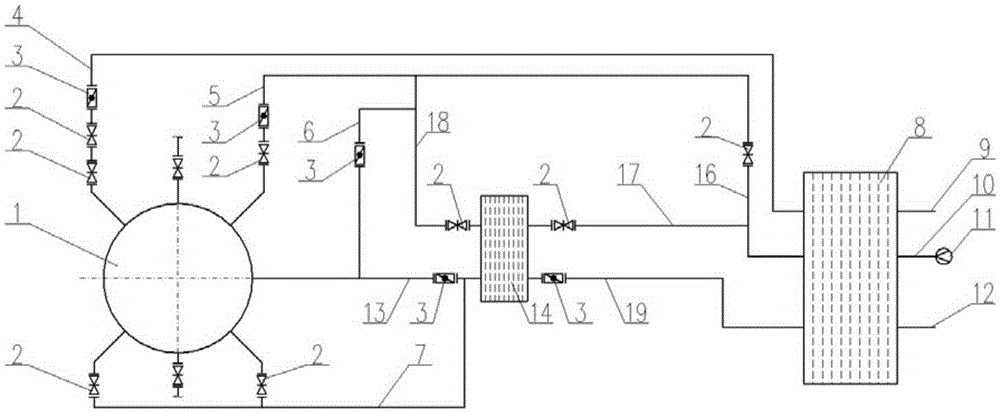

[0034] figure 1 , figure 2 and image 3 Respectively the specific implementation of the present invention

[0035] Depend on figure 1 It can be seen that the high-efficiency, low-emission, high-temperature and low-oxygen hot blast stove of the present invention includes: hot blast stove 1, shut-off valve 2, regulating valve 3, gas pipeline 4 for hot blast stove, combustion-supporting air pipeline 5 for hot blast stove, high-temperature mixed gas flue 6, low-temperature smoke Road 7, low temperature preheating system 8, gas main pipe 9 from the pipe network, combustion air main pipe 10, combustion fan 11 for hot blast stove, flue 12 after heat exchange, combustion air low temperature preheating pipe 17.

[0036] The low calorific value gas from the gas pipeline network enters the low-temperature preheating system 8 through the gas main pipe 9 from the pipeline network, preheats the gas to about 200°C, passes through the gas pipeline 4 for the hot blast stove, the regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com