A Multipurpose High Temperature Preheating System for Hot Blast Stove

A hot blast stove and multi-purpose technology, applied in the field of hot blast stoves and hot blast stoves in the metallurgical industry, can solve the problems such as the rapid decline of the strength of the furnace grate and the collapse of the regenerator, so as to improve the on-site reaction speed, reduce the occupation of land and investment, shorten the The effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

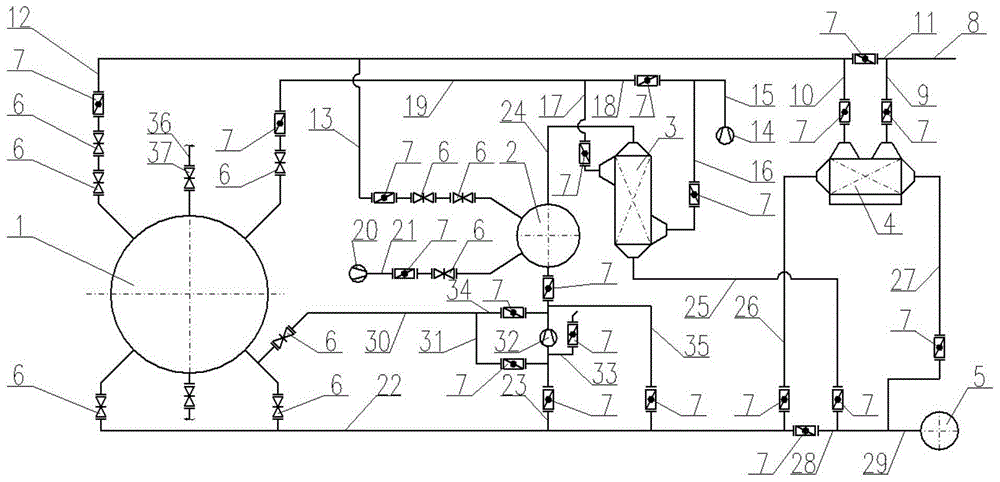

[0031] figure 1 Is the specific implementation of the present invention

[0032] Depend on figure 1 It can be seen that a kind of multipurpose hot blast stove high temperature preheating process of the present invention comprises: hot blast stove 1, flue gas stove 2, air heat exchanger 3, gas heat exchanger 4, chimney 5, shut-off valve 6, regulating shut-off valve 7, Gas inlet pipe 8, heat exchanger gas main pipe 9, heat exchanger gas main pipe 10, gas bypass pipe 11, preheated gas pipe 12, flue gas furnace gas pipe 13, combustion fan 14, air main pipe 15, Inlet heat exchanger air main pipe 16, heat exchanger air main pipe 17, air bypass pipe 18, preheated air pipe 19, flue gas stove combustion fan 20, flue gas inlet air pipe 21, hot blast stove flue 22, Low temperature flue 23 for flue gas inlet, high temperature flue 24 for flue gas outlet, 25 flue for air heat exchanger, 26 flue for gas heat exchanger, 27 flue for gas heat exchanger, flue gas bypass pipe 28. Flue gas mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com