Bionic phase change energy storage steam cavity module

A technology of steam chamber and bionic phase, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of low heat storage and heat release rate, uneven heat transfer during heat storage, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

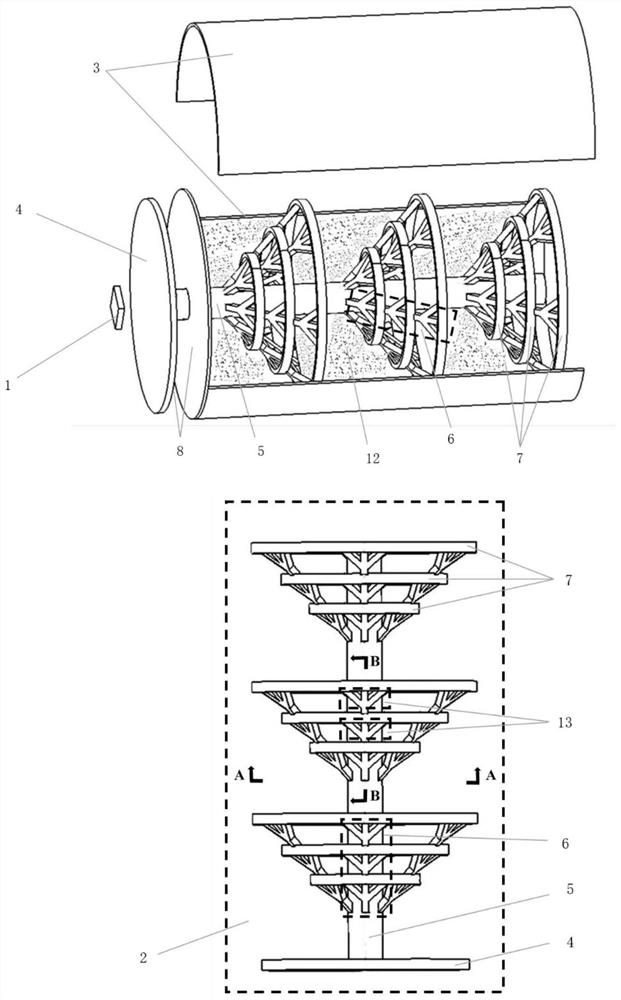

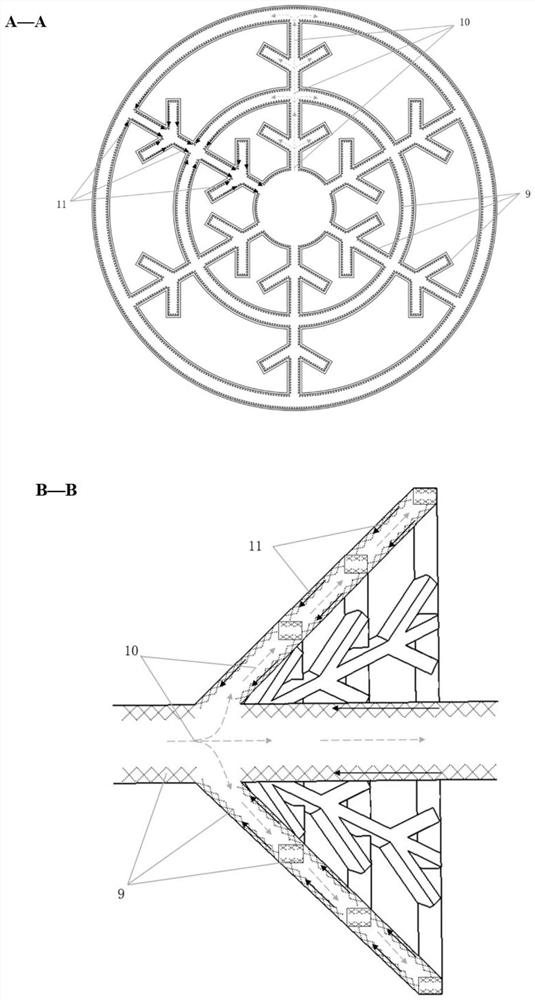

[0034] figure 1 with figure 2 It is a schematic structural diagram of a biomimetic phase transitional energy vapor chamber provided by the present invention.

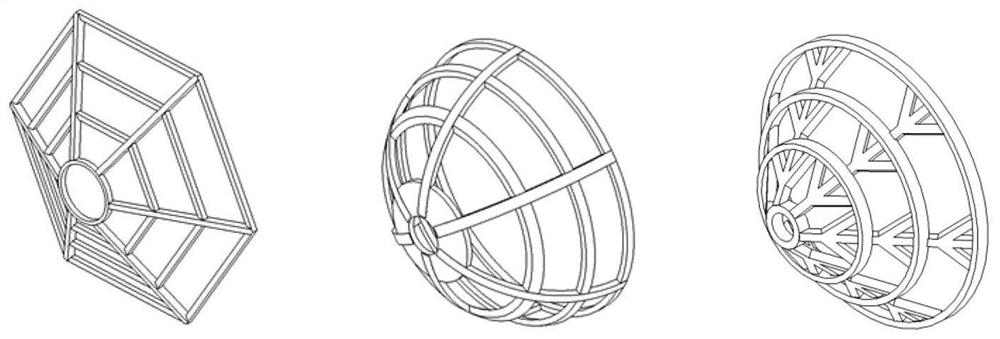

[0035] The present invention will be specifically described in conjunction with the accompanying drawings. A bionic phase transition storage vapor module, the overall structure is composed of a tree vapor cavity 2, a phase transform container 3, a tree vapor chamber 2, a phase change, a phase change container 3 filled a phase change material 12. The tree vapor chamber 2 includes at least one vapor chamber plate 4, a columnar vapor cavity 5, a plurality of emitted rigid steam cavity 6 and an annular vapor chamber rib 7 structure, from the ground to form a tree root, stem, bionic bionic structure feature. One side of the steam chamber flat plate 4 is in contact with the heat source 1, and the surface area is more than ten times the heat source 1, so that the heat of the heat source 1 is uniformly diffused to the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com