Efficient dehaze waste heat recovery energy-saving emission reduction device

A waste heat recovery, energy-saving and emission-reduction technology, applied to heat exchange equipment, heat exchanger shells, heat exchanger types, etc., can solve problems such as increased maintenance costs, and achieve reduced emissions, improved efficiency, and high-efficiency heat exchange capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

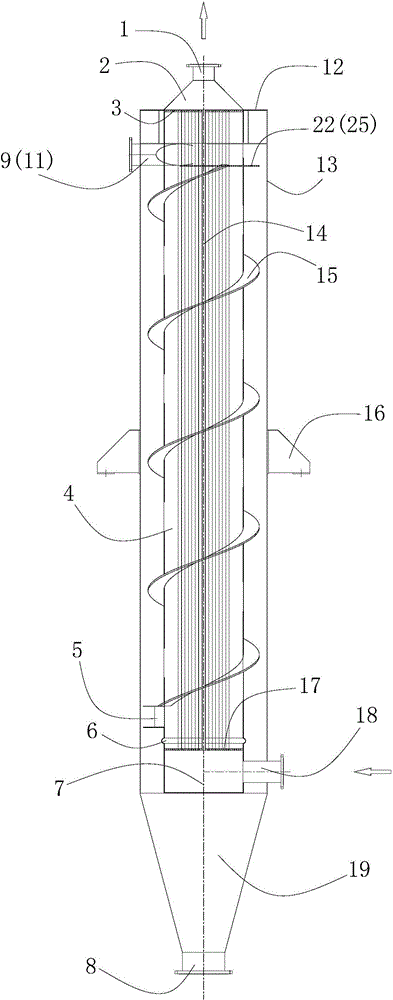

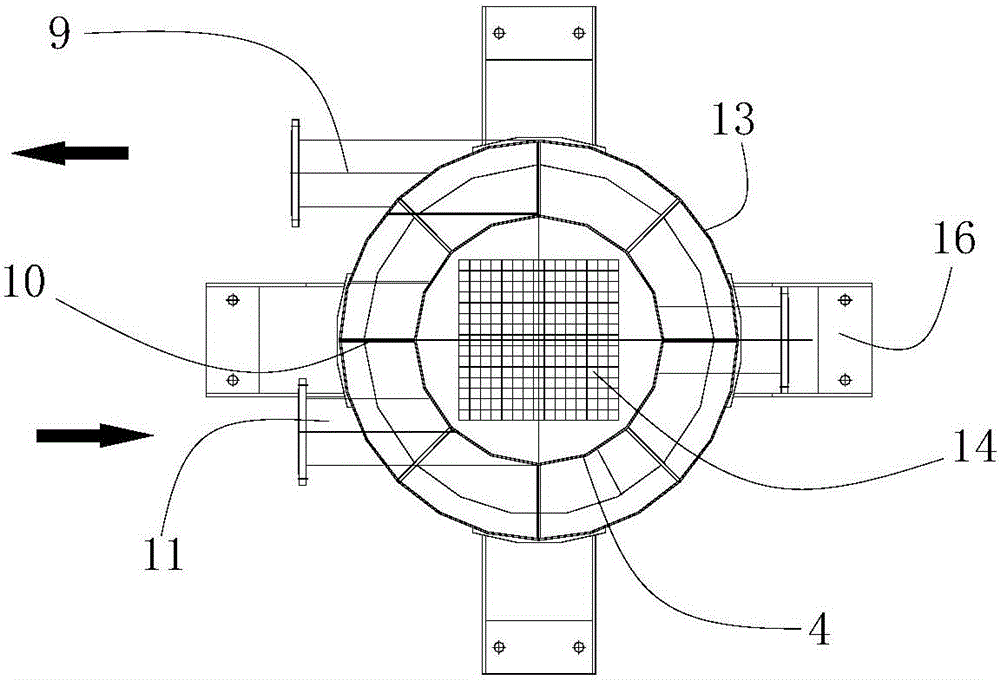

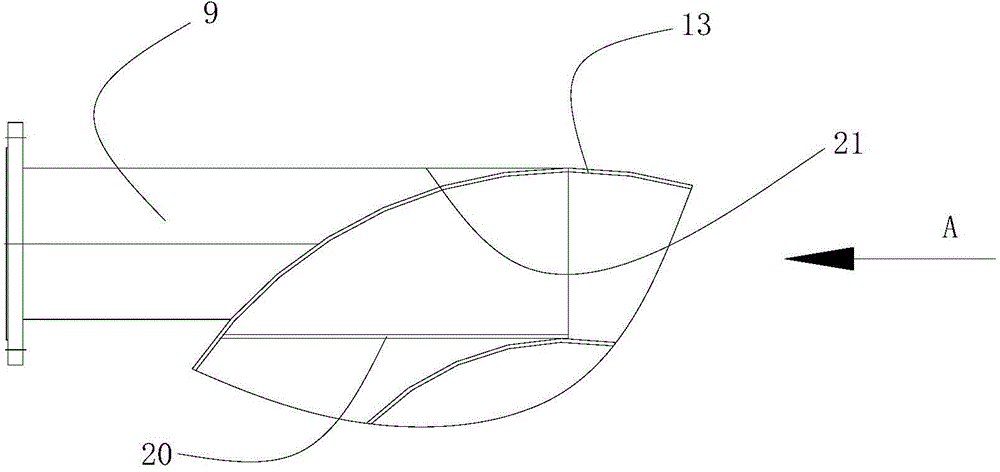

[0029] refer to figure 1 and figure 2, is a high-efficiency haze removal waste heat recovery energy-saving emission reduction device, installed vertically with the tail flue of the boiler, including SP heat exchange tube 14, upper tube plate 3, lower tube plate 17, inner cylinder 4, spiral plate 15 and outer Cylinder 13, SP heat exchange tube 14 is built in the inner cylinder 4, the upper end of SP heat exchange tube 14 is connected with the upper tube plate 3, and the lower end is connected with the lower tube plate 17; the upper end of the inner cylinder 4 is connected with the upper tube plate 3 The outer circle of the tube is connected, and the lower end is connected with the expansion joint 6 and then connected with the outer circle of the lower tube plate 17. The expansion joint 6 is located between the SP heat exchange tube 14 and the inner cylinder 4; the upper section of the inner cylinder 4 is provided with a flue gas The inlet nozzle 11, the flue gas inlet nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com