Condensing and radiating heating panel

A radiative heat dissipation and panel technology, which is applied in the field of heat dissipation devices, can solve the problems of increasing the difficulty of the spacecraft thermal control system, and achieve the effects of no pump power consumption, uniform temperature and heat dissipation intensity distribution, and reduced self-weight and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

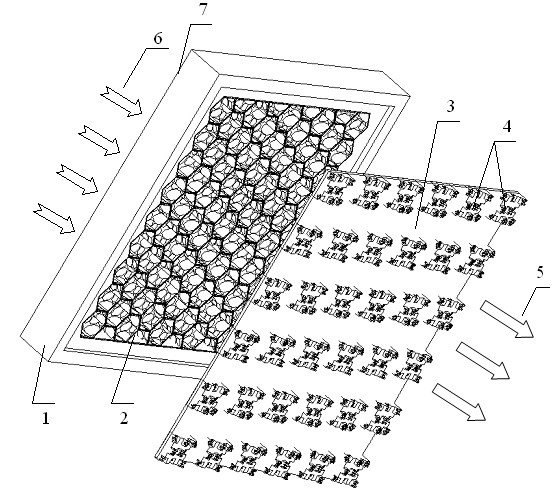

[0028] Carry out further detailed description below in conjunction with accompanying drawing:

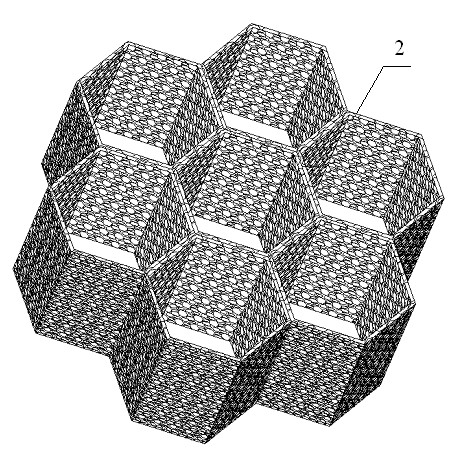

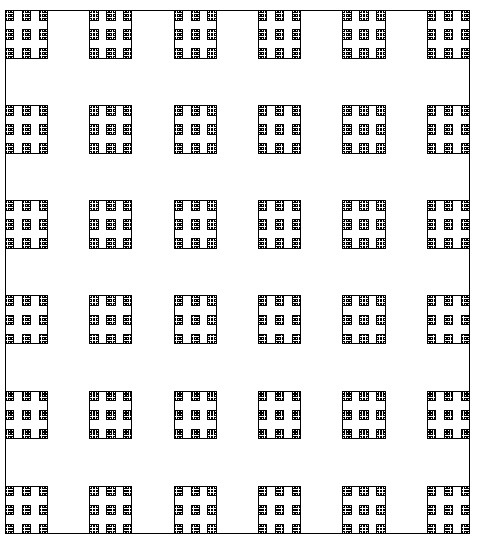

[0029] figure 1 The three-dimensional view of the condensing radiation heat dissipation plate is given. A condensation radiation heat dissipation plate is composed of a hollow heat conduction panel 1, a porous foam honeycomb structure liquid absorption core 2, a sintered core 8 and a gas-liquid two-phase fluid. The sintered core 8 is lined with the hollow heat conduction panel. 1, the liquid-absorbing core 2 fills the hollow part of the hollow heat-conducting panel 1 and is closely connected with the sintered core 8, and the gas-liquid two-phase fluid is immersed in the pore structure of the liquid-absorbing core 2 and the sintered core 8. The inner surface of the condensing radiation surface 3 of the hollow heat conduction panel is a superhydrophobic surface hydrophobic layer 13, and the outer surface is a fractal surface. It is a porous foam honeycomb structure.

[0030] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com