Flow baffling type demister

A mist eliminator and baffle type technology, which is applied in the field of baffle type mist eliminator and gas-liquid separation process, can solve the problems of high processing and manufacturing costs, complex technical structure, and difficult processing, so as to reduce mist entrainment, Simple structure and high demisting efficiency

Active Publication Date: 2015-05-13

CHINA PETROLEUM & CHEM CORP +1

View PDF8 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the process of separating the liquid phase from the gas phase in this technology, gas-liquid cross-flow can be realized, so the secondary entrainment effect of the gas relative to the liquid droplets is greatly reduced, but the technical structure is very complicated, the processing difficulty is relatively large, and the corresponding processing and production costs are relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034] A wet scrubber to purify flue gas 180,000Nm 3 / h, where the apparent water concentration is 10~15g / Nm 3 , The concentration of visible water in the exhaust gas after defogging by the present invention 3 , Defogging efficiency> 90%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Login to View More

Abstract

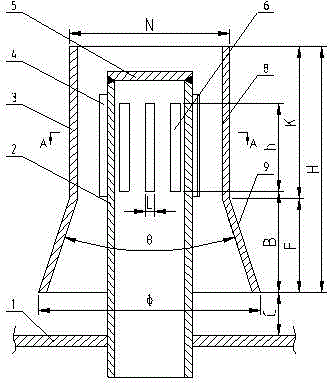

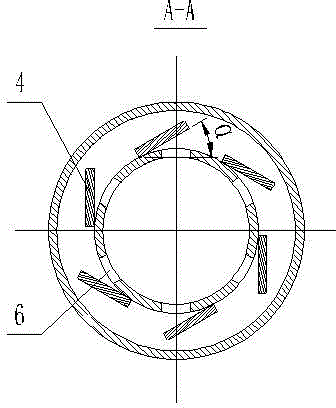

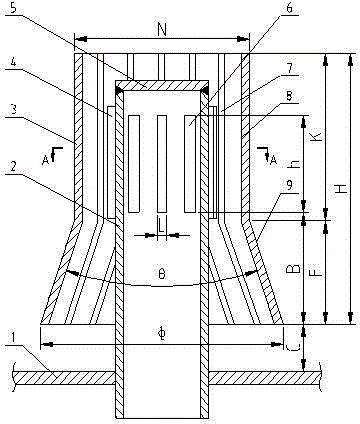

The present invention discloses a flow baffling type demister, which comprises a plurality of demisting assemblies aligned in parallel, wherein each demisting assembly comprises a gas rising pipe and an outer cylinder, the outer cylinder is arranged on the outer side of the gas rising pipe and is at the same axis line as the gas rising pipe, the gas rising pipe is fixed on a tower disk, the top portion of the gas rising pipe is provided with a sealing cover plate, the circumference of the gas rising pipe is provided with a plurality of seams, the gas rising pipe circumference close to each seam is provided with tangential diversion wings, and the outer cylinder comprises the straight cylinder section on the upper portion and the taper cylinder section on the lower portion. According to the flow baffling type demister, the separation of the liquid droplet and the gas is achieved through the flow baffling during the fluid flowing process; and the flow baffling type demister has characteristics of simple structure, easy installation and effective gas-liquid separation achieving, and is suitable for the gas-liquid separation process in the fields of chemical industry, environmental protection, and the like.

Description

Technical field [0001] The invention relates to a baffled demister, which belongs to the field of gas-liquid separation in chemical engineering, and is suitable for gas-liquid separation processes in the fields of chemical engineering and environmental protection. Background technique [0002] SO 2 And dust is an important cause of air pollution in our country, and it is also an air pollutant that our country currently focuses on controlling. At present, the wet process is mostly used in the field of environmental protection. In the wet process flue gas desulfurization process, the absorption tower is prone to produce "mist" with a particle size of 10-60 microns during operation, which not only contains water, but also contains sulfuric acid. , Sulfate, SO 2 And so on, causing pollution to the atmospheric environment, and at the same time causing serious corrosion to the exhaust tube and heat exchanger. Therefore, in the wet desulfurization process, the purified gas must be demi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D45/08B01D45/06

CPCB01D45/06B01D45/08

Inventor 方向晨彭德强王璐瑶王岩陈建兵孟凡飞陈新齐慧敏

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com