Shell and tube type heat exchanger with sharply enlarged accelerated flow zooming tube bundle and hollow ring

A shell-and-tube heat exchanger and hollow ring technology, applied in the field of heat transfer enhancement, can solve the problems of insufficient heat transfer enhancement efficiency, large fluid body resistance, weakened heat transfer, etc., so as to reduce the dead angle of flow and heat transfer, reduce Gas resistance, the effect of reducing gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

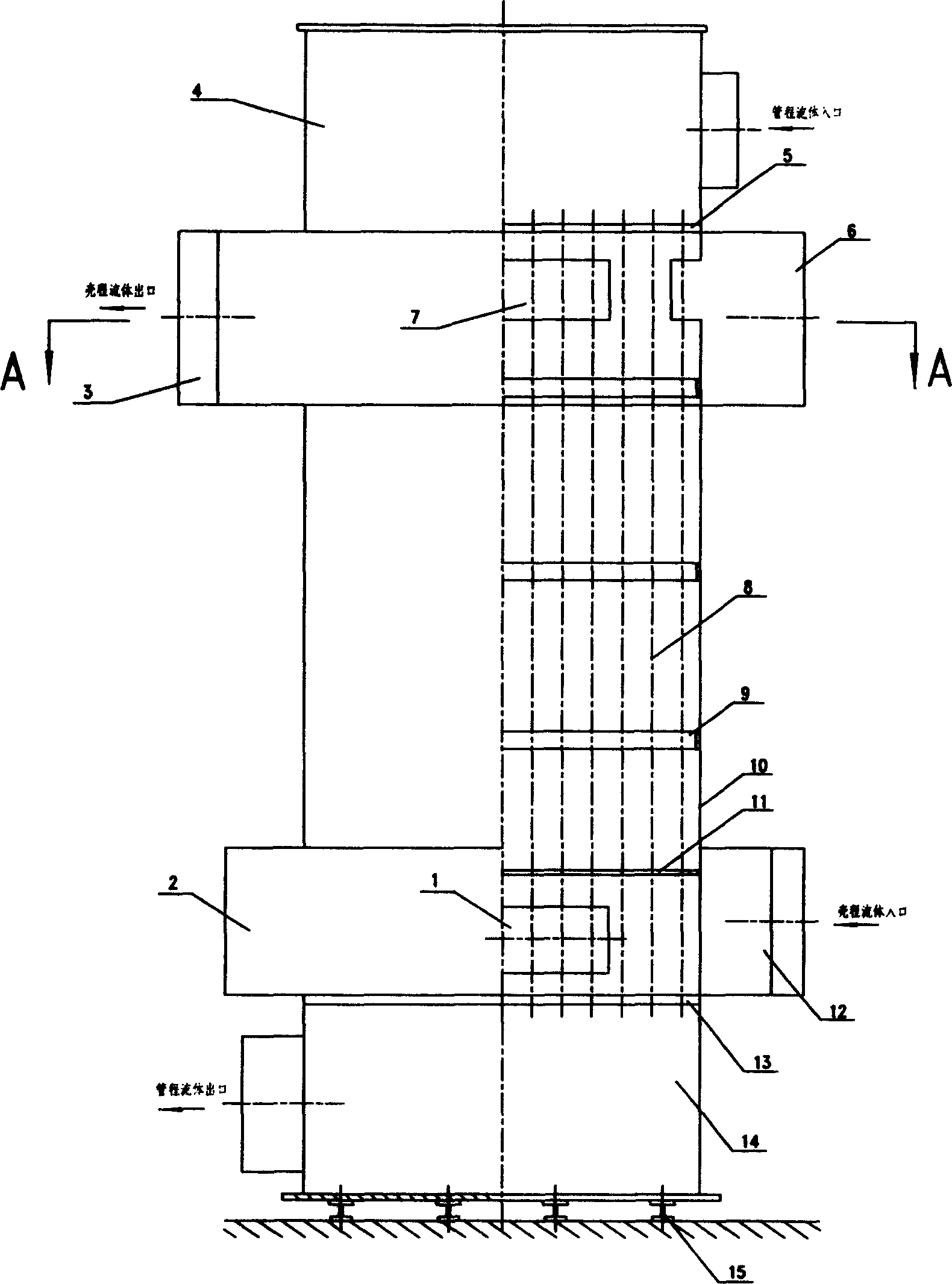

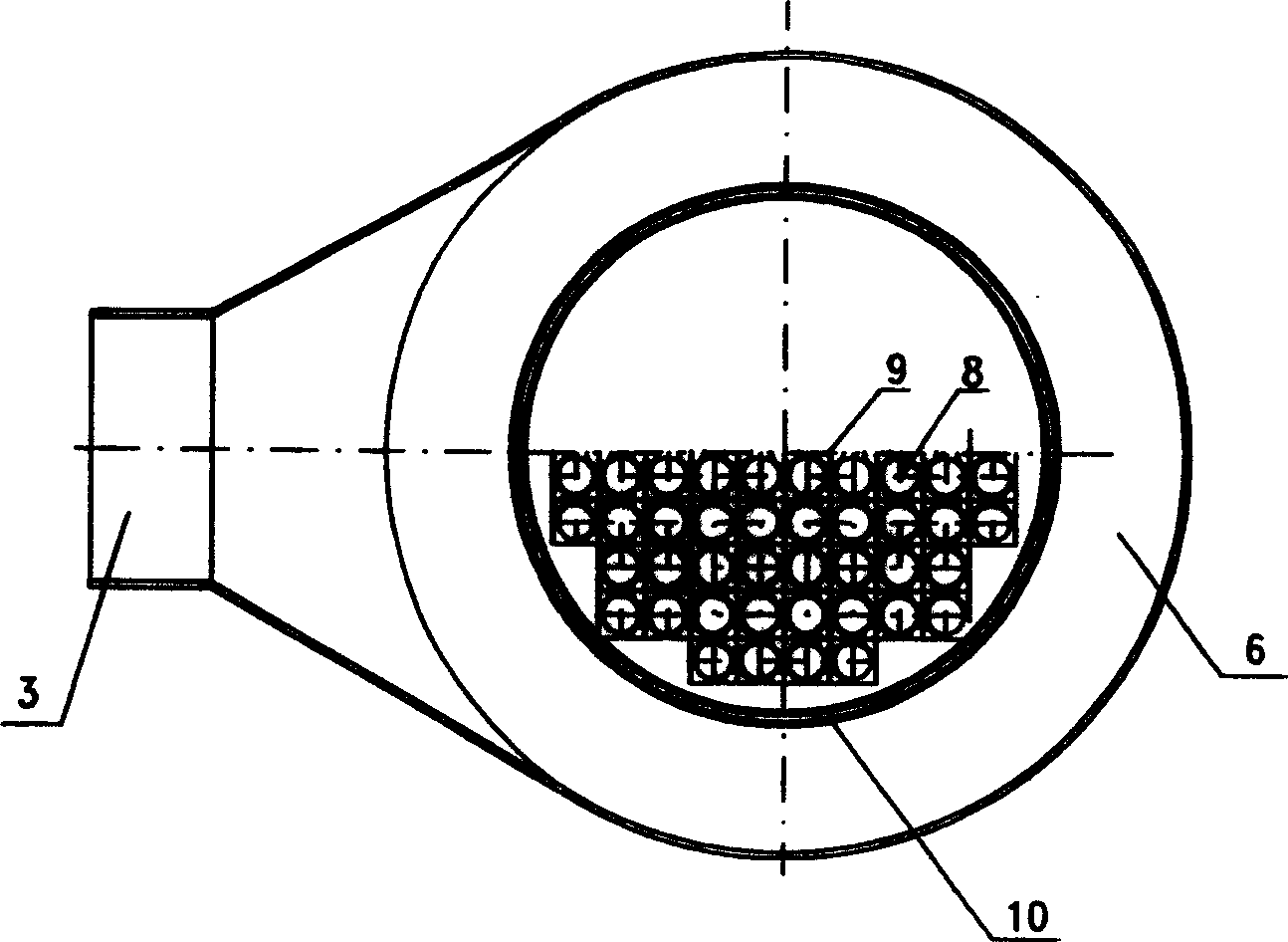

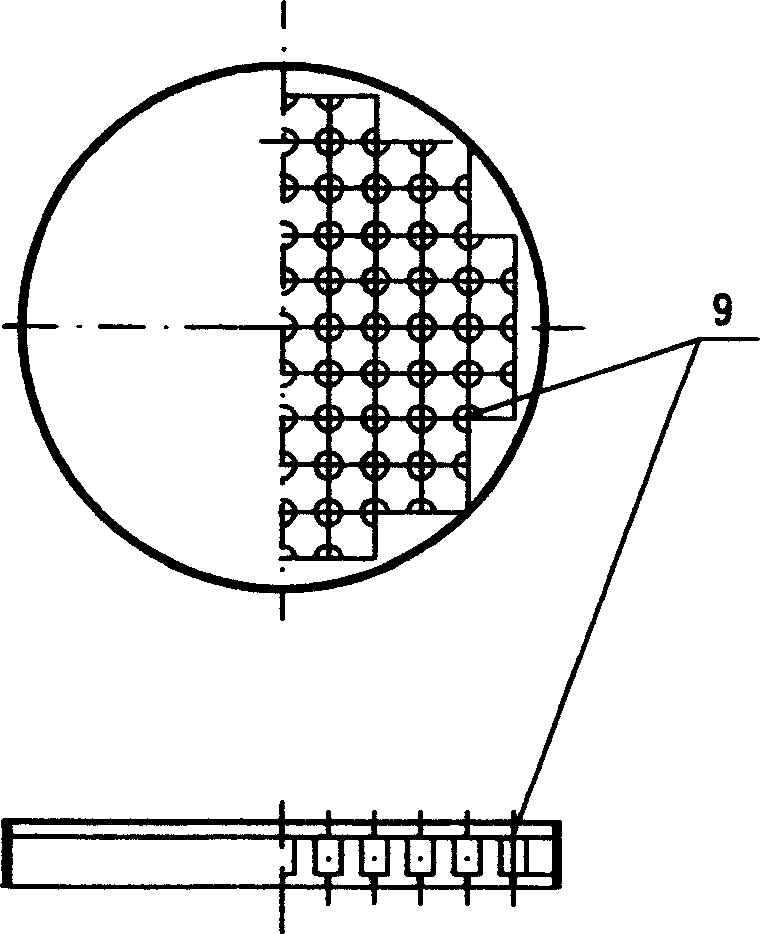

[0013] The present invention can be made of carbon steel or stainless steel and other metal materials, and can be processed by using general sheet metal technology, machining methods and equipment. Implement the present invention, as long as press Figure 1~4 As shown in the design, each part of the device is processed, and connected and assembled according to the interconnection relationship described in the above manual. figure 1 The flow channel structure shown can better implement the present invention. For example, the inventor recommends that the design consists of φ1000mm shell diameter, 6000mm shell length, φ1200mm inlet and outlet air ring sleeve diameter, 600mm inlet and outlet air ring sleeve length, and 150 φ51×3.5×6000mm rapid expansion and accelerated flow scaling tubes are evenly distributed in a square in the housing, 6 pieces of φ1000mm hollow ring mesh plates are evenly distributed in the axial direction among the rapidly expanding and accelerating flow scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com