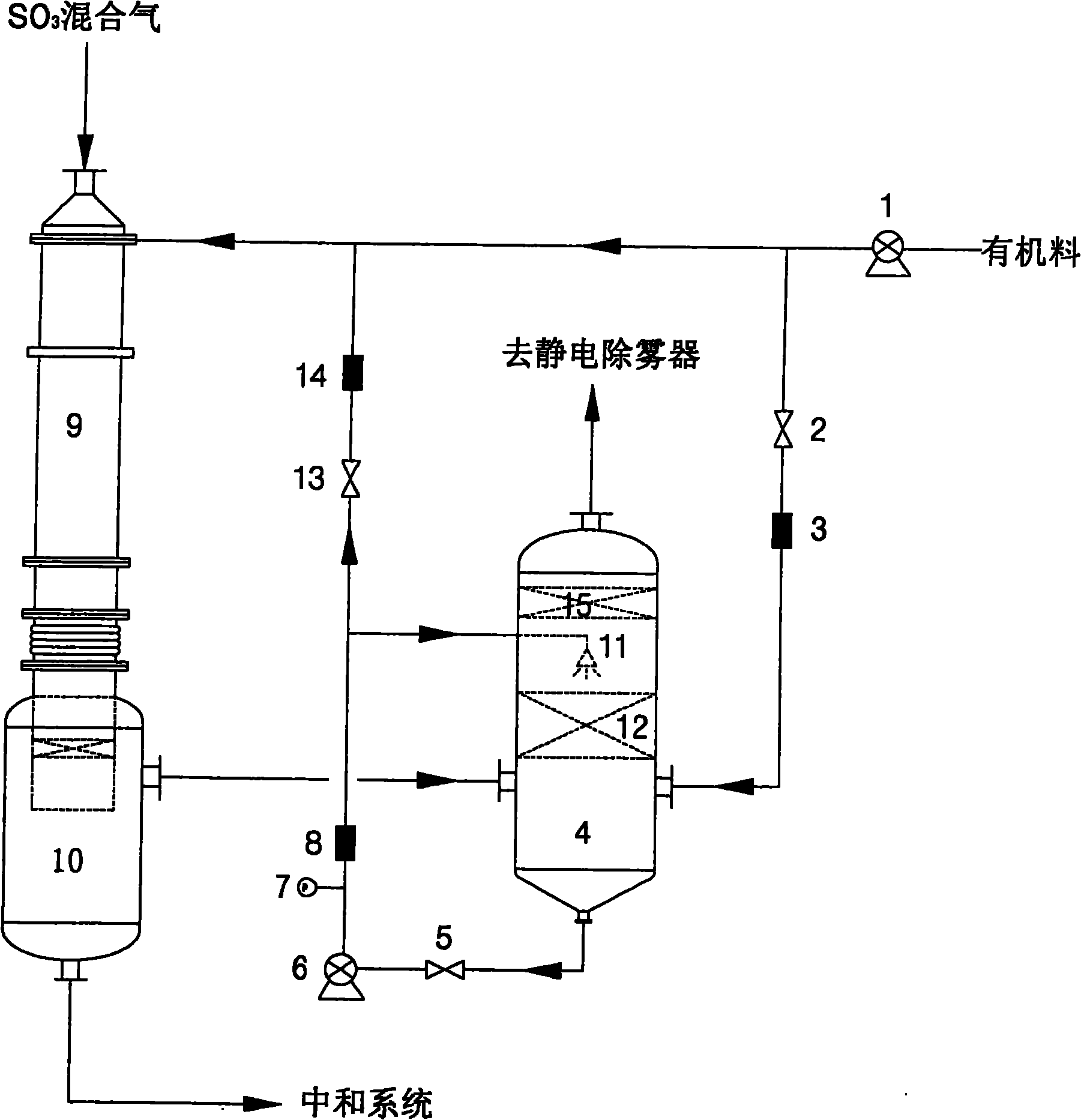

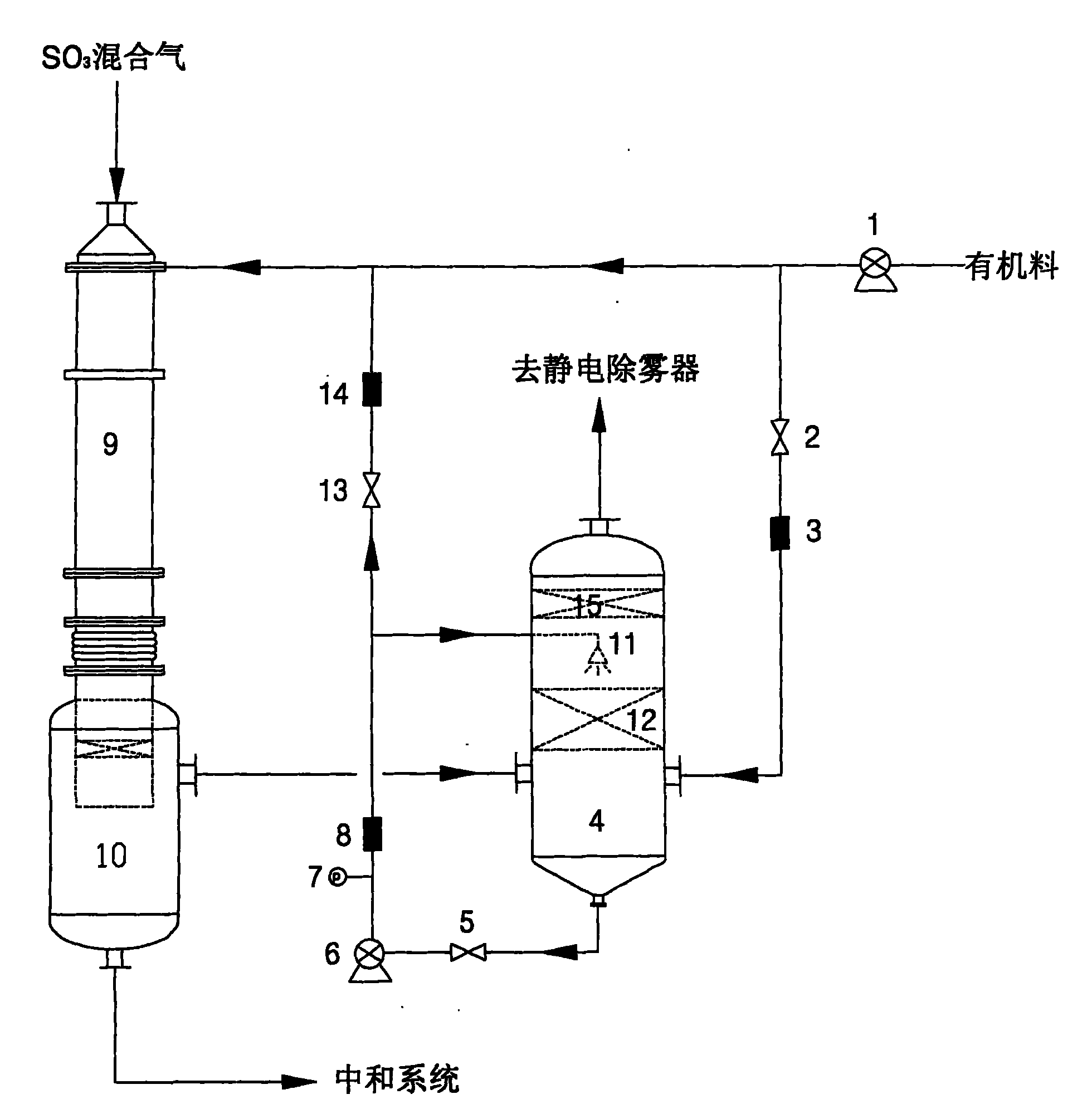

Sulfur trioxide tail gas treating device in sulfonation reaction

A technology of sulfur trioxide and sulfonation reaction, applied in chemical treatment of small raw hide/big raw hide/leather skin/fur, small raw hide/big raw hide/leather/fur treatment, application, etc., can solve the problem of waste of raw materials and achieve Reduce the production of waste acid, ensure the normal start and stop, and improve the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 3.8t / h Sulfonated Fatty Alcohol Polyoxyethylene Ether to Prepare SO in AES Production 3 Tail gas treatment: open the organic material (fatty alcohol polyoxyethylene ether) into the tail gas absorption tower valve 2 (the first valve), enter about 8% liquid level into the absorption tower 20, close the valve 2 after feeding, and open the bottom of the absorption tower Valve 5 (the third valve) starts the circulation pump 6, and the tail gas absorption tower circulates itself; adjust the outlet pressure of the circulation pump to 0.4MPa, and the circulation flow rate is 2.5t / h. SO from the gas-liquid separator 10 3 Tail gas reacts and absorbs with the organic material that is sprayed down in countercurrent. After 2 minutes of reaction, open the valve 13 (the second valve) of absorbing material into the sulfonator, and inject it into the sulfonator through the circulation pump to participate in the reaction together with fresh organic material. And adjust the flow rate to ...

Embodiment 2

[0035] 1.6t / h SO in the production of leather fatliquor from sulfonated rapeseed oil 3 Tail gas treatment: open the organic material (vegetable oil) into the tail gas absorption tower valve 2 (the first valve), enter about 6% liquid level into the absorption tower 20, close the valve 2 after feeding, and open the absorption tower bottom valve 5 (the third valve). valve), start the circulation pump 6, and the tail gas absorption tower itself circulates; adjust the outlet pressure of the circulation pump to 0.3MPa, and the circulation flow rate is 1.1t / h. SO from the gas-liquid separator 10 3Tail gas reacts and absorbs with the organic material sprayed down in the countercurrent. After reacting for 5 minutes, open the valve 13 (the second valve) of the absorption material into the sulfonator, and inject it into the sulfonator through the circulation pump 6 to participate in the reaction together with the fresh organic material. , and adjust the flow rate to be 100kg / h, open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com