Flue gas desulfurizing tower and flue gas desulfurization and wastewater treatment method

A desulfurization tower and flue gas technology, which is applied in the direction of gaseous effluent wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problem of many equipment, large floor area, and inability to upgrade and transform equipment and boiler space, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

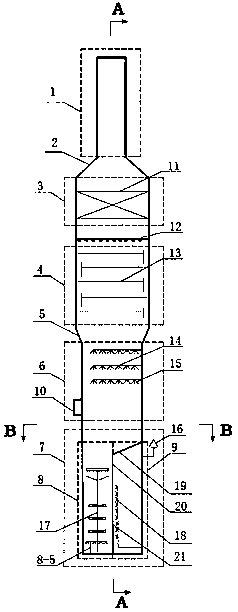

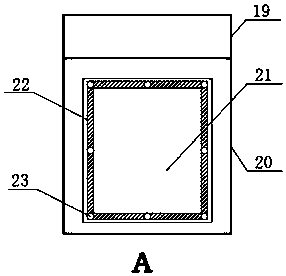

[0082] A flue gas dedusting and desulfurization tower, from top to bottom are the flue gas discharge area 1, the mist removal area 3, the tower area 4, the spray area 6 and the waste water treatment area 7, the flue gas discharge area 1 and the mist removal area 3 It is connected by a cone-shaped diameter 2, and below the demisting area 3 is a tray area 4, and the tray area 4 and the spray area 6 are connected by an inverted cone-shaped diameter 5, and below the spray area 6 is a waste water treatment area 7.

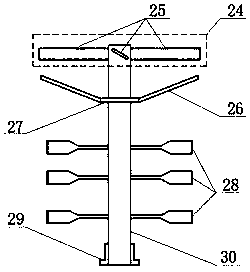

[0083] A wet electrostatic demister 11 is arranged in the demisting area 3, a liquid distributor 12 is arranged under the wet electrostatic demister 11, a tray area 4 is arranged under the liquid distributor 12, and a total of 4 layers of trays are arranged in the tray area 4. A sieve tray is selected; the spray area 6 is provided with three layers of spray pipelines 14, the distance between the spray pipelines 14 is 2m, and the atomizing nozzles 15 are evenly arranged o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com