Flue gas desulfurization and regeneration integral tower and flue gas desulfurization method

A flue gas, integrated technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as waste of water resources, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

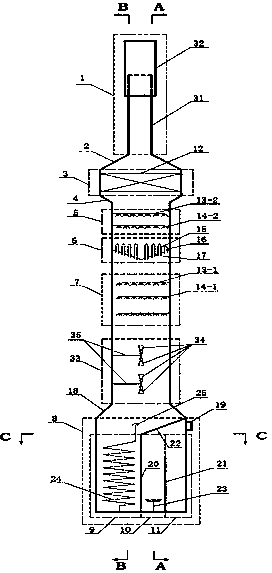

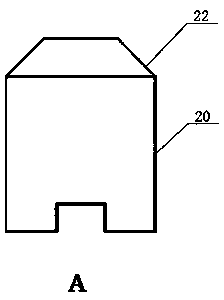

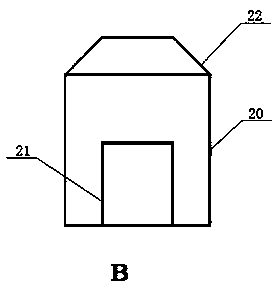

[0070] Flue gas desulfurization and regeneration integrated tower, from top to bottom are flue gas discharge area 1, defogging area 3, secondary spraying area 5, liquid holding tank area 6, primary spraying area 7, quenching and cooling area 33 and absorption The liquid regeneration area 8; the flue gas discharge area 1 and the demisting area 3 are preferably connected by a cone-shaped diameter 2, and the tower diameter ratio between the demisting area 3 and the flue gas discharge area 1 is 2.5~5; the demisting area 3 and the secondary The spray zone 5 is preferably connected by an inverted cone-shaped variable diameter 4, and the tower diameter ratio between the demister zone 3 and the secondary spray zone 5 is 1.5; the quenching cooling zone 33 and the absorption liquid regeneration zone 8 are preferably connected by a conical variable diameter 18 , The tower diameter ratio between the absorption liquid regeneration zone 8 and the rapid cooling cooling zone 33 is 1.5.

[007...

Embodiment 2

[0096] As a comparison, the flue gas desulfurization tower is not provided with an outer sleeve 32, and the rest is the same as that of Example 1, and the length of the "white smoke" at the chimney mouth is 60m.

Embodiment 3

[0098] As a comparison, close the valve on the clean water pipeline entering the rapid cooling cooling zone 33, and adjust the clean water flow to 0m 3 / h, all the other are the same as embodiment 1, and the content of soluble salt in the flue gas that enters chimney is 12.6mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com