Rectification method and apparatus for propylene and propane separation

A technology for propylene and propane, applied in the field of separation of propylene and propane, can solve the problems of low relative volatility and large energy consumption for separation, and achieve the effects of improving flux, improving separation efficiency, and optimizing radial distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

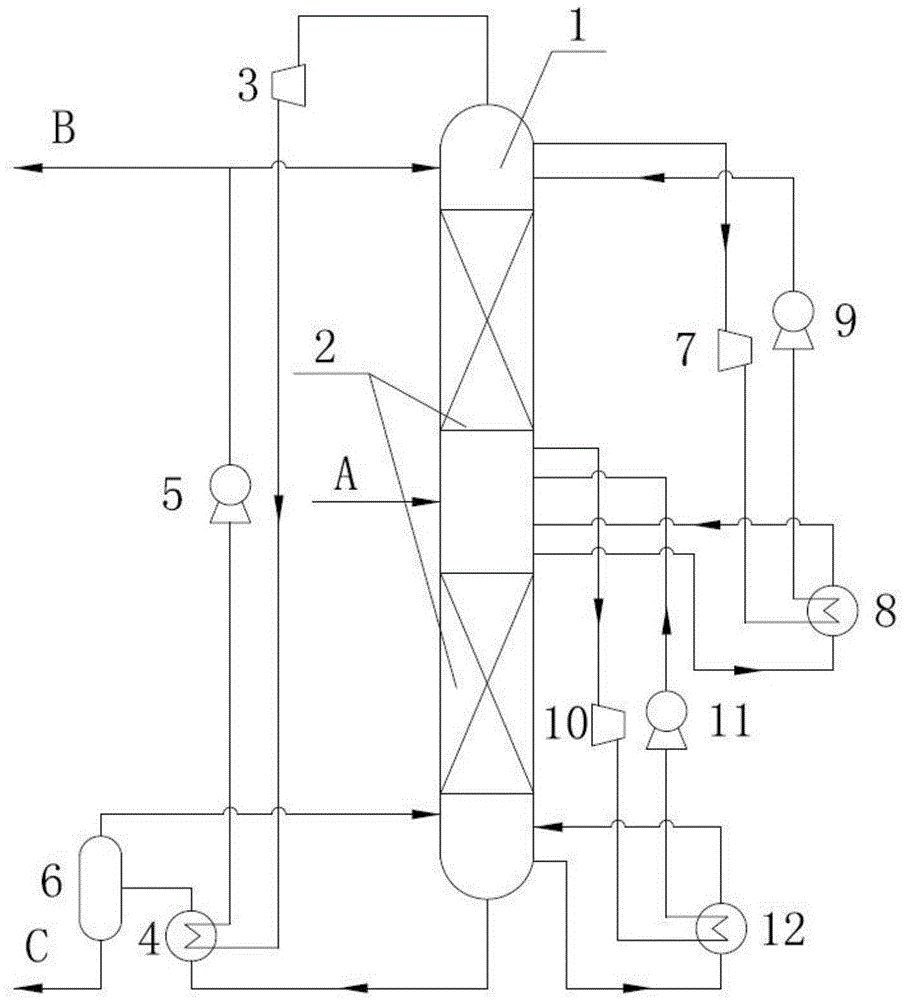

[0023] The liquefied hydrocarbon A enters the propane and propylene separation and rectification tower (1), and the gas phase stream at the top of the tower passes through the top stream compressor (3) to increase the pressure and temperature, and then enters the condensation reboiler heat exchanger (4) at the bottom of the tower to connect with the bottom of the tower. The liquid phase stream is subjected to heat exchange, and a part of it is refluxed into the top of the propane-propylene separation tower (1) through the pump (5), and a part is output as the product propylene B. After heat exchange, the liquid phase stream at the bottom of the tower is partially vaporized by heating, and enters the separation tank (6) of the stream stream in the bottom of the tower, and the gas phase fluid in the tank enters the bottom of the propane propylene separation and rectification tower (1) again, and the liquid phase is used as the product propane C. out. The rectification section an...

example 2

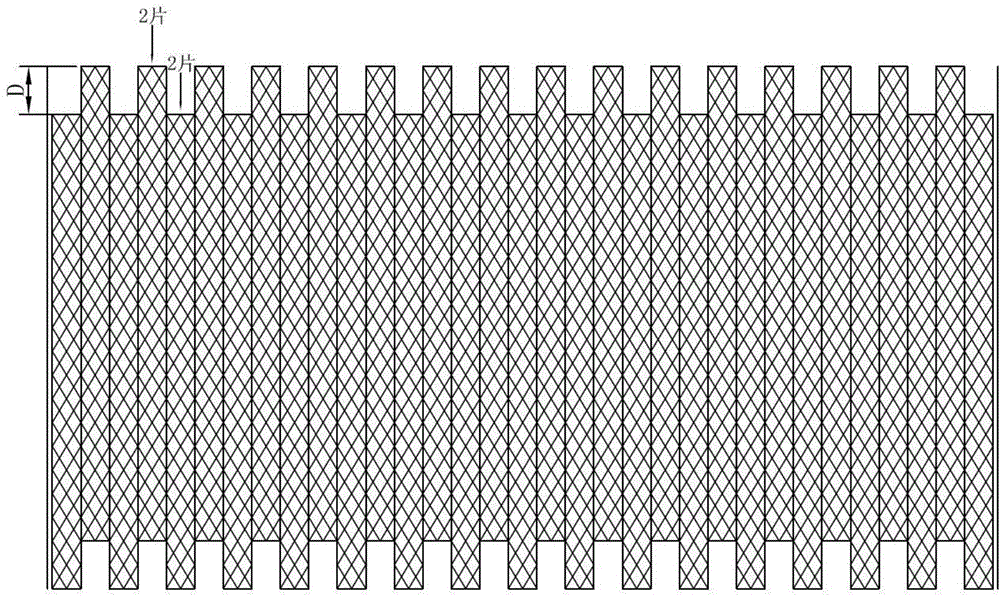

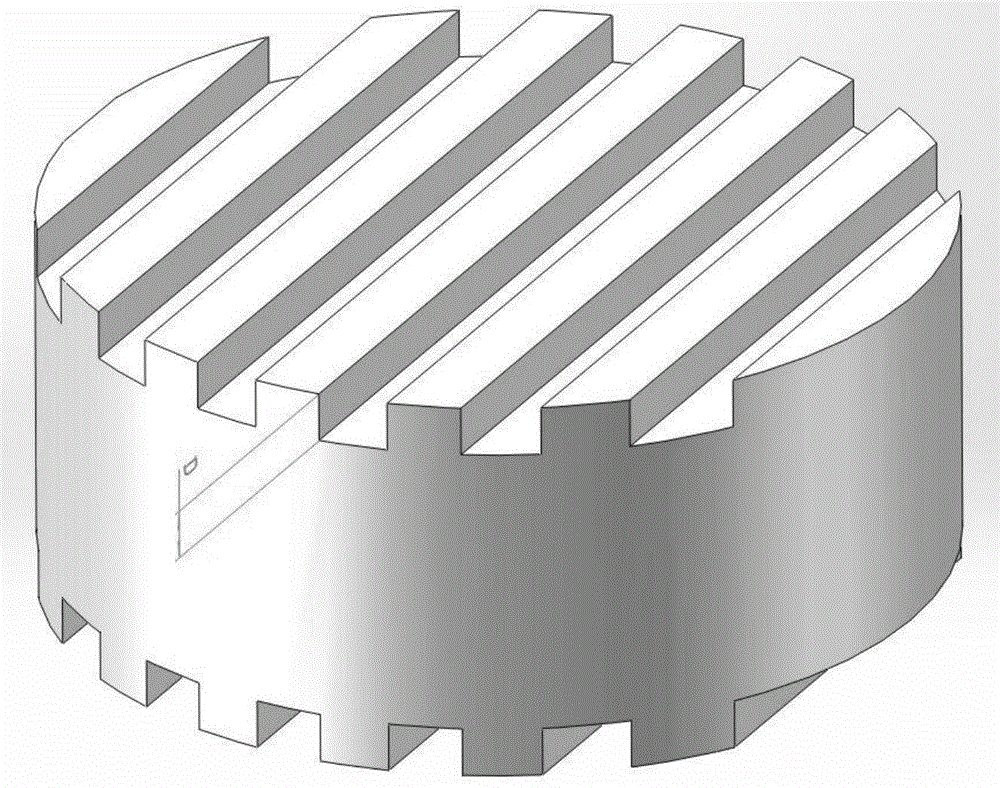

[0026] The propylene contained in the raw material liquefied hydrocarbon is 65% (mol), the height of the propane and propylene separation and rectification tower is 50m, the operating pressure is 1.8Mpa, and the operating temperature is 40°C. For the new type of staggered structured packing (4), every adjacent 10 pieces of packing is a group of packing units, and the difference between each group of packing units is the same height, which is 50% of the height of the packing unit. The propylene concentration at the top of the column is 99.7% (mol), and the propylene concentration at the bottom of the column is 2.6% (mol). Energy consumption is reduced by 30%.

example 3

[0028] The propylene contained in the raw material liquefied hydrocarbon is 70% (mol), the height of the propane and propylene separation and rectification tower is 100m, the operating pressure is 2.2Mpa, and the operating temperature is 50°C. For the new type of staggered structured packing (4), every adjacent 30 pieces of packing is a group of packing units, and the difference between each group of packing units is the same height, which is 75% of the height of the packing unit. The propylene concentration at the top of the column was 99.8% (mol), and the propylene concentration at the bottom of the column was 1.6% (mol). Energy consumption is reduced by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com