3D nanoflower-shaped MnCrOX-coated sepiolite low-temperature denitration catalyst and preparation method thereof

A low-temperature denitrification and sepiolite technology, applied in the field of flue gas denitrification, can solve the problems of difficult fixation of active components, complicated process preparation and high denitration temperature, and achieve the effects of enhancing redox capacity, simple process and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 5g of raw soil sepiolite in 150mL of H with a concentration of 1mol / L 2 SO 4 In the solution, stir and react for 4 hours at a speed of 300r / min, the purpose is to remove impurities, and at the same time move hydroxyl groups on the surface of sepiolite. After the reaction is finished, filter with suction, wash and dry, and use it as a carrier for future use.

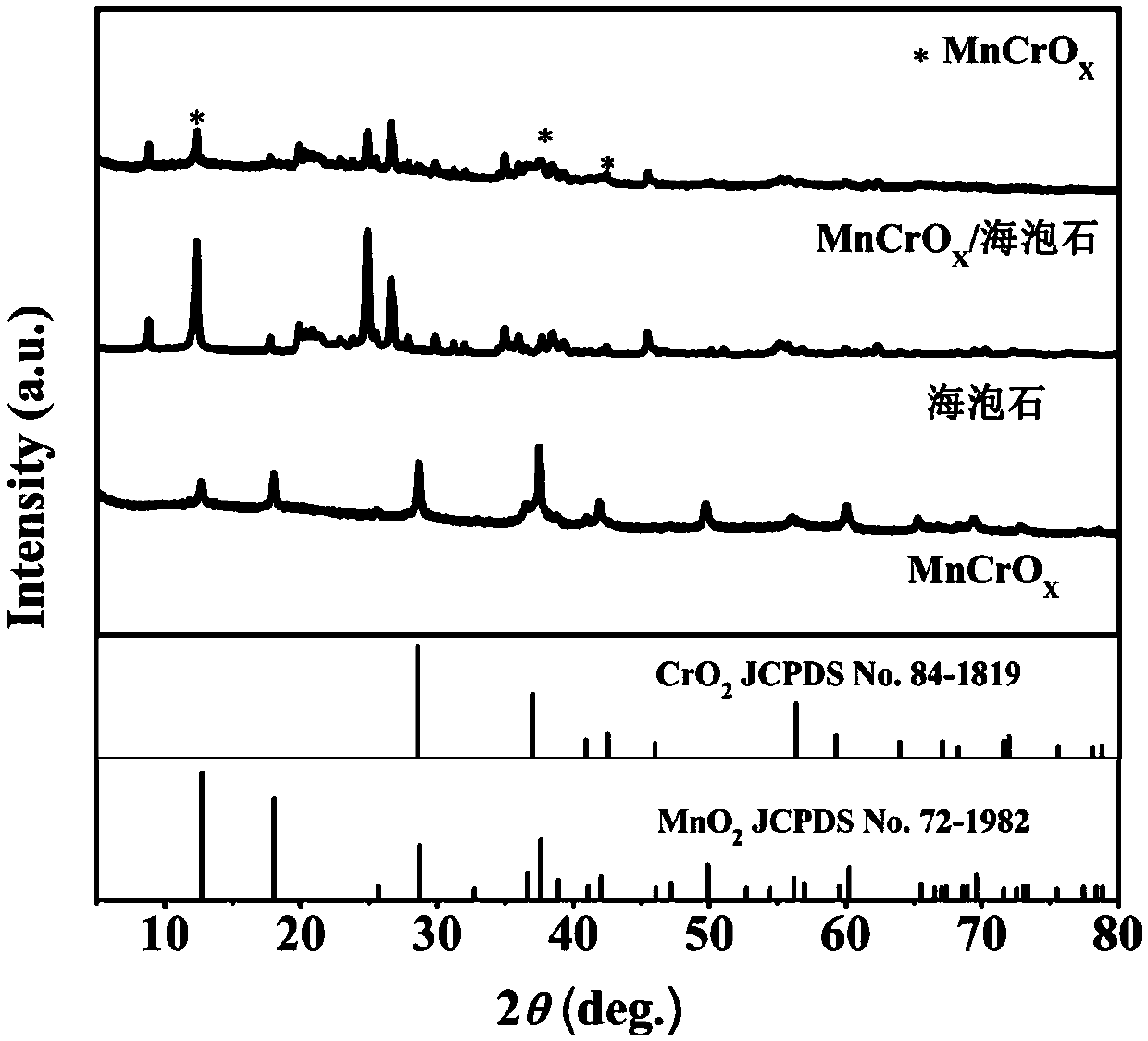

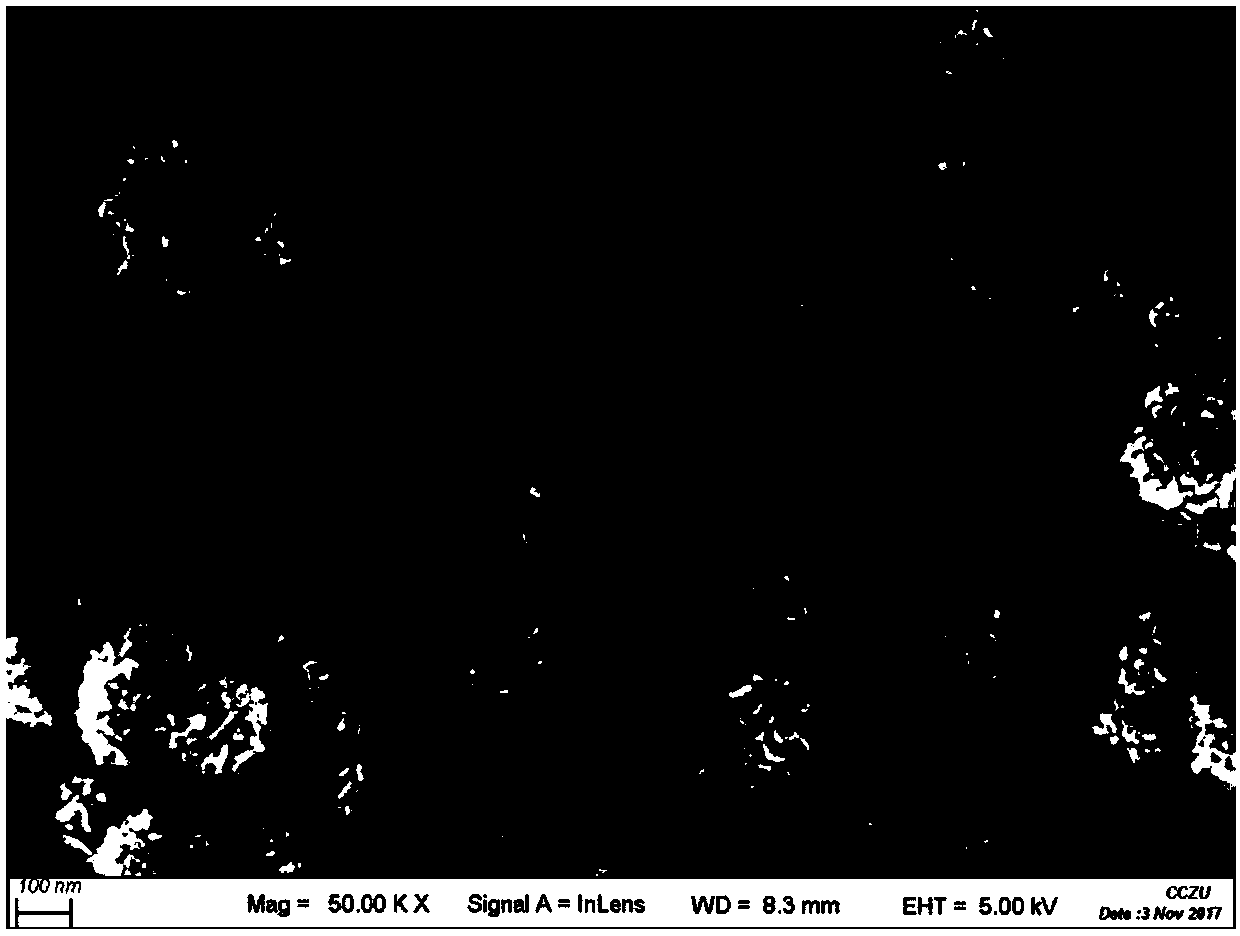

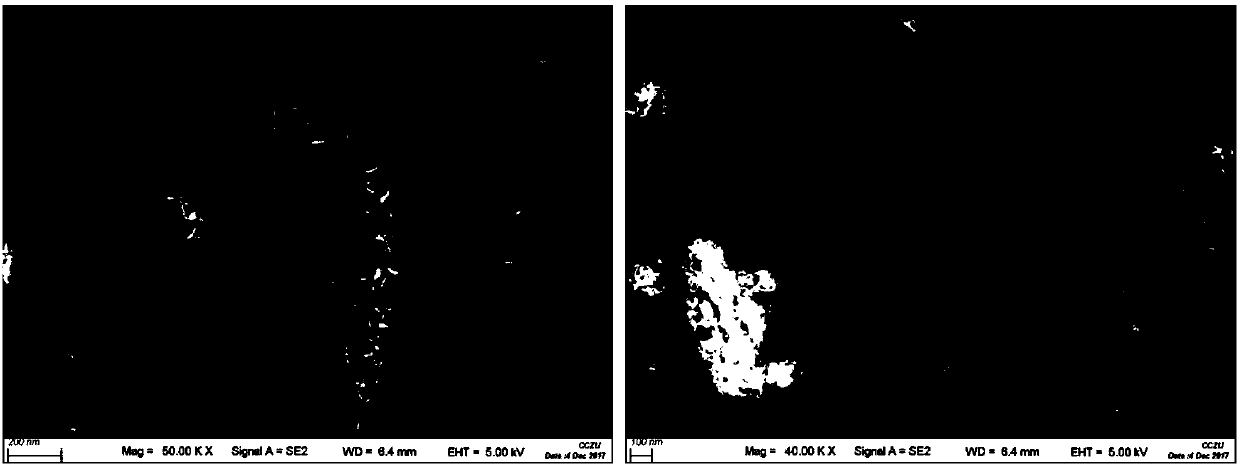

[0024] (2) Take 0.5 g of the carrier prepared in step 1, grind and sieve, disperse in 300 mL of deionized water, stir and sonicate for about 30 min. Take 0.80g of potassium permanganate and add it to the above-mentioned carrier, stir and dissolve until uniform. Dissolve 0.68g of chromium nitrate nonahydrate in 50mL of deionized water, and further add to the above mixed solution so that the pH value of the mixed solution is in the range of 1 to 3 (add glacial acetic acid to adjust if necessary), and stir at 80°C and 300r / min , condensed and refluxed for 4 hours, suction filtered after the reaction, w...

Embodiment 2

[0029] Similarly, 0.5 g of the sepiolite carrier prepared in step (1) of Example 1 was dispersed in 300 mL of deionized water, stirred and sonicated for about 30 min. Take 0.27g of potassium permanganate and add it to the above-mentioned carrier, stir and dissolve until uniform. Dissolve 0.68g of chromium nitrate nonahydrate in 50mL of deionized water, and further add to the above mixed solution so that the pH value of the mixed solution is in the range of 1 to 3 (add glacial acetic acid to adjust if necessary), and stir at 80°C and 300r / min , condensed and refluxed for 4 hours, suction filtered after the reaction, washed until neutral, dried at 60°C, and roasted at 350°C for 2 hours to obtain nano-flower-like MnCrO X (1:1) / sepiolite low temperature denitrification catalyst.

Embodiment 3

[0031] Similarly, 0.5 g of the sepiolite carrier prepared in step (1) of Example 1 was dispersed in 300 mL of deionized water, stirred and sonicated for about 30 min. Take 1.33g of potassium permanganate and add it to the above-mentioned carrier, stir and dissolve until uniform. Dissolve 0.68g of chromium nitrate nonahydrate in 50mL of deionized water, and further add to the above mixed solution so that the pH value of the mixed solution is in the range of 1 to 3 (add glacial acetic acid to adjust if necessary), and stir at 80°C and 300r / min , condensed and refluxed for 4 hours, suction filtered after the reaction, washed until neutral, dried at 60°C, and roasted at 350°C for 2 hours to obtain nano-flower-like MnCrO X (5:1) / sepiolite low temperature denitrification catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com