Preparation method and application of catalyst containing low-silicon composite metal Beta molecular sieve

A composite metal and molecular sieve technology, which is applied in the field of denitrification catalysts, can solve the problems of narrow high activity temperature range, achieve low cost, good denitrification effect, and improve denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

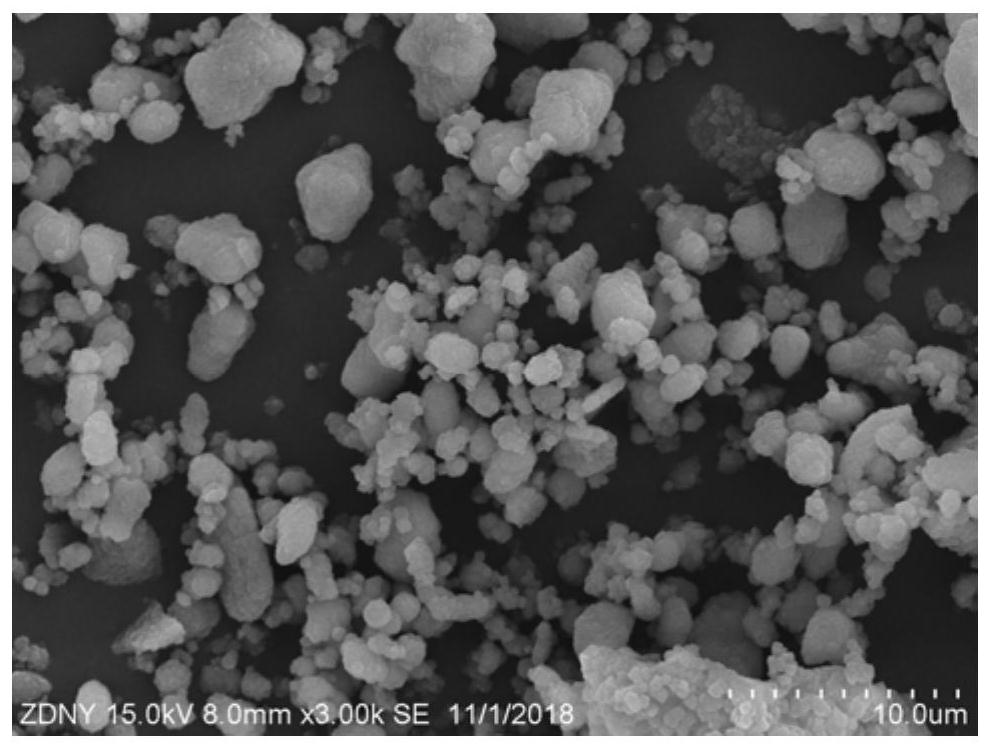

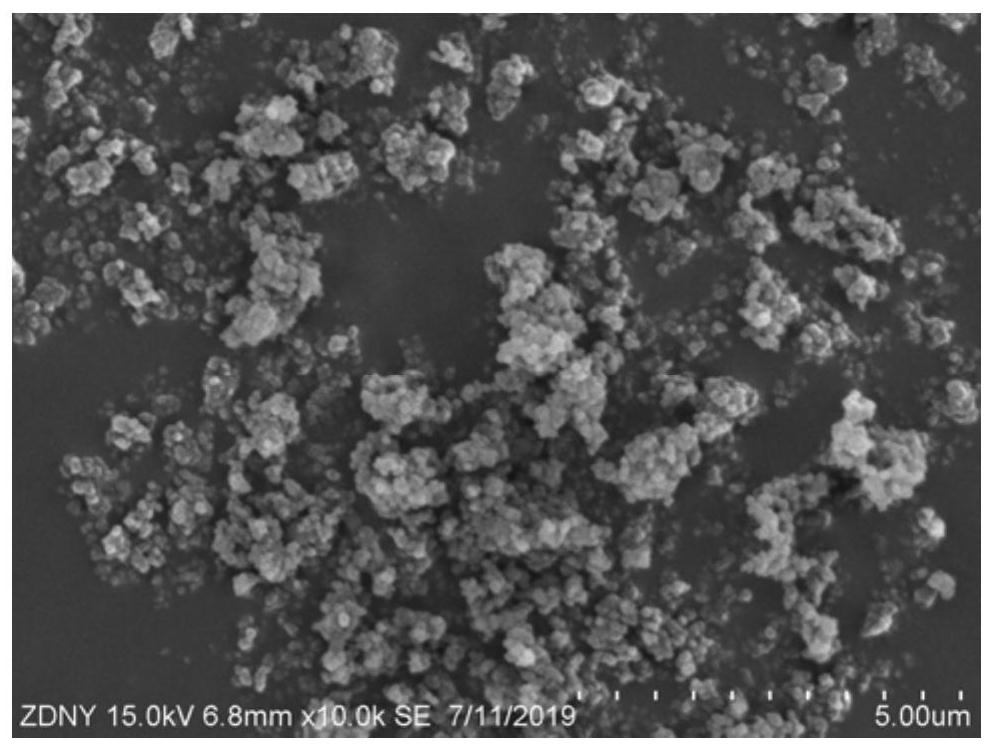

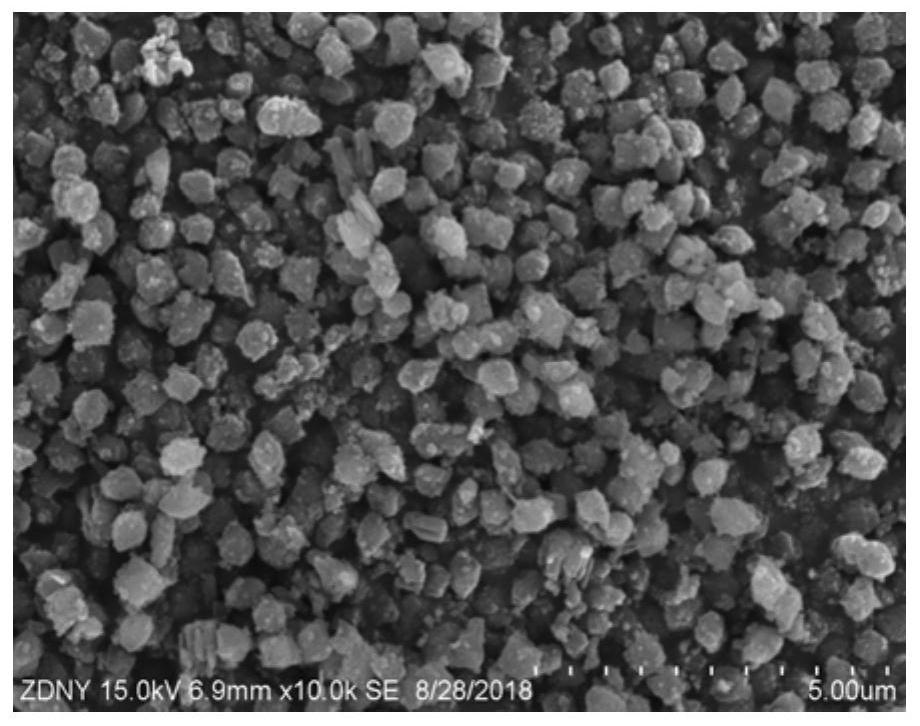

Image

Examples

Embodiment 1

[0034] S1, adding the roasted Beta molecular sieve to the prepared 10% sodium hydroxide solution, the liquid-solid mass ratio of the sodium hydroxide solution to the Beta molecular sieve is 30:1, after stirring and mixing, under the airtight condition of 100°C, Process 5h, the suspension liquid product that obtains is structure directing agent;

[0035] S2. Dissolve aluminum isopropoxide and sodium hydroxide in deionized water and stir evenly, then add silicon dioxide and stir well to form a silica-alumina gel, add ferrocene to the silica-alumina gel and stir After a certain period of time, a structure-directing agent of 5% of the total mass of the silica-alumina gel is added to obtain a mixed gel; the molar composition of the above-mentioned synthetic raw materials is silicon dioxide: aluminum isopropoxide: sodium hydroxide: ferrocene: H 2 O=12:1:5:0.2:150; after aging the mixed gel prepared above at 100°C for 2h, put it into a high-pressure reactor, raise the temperature to ...

Embodiment 2

[0040] S1, adding the roasted Beta molecular sieve to the prepared 10% sodium hydroxide solution, the liquid-solid mass ratio of the sodium hydroxide solution to the Beta molecular sieve is 20:1, after stirring and mixing, under the airtight condition of 100°C, Process 5h, the suspension liquid product that obtains is structure directing agent;

[0041] S2. Dissolve sodium metaaluminate and sodium hydroxide in deionized water and stir evenly, then add silica sol and stir well to form a silica-alumina gel, add ferrocene to the silica-alumina gel and stir for a while time, then add a structure-directing agent of 5% of the total mass of the silica-alumina gel dry basis to obtain a mixed gel; the molar composition of the above-mentioned synthetic raw materials is silica sol: sodium metaaluminate: sodium hydroxide: ferrous sulfate: H 2 O=20:1:6:0.3:180; after aging the mixed gel prepared above at 100°C for 2h, put it into a high-pressure reactor, raise the temperature to 160°C for ...

Embodiment 3

[0046] S1. Add the roasted Beta molecular sieve to the prepared 10% sodium hydroxide solution. The liquid-solid mass ratio of the sodium hydroxide solution to the Beta molecular sieve is 25:1. After stirring and mixing, under the airtight condition of 100°C, Process 5h, the suspension liquid product that obtains is structure directing agent;

[0047] S2. Dissolve pseudoboehmite and sodium hydroxide in deionized water and stir evenly, then add white carbon black and stir well to form a silica-alumina gel, add ferric nitrate to the silica-alumina gel and stir After a certain period of time, a structure-directing agent of 5% of the total mass of the silica-alumina gel is added to obtain a mixed gel; the molar composition of the above-mentioned synthetic raw materials is white carbon black: pseudoboehmite: sodium hydroxide: iron nitrate: H 2 O=25:1:15:0.5:180; after aging the mixed gel prepared above at 100°C for 2h, put it into a high-pressure reactor, raise the temperature to 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com