Fluent-based method for arranging selective non-catalytic reduction (SNCR) spray gun on circulating fluidized bed boiler

A circulating fluidized bed and spray gun technology, applied in the field of circulating fluidized bed SNCR, can solve the problems of ignoring combustion reaction and ignoring chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The present invention will now be explained in detail in conjunction with the embodiments and the drawings of the specification.

[0036] Such as Figure 5 As shown, the steps of an embodiment of the present invention are as follows:

[0037] Step 1. Import the physical model of the circulating fluidized bed boiler into the fluent, the physical model including the furnace, flue and separator connected in sequence.

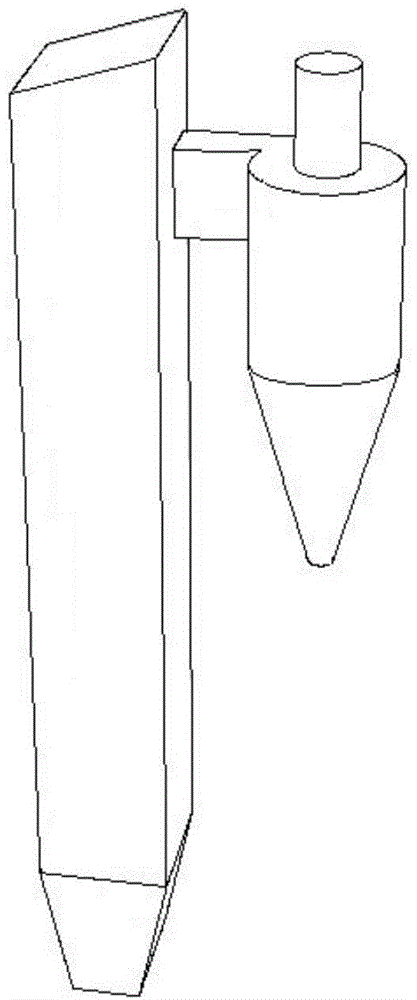

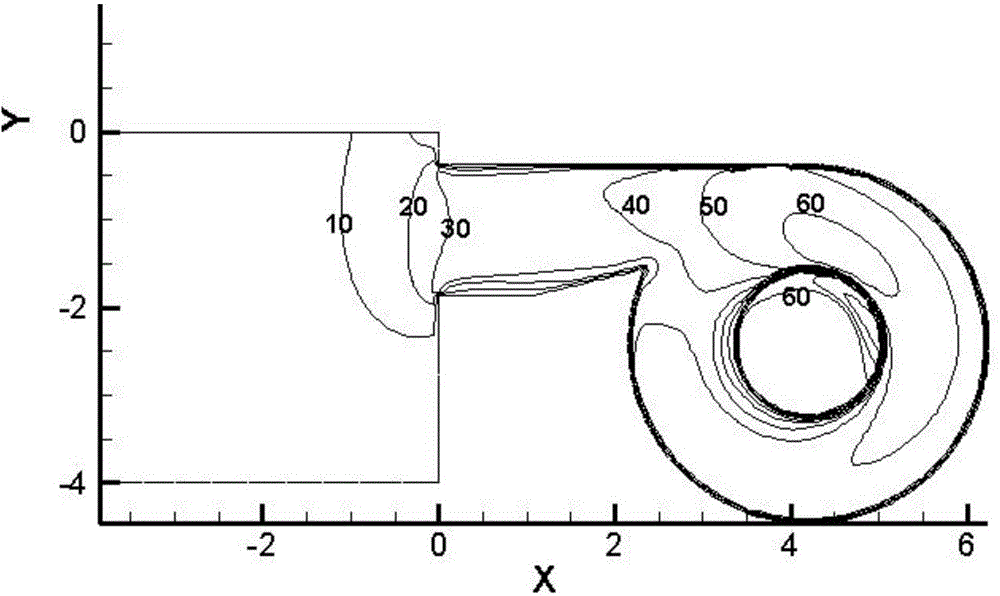

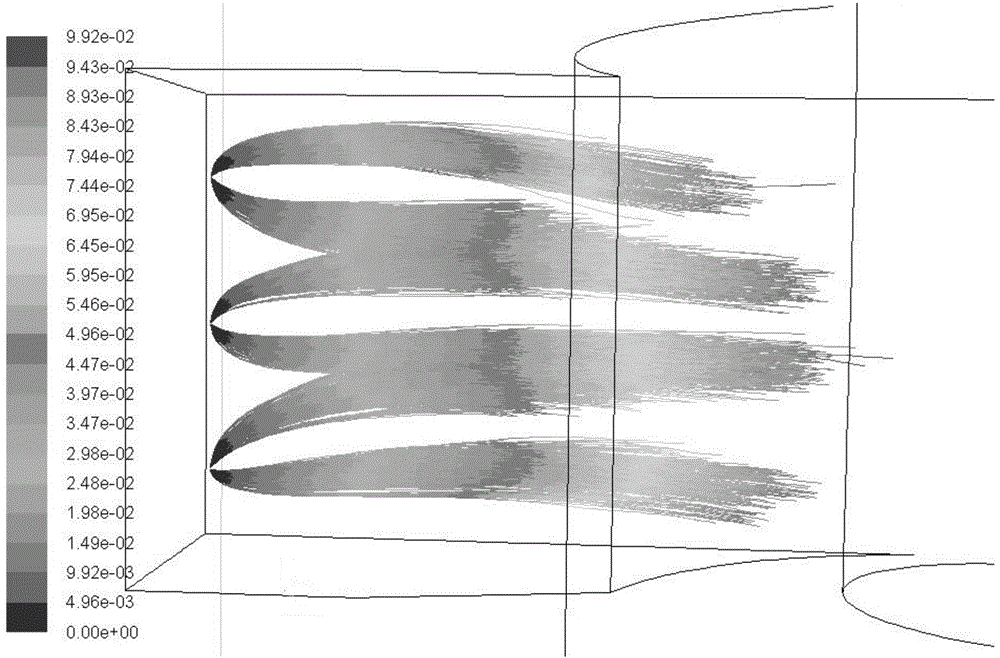

[0038] The physical model is pre-established, such as figure 1 As shown, the established physical model includes three calculation areas, which are sequentially connected to the furnace, furnace outlet flue, and cyclone separator (separator), and each calculation area is divided into grids. The flue at the outlet of the furnace is the place where spray guns are usually arranged, and the gas velocity is also relatively high. For the accuracy of calculation, the grid is finer, and the number of divisions is 2,800,000 to 3,200,000.

[0039] Step 2: Set boundary conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com