Low temperature SCR moving bed flue gas denitration method for coal-fired boiler

A coal-fired boiler and moving bed technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as difficulty in achieving sulfur resistance and water resistance, and achieve low space requirements, high denitration performance, and wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

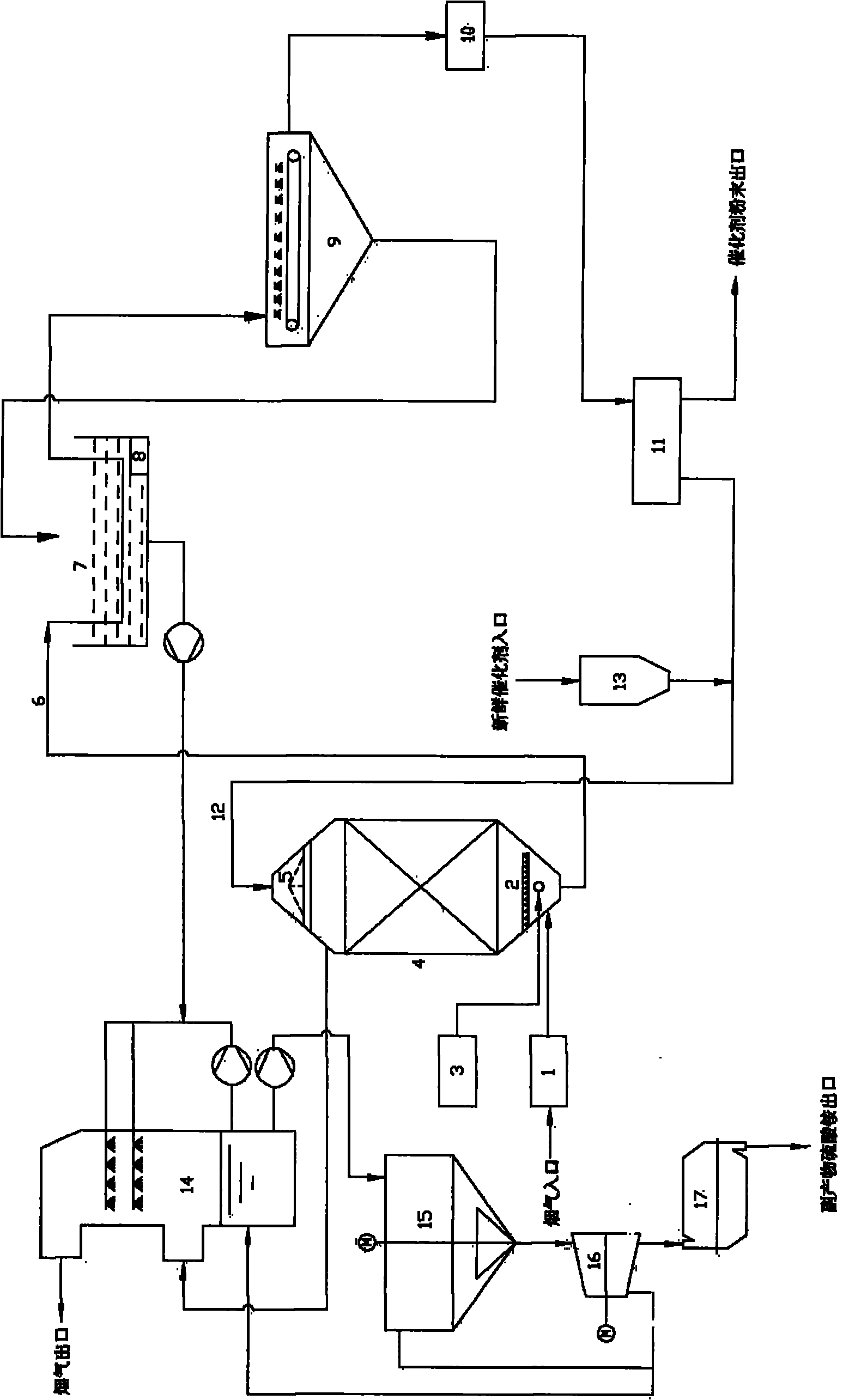

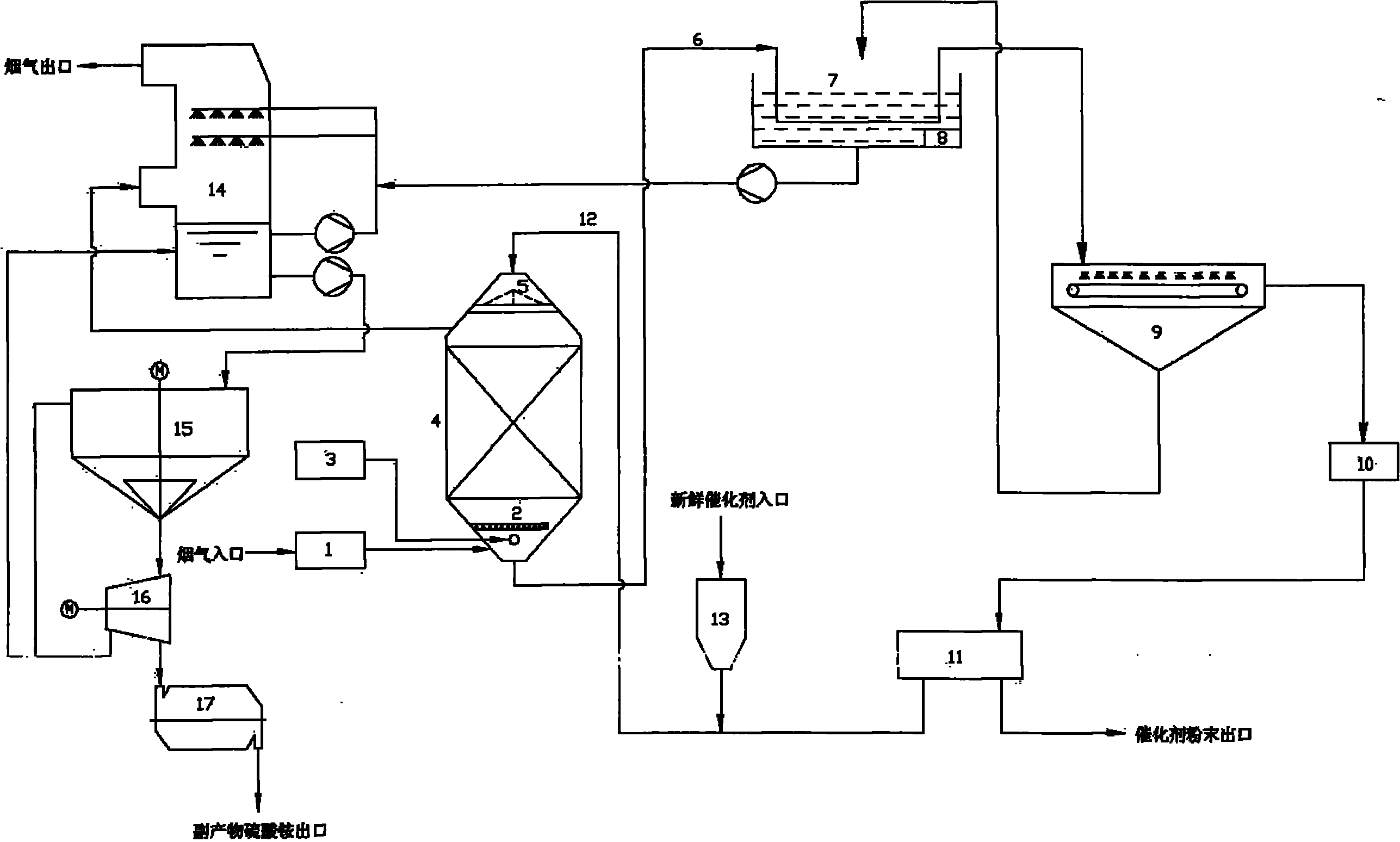

[0020] A power station boiler exhausts 500,000 m of flue gas 3 / h, the concentration of sulfur dioxide in the flue gas is 2000mg / Nm 3 , the concentration of nitrogen oxides is 600mg / Nm 3 , The design diameter of the denitrification reactor is 8 meters, the height is 20 meters, and the catalyst with a particle size of 2.5-7.5 mm is selected, and the total circulation is 200 tons. The specific process is:

[0021] The temperature of the flue gas from the boiler is 125°C. The flue gas enters the moving bed denitrification reactor 4 after passing through the dust collector 1, and 150 tons of granular catalysts are preset in the reactor; the flue gas passes through the gas distributor 2 and is connected with the ammonia generator 3 The ammonia gas is mixed and contacted, the added NH 3 The molar ratio of NOx to the flue gas is 1:1, and the mixture enters the catalytic layer together with the latter, and the flue gas from which NOx has been removed is discharged from the upper pa...

Embodiment 2

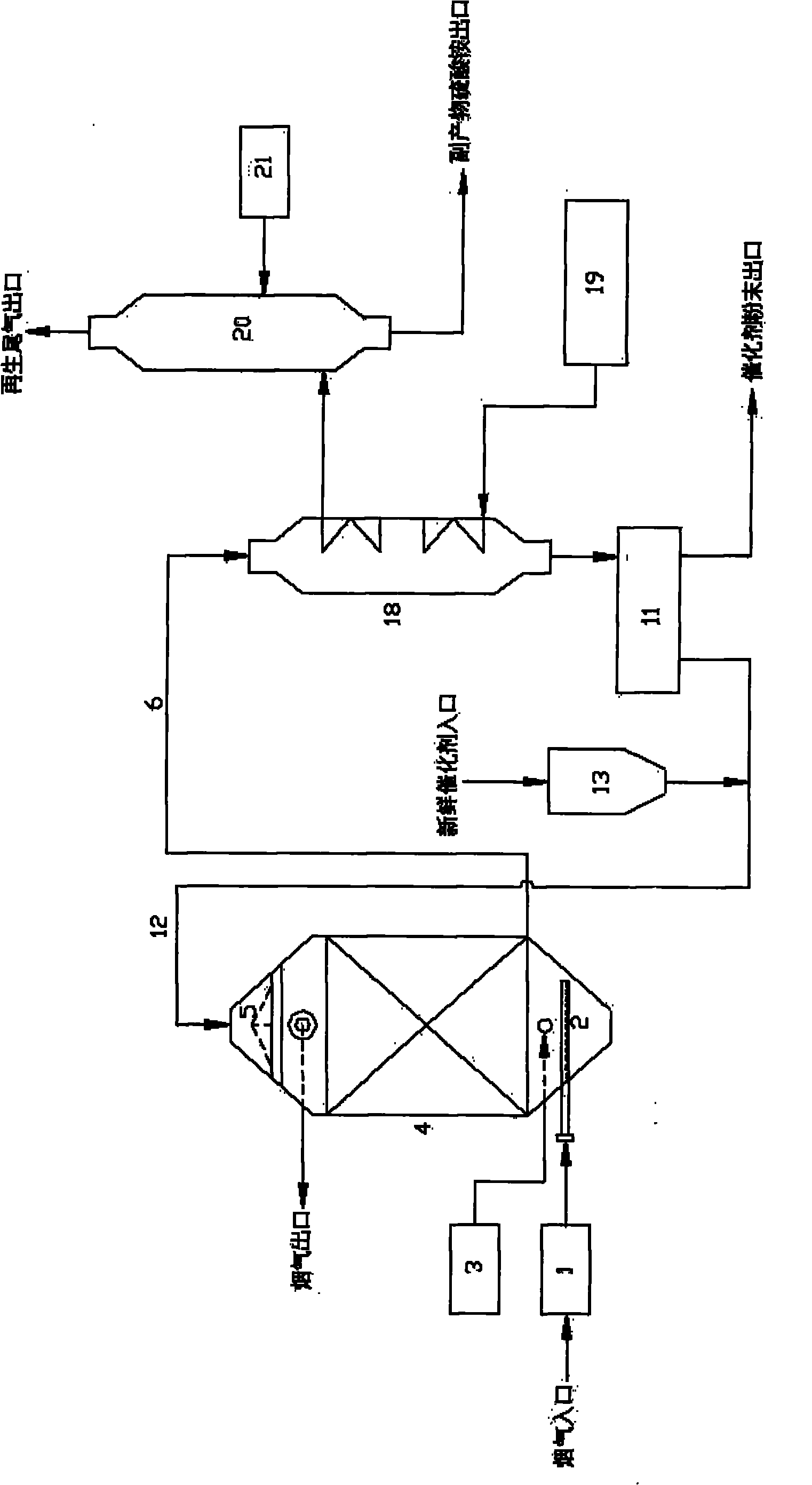

[0024] A power station boiler exhausts 1.2 million m3 of flue gas 3 / h, the concentration of sulfur dioxide in the flue gas is 1500mg / Nm 3 , the concentration of nitrogen oxides is 450mg / Nm 3 , The denitrification reactor is designed with a diameter of 10 meters and a height of 25 meters. The catalyst with a particle size of 2.5 to 7.5 mm is selected. The shape of the catalyst is granular, short columnar or honeycomb, etc. The total circulation is 400 tons. The specific process is:

[0025] Such as figure 2 , the flue gas temperature from the boiler is 130°C, the flue gas enters the moving bed denitrification reactor 4 after passing through the dust collector 1, and 300 tons of short columnar catalysts are preset therein. The flue gas passes through the gas distributor 2, mixes and contacts with the ammonia gas from the ammonia generator 3, and the added NH 3 The molar ratio to NO in the flue gas is 1:1. After mixing evenly, it enters the catalytic layer together, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com