Medium-high temperature SCR denitrification catalyst with effect of resisting alkali metal poisoning and preparation method of medium-high temperature SCR denitrification catalyst with effect of resisting alkali metal poisoning

A denitrification catalyst, medium and high temperature technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problem of insufficient anti-alkali metal poisoning performance, short catalyst service life, Complicated production process and other issues, to achieve good anti-alkali metal poisoning performance, easy operation, high denitrification activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A medium-high temperature SCR denitration catalyst with anti-alkali metal poisoning and a preparation method thereof, characterized in that it comprises the following steps:

[0036] 1) Prepare materials

[0037] Each component in the denitration catalyst and its mass percentage content: V 2 o 5 1%, WO 3 5%, CeO 2 10%, TiO 2 84%;

[0038] According to each component in the denitrification catalyst and its mass percentage content, calculate and weigh the mass of the required medicine;

[0039] Described medicine comprises ammonium metavanadate (NH 4 VO 3 ), ammonium tungstate ((NH 4 ) 10 h 2 (W 2 o 7 ) 6 ), cerium nitrate (Ce(NO 3 ) 3 ), titanium dioxide (TiO 2 ) and oxalic acid (H 2 C 2 o 4 2H 2 O);

[0040] The ratio of the amount of ammonium metavanadate to oxalic acid is 1:2;

[0041] 2) Preparation of impregnation solution

[0042] 2.1) Add 0.643 grams of ammonium metavanadate and 2.736 grams of ammonium tungstate weighed in step 1) into the c...

experiment example 1

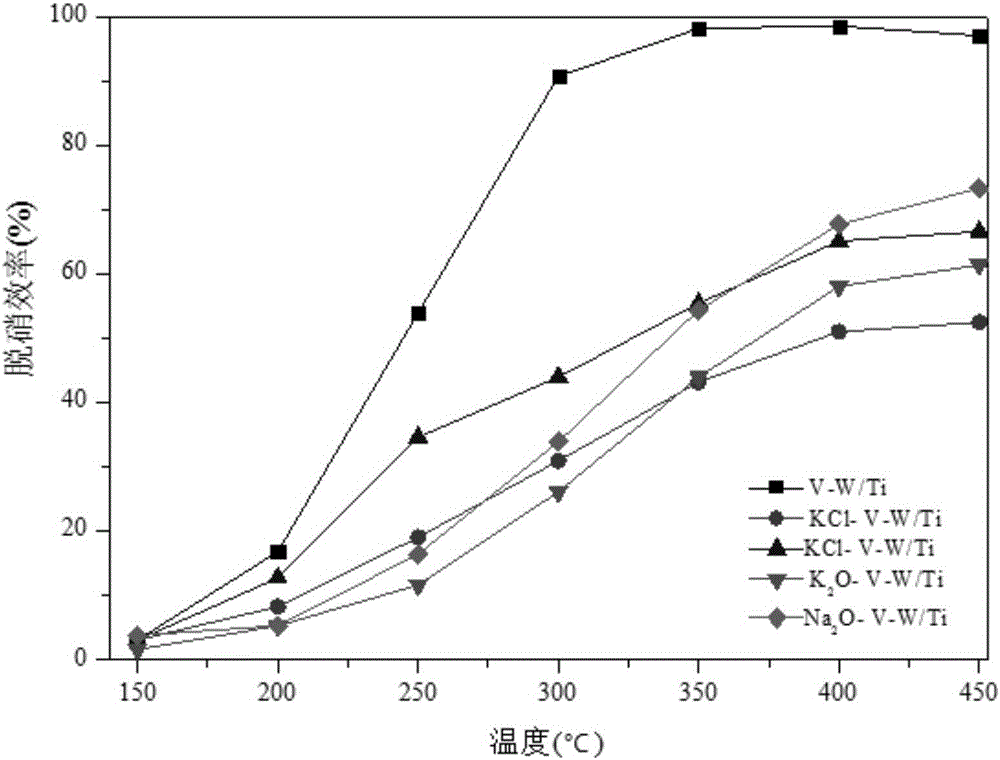

[0053] Carry out denitrification performance test to the catalyst sample prepared in the embodiment:

[0054] Take 0.2 g of the prepared catalyst and put it into a fixed bed quartz tube reactor for activity test. The reactor inlet contains 500ppm NO, 500ppm NH 3 , 3% O 2 , and the rest are N2. The total gas flow rate is 500mL / min, the space velocity is 150,000mL / g h, and the test reaction temperature is 150-450°C. The test data are as follows figure 2 shown.

experiment example 2

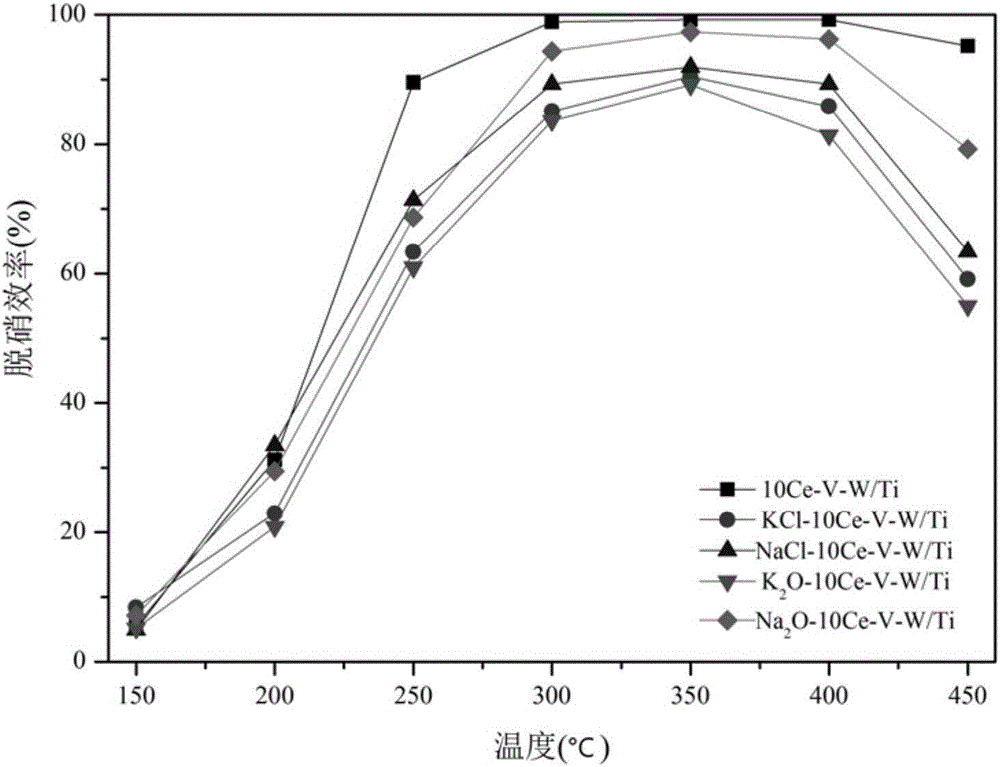

[0056] The catalyst sample prepared in the embodiment is carried out anti-alkali metal poisoning performance test:

[0057] The alkali metal is loaded into 5 g of the catalyst by the impregnation method, and the loading amount of the alkali metal is K / V or the ratio of the amount of Na / V substance is 4.

[0058] Weigh 0.083g KCl, 0.065g NaCl, 0.111g KNO according to the proportion 3 and 0.093 g NaNO 3 Dissolve in deionized water, then add 5 grams of catalyst powder ground to below 200 mesh, stir for 6 hours, and then dry at 105°C. The nitrate-loaded catalyst needs to be calcined at 450°C for 3 hours to obtain an alkali metal poisoning sample.

[0059] The poisoned sample was tested for denitrification activity, and it was found that the catalyst doped with Ce exhibited excellent anti-alkali metal poisoning performance, and the denitrification activity reached more than 80% at 300-400°C. Test data such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com