Catalyst for catalytic combustion of VOCs as well as preparation method and application thereof

A catalytic combustion and catalyst technology, applied in combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst poisoning, limited treatment effect, deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the VOCs catalytic combustion catalyst described in the above technical solution, comprising the following steps:

[0030] Mixing soluble cerium salt, titanyl sulfate and water to obtain a mixed solution;

[0031] Mix saturated ammonium carbonate solution with concentrated ammonia water to obtain a buffer solution;

[0032] Titrate the mixed solution and the buffer solution, adjust the pH value to 10.0-10.5, and then perform aging, drying and roasting in sequence to obtain TiO2 -CeO 2 composite oxides;

[0033] The TiO 2 -CeO 2 The composite oxide is soaked in sulfuric acid solution to obtain SO 4 2- / TiO 2 -CeO 2 Composite oxide carrier;

[0034] Put the SO 4 2- / TiO 2 -CeO 2 The composite oxide carrier was mixed with the active component precursor solution and then dried and calcined in sequence to obtain the active component / SO 4 2- / TiO 2 -CeO 2 Catalyst, described active component precursor...

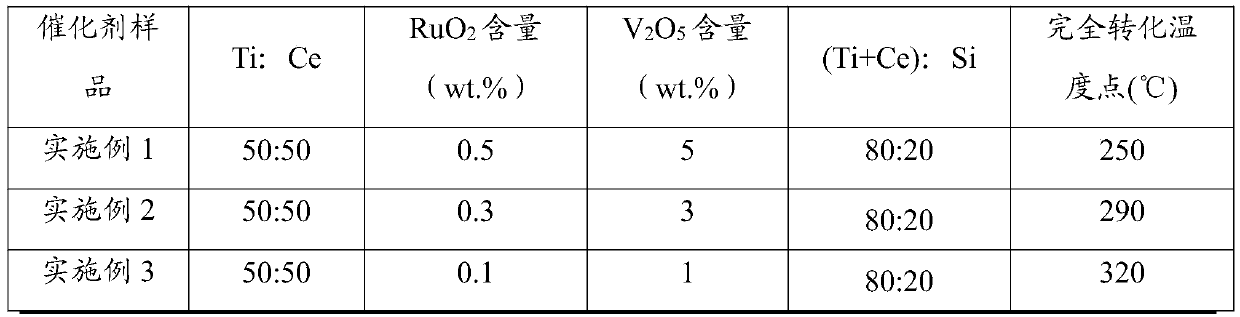

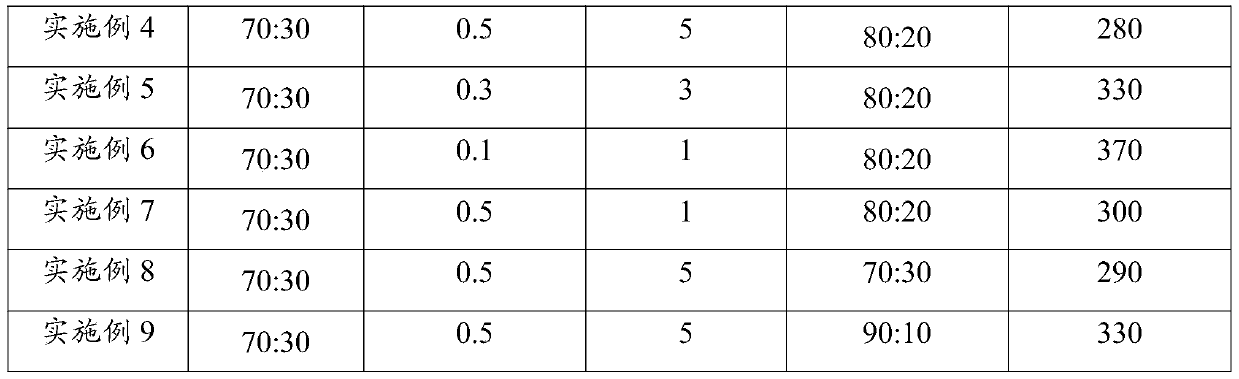

Embodiment 1

[0064] Weigh 7.73g of cerium nitrate and 3.02g of titanyl sulfate into a beaker of 100mL deionized water, and form a homogeneous solution A under vigorous stirring; another cup of mixed solution of saturated ammonium carbonate solution and concentrated ammonia water is prepared as buffer solution B; mix A and B The solution was titrated, and after the titration was completed, the pH value was adjusted to about 10 with concentrated ammonia water. After aging, filtering, drying and roasting, TiO can be obtained 2 -CeO 2 composite oxides. TiO 2 -CeO 2 The composite oxide was placed in 0.5mol / L H 2 SO 4 Soak in the solution for 12 hours at room temperature to obtain SO 4 2- / TiO 2 -CeO 2 support, ball milled to 20 μm, where TiO 2 The mass content is 50%, CeO 2 The mass content is 50%.

[0065] Containing noble metal active component RuCl by equal volume impregnation method 2 and transition metal promoter NH 4 VO 3 1mL of the mixed precursor solution, the SO 4 2- / ...

Embodiment 2

[0068] Weigh 7.76g of cerium nitrate and 3.03g of titanyl sulfate into a beaker of 100mL deionized water, and form a homogeneous solution A under vigorous stirring; prepare a cup of saturated ammonium carbonate solution and concentrated ammonia water mixed solution as buffer solution B; mix A and B The solution was titrated, and after the titration was completed, the pH value was adjusted to about 10 with concentrated ammonia water. After aging, filtering, drying and roasting, TiO can be obtained 2 -CeO 2 composite oxides. TiO 2 -CeO 2 The composite oxide was placed in 0.5mol / L H 2 SO 4 Soak in the solution for 12 hours at room temperature to obtain SO 4 2- / TiO 2 -CeO 2 support, ball milled to 30 μm, where TiO 2 The mass content is 50%, CeO 2 The mass content is 50%.

[0069] Containing noble metal active component RuCl by equal volume impregnation method 2 and transition metal promoter NH 4 VO 3 1mL of the mixed precursor solution, the SO 4 2- / TiO 2 -CeO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com