Catalyst for flue gas denitrification and preparation method of catalyst

A catalyst and denitrification technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of high initial installation cost and replacement cost of SCR catalyst, environmental and human damage, and catalyst loss To achieve excellent oxidation-reduction performance, improve comprehensive ability, and good anti-sulfur poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a catalyst for flue gas denitrification, comprising the following steps:

[0046] A) mixing soluble iron source, soluble cerium source, soluble nickel source, titanium dioxide and water, after dispersing, drying and grinding to obtain intermediate powder;

[0047] B) Calcining the intermediate powder obtained in the above steps and grinding again to obtain a catalyst for flue gas denitrification.

[0048] The selection range and optimization principles of the multi-component metal oxide nanomaterials in the present invention are consistent with the selection ranges and optimization principles of the aforementioned catalyst nanomaterials for flue gas denitrification, and will not be repeated here. repeat.

[0049] The invention firstly mixes soluble iron source, soluble cerium source, soluble nickel source, titanium dioxide and water, after dispersing, drying and grinding to obtain intermediate powder.

[0050]...

Embodiment 1

[0067] Preparation of Fe with a molar ratio of 2:2:1:10 2 o 3 -CeO 2 -NiO / TiO 2 Multi-element metal composite oxide

[0068] Dissolve 2.02g of ferric nitrate, 2.17g of cerium nitrate and 1.79g of nickel nitrate in 40mL of deionized water, add 2g of titanium dioxide powder, mix, stir vigorously for 1 hour, then ultrasonically mix for 5 hours, put it in an oven at 105°C for drying After 4 hours, after fully grinding, put it into a muffle furnace, calcinate at 550°C for 1.5 hours in an air atmosphere, and grind it into powder to obtain Fe 2 o 3 -CeO 2 -NiO / TiO 2 Multiple metal oxides.

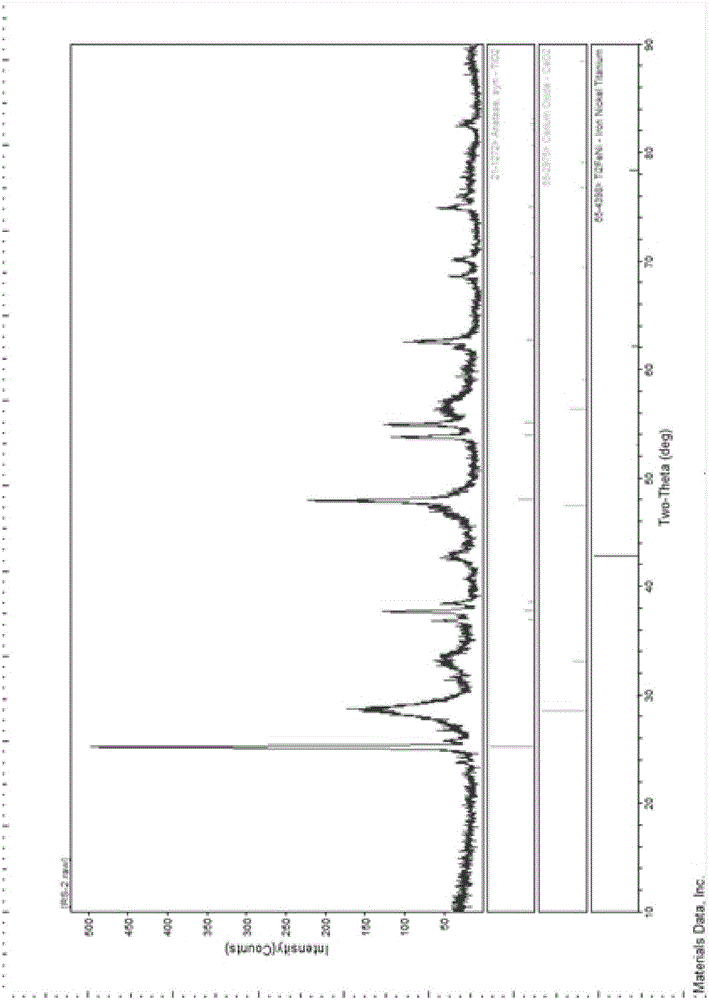

[0069] The multi-element metal oxide prepared in Example 1 of the present invention was characterized.

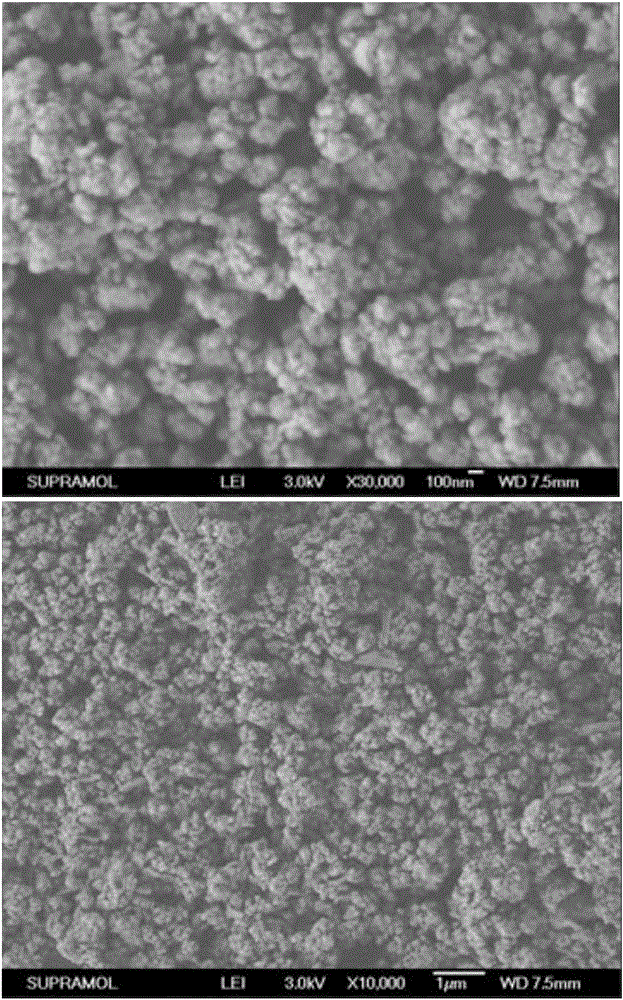

[0070] see figure 1 , figure 1 SEM electron micrograph of the multinary metal oxide powder prepared in Example 1 of the present invention.

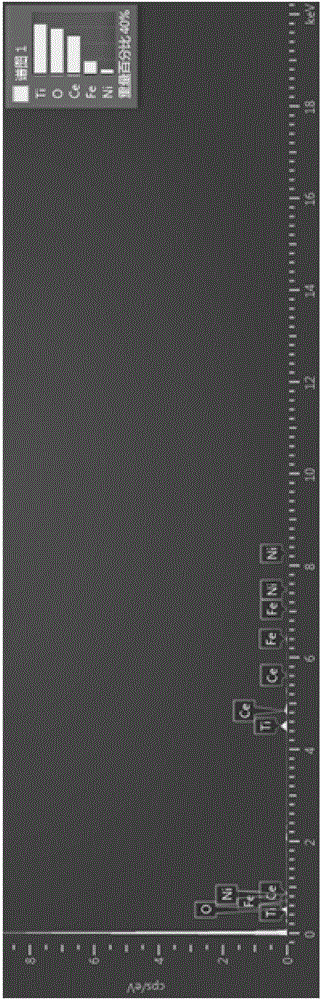

[0071] see figure 2 , figure 2 EDS energy spectrum of the multinary metal oxide powder prepared in Example 1 of the present invention.

[...

Embodiment 2

[0085] Preparation of Fe with a molar ratio of 0.5:0.1:4:10 2 o 3 -CeO 2 -NiO / TiO 2 Multiple metal oxides

[0086] Dissolve 0.169g of ferric chloride, 0.081g of cerium chloride and 2.56g of nickel chloride in 30mL of deionized water, add 1g of titanium dioxide powder, mix, stir vigorously for 2 hours, then ultrasonically mix for 3 hours, put in an oven at 95°C The seeds were dried for 6 hours, fully ground, put into a muffle furnace, calcined at 450°C for 1 hour in an air atmosphere, and ground into powder to obtain Fe 2 o 3 -CeO 2 -NiO / TiO 2 Multiple metal oxides.

[0087] The application detection of the multi-component metal oxide nanomaterial prepared in Example 2 of the present invention was carried out.

[0088] Method is with embodiment 1.

[0089] It can be seen from the test results that the multi-element metal oxide prepared by the present invention basically exhibits good anti-SO 2 and H 2 O poisoning ability. Especially above 250°C, due to the higher ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com