Process for recovery and purification of nitrous oxide from nitrous oxide-containing gas mixture

A technology of nitrous oxide and gas mixture, which is applied in the fields of nitrous oxide, nitrous oxide capture, chemical instruments and methods, etc., which can solve the problems of low recovery rate and achieve the effect of reducing greenhouse gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

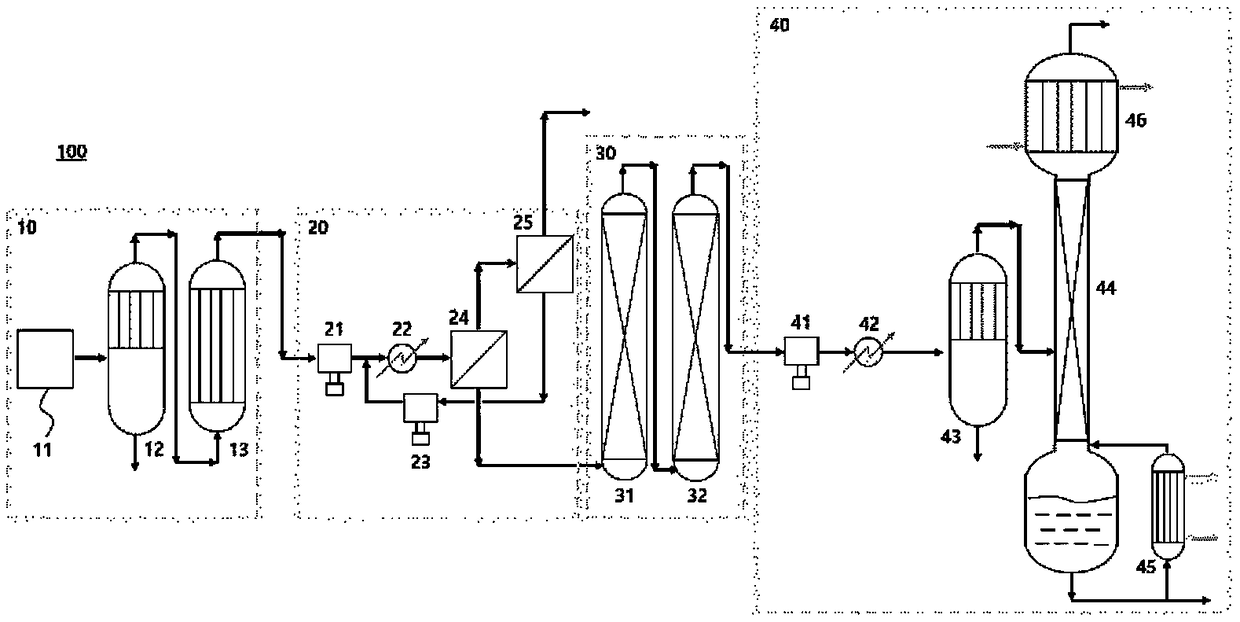

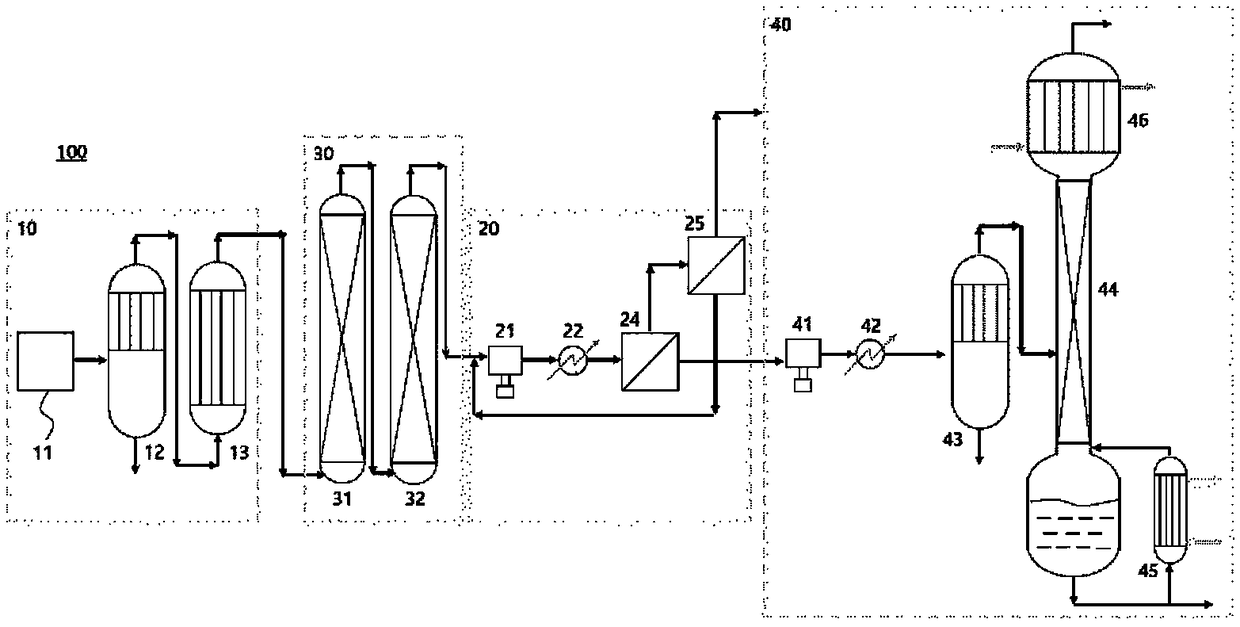

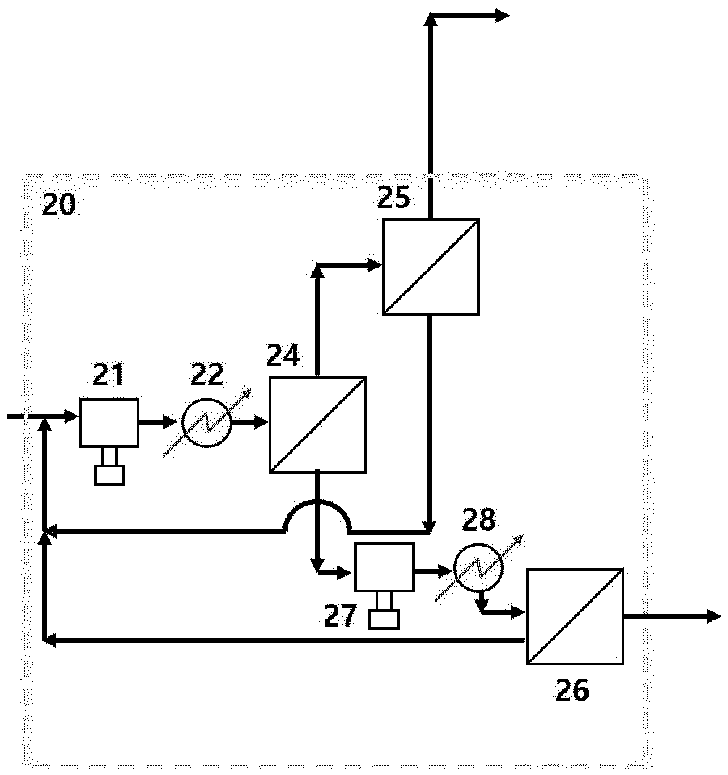

[0096] Such as figure 1 Shown, the recovery and purification method of nitrous oxide carried out in the present invention is the recovery and purification method of intermediate plant scale. Specific method reference for the method of recovering and purifying nitrous oxide from waste gas produced in the production process of adipic acid figure 1 A detailed description.

[0097] (1) Pretreatment process: In the pretreatment process (10), the waste gas produced in the adipic acid production process is supplied through the supply device (11), and then removed in the first flocculator (12) and filter device (13) Moisture, fine oil droplets and dust contained in the exhaust gas. The above-mentioned first flocculator is equipped with a 200-mesh stainless steel mesh with a thickness of 20 cm. The stainless steel mesh has a diameter of 30 cm and a length of 60 cm. The filter unit described above was equipped with a bag filter made of polyester material. The bag filter has a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com