System and method for co-processing N2O and VOC in caprolactam production waste gas

A technology of synergistic processing and caprolactam, which is applied in the production of caprolactam, gas treatment, adipic acid production, etc., can solve the problems of increasing the production and operation costs of enterprises, reducing safety, and easily causing explosions, so as to save production and operation costs and make it easy to obtain The effect of long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

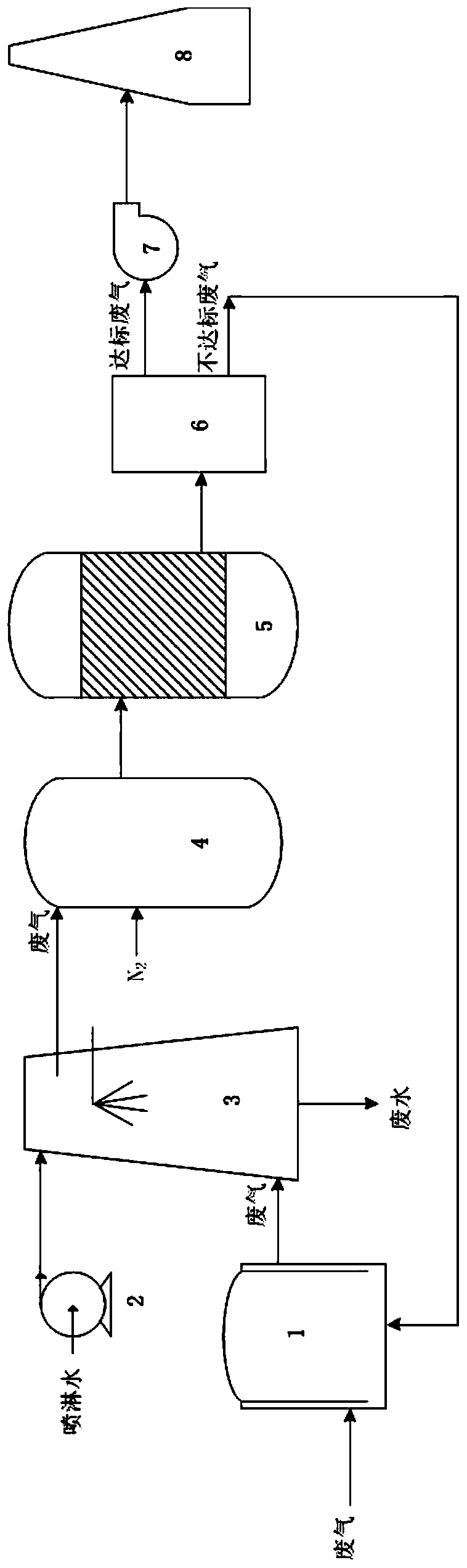

[0059] A kind of N in the waste gas of caprolactam production 2 O and VOC co-processing system, as attached figure 1 As shown, the system includes a gas storage device 1 , a water pump 2 , a water washing device 3 , an air bag 4 , a catalytic reaction device 5 , an online flue gas monitoring device 6 , an induced draft fan 7 and a chimney 8 . The waste gas from caprolactam production enters the gas storage device 1 for buffering, and enters the water washing device 3 from bottom to top. At the same time, the spray water enters from the top of the water washing device 3 through the water pump 2. The tert-butanol in the waste gas is condensed and absorbed, and is discharged from the water washing device along with the waste water. The bottom of 3 is discharged, the exhaust gas continues to pass into the air bag 4, and the N 2 Dilute the exhaust gas to reduce N in the exhaust gas 2 The concentration of O, the pretreated exhaust gas enters the catalytic reaction device 5, under ...

Embodiment 2

[0061] Use as attached figure 1 The system shown, for N in caprolactam off-gas 2 The processing method steps of O and VOC are as follows:

[0062] (1) Pretreatment: The waste gas from the production of caprolactam enters the spray washing tower, and the flow rate of the waste gas is 8000m 3 / h, the concentration of tert-butanol in the exhaust gas is 10000mg / m 3 , N in exhaust gas 2 The concentration of O is 300,000ppm, the temperature in the washing tower is 20°C, and the flow rate of spray water is 5t / h. Part of the tert-butanol in the treated waste gas is condensed and absorbed, and is discharged to the corresponding water treatment unit along with the waste water. Exhaust gas passes through N 2 Diluted, N 2 The volume concentration of O is reduced to 60500ppm, and the concentration of tert-butanol in the exhaust gas after pretreatment is 2000mg / m 3 ;

[0063] (2) Catalytic reaction: The pretreated exhaust gas enters the 2-stage adiabatic fixed-bed catalytic reactor, ...

Embodiment 3

[0066] Use as attached figure 1 The system shown, for N in caprolactam off-gas 2 The processing method steps of O and VOC are as follows:

[0067] (1) Pretreatment: The waste gas from the production of caprolactam enters the spray washing tower, and the flow rate of the waste gas is 8000m 3 / h, the concentration of tert-butanol in the exhaust gas is 10000mg / m 3 , N in exhaust gas 2 The concentration of O is 300,000ppm, the temperature in the washing tower is 20°C, and the flow rate of spray water is 6t / h. Part of the tert-butanol in the treated waste gas is condensed and absorbed, and is discharged to the corresponding water treatment unit along with the waste water. Exhaust gas passes through N 2 Diluted, N 2 The volume concentration of O is reduced to 60100ppm, and the concentration of tert-butanol in the exhaust gas after pretreatment is 2010mg / m 3 ;

[0068] (2) Catalytic reaction: The pretreated exhaust gas enters the 2-stage adiabatic fixed-bed catalytic reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com