Method for preparing CeO2/TiO2 low-temperature SCR catalyst by using Ce-MOF as cerium precursor

A technology of SCR catalyst and precursor, which is applied in the field of catalyst preparation, can solve the problems of limited application of MOF-based materials, achieve the effects of improved dispersion, simple process, and easy-to-obtain experimental raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

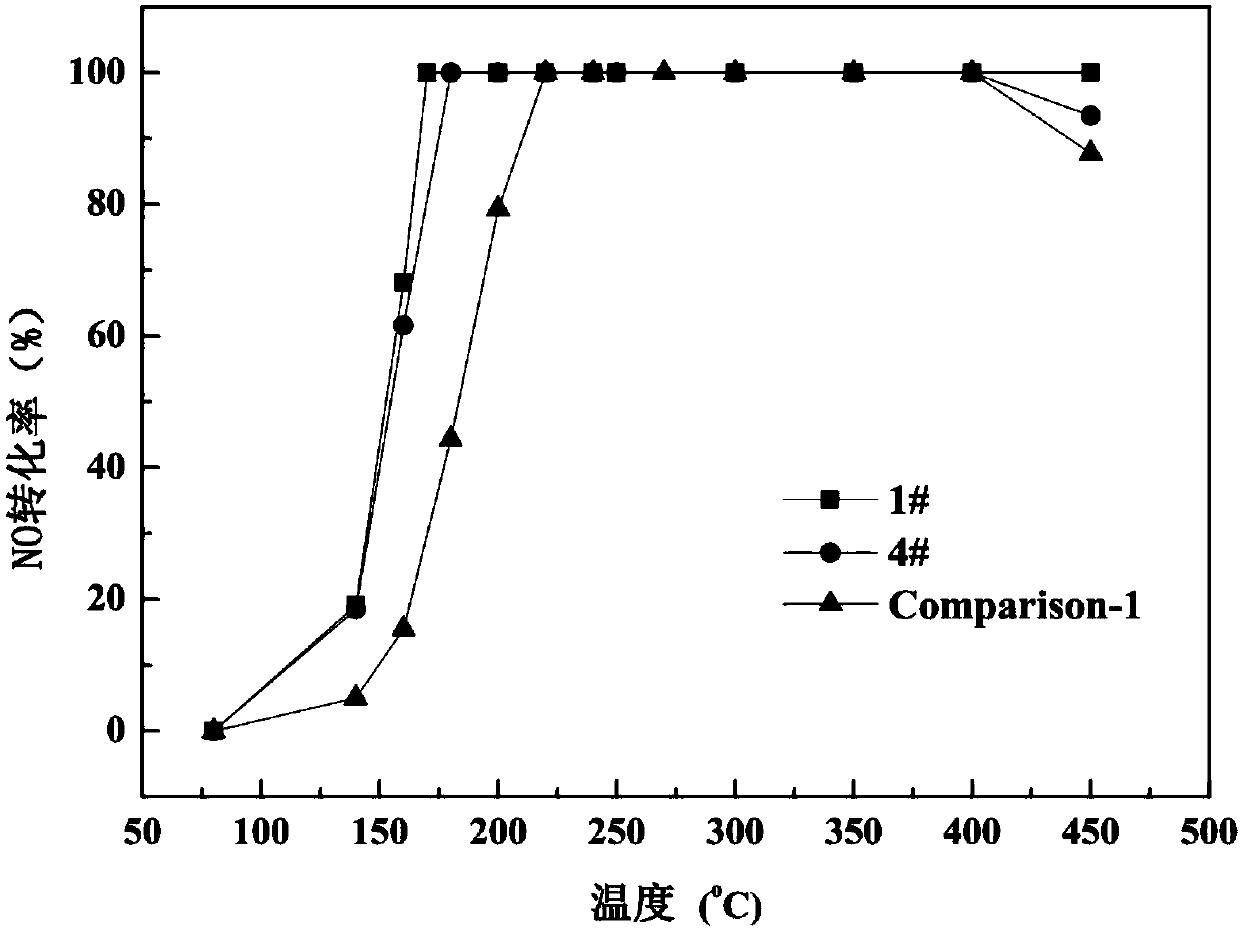

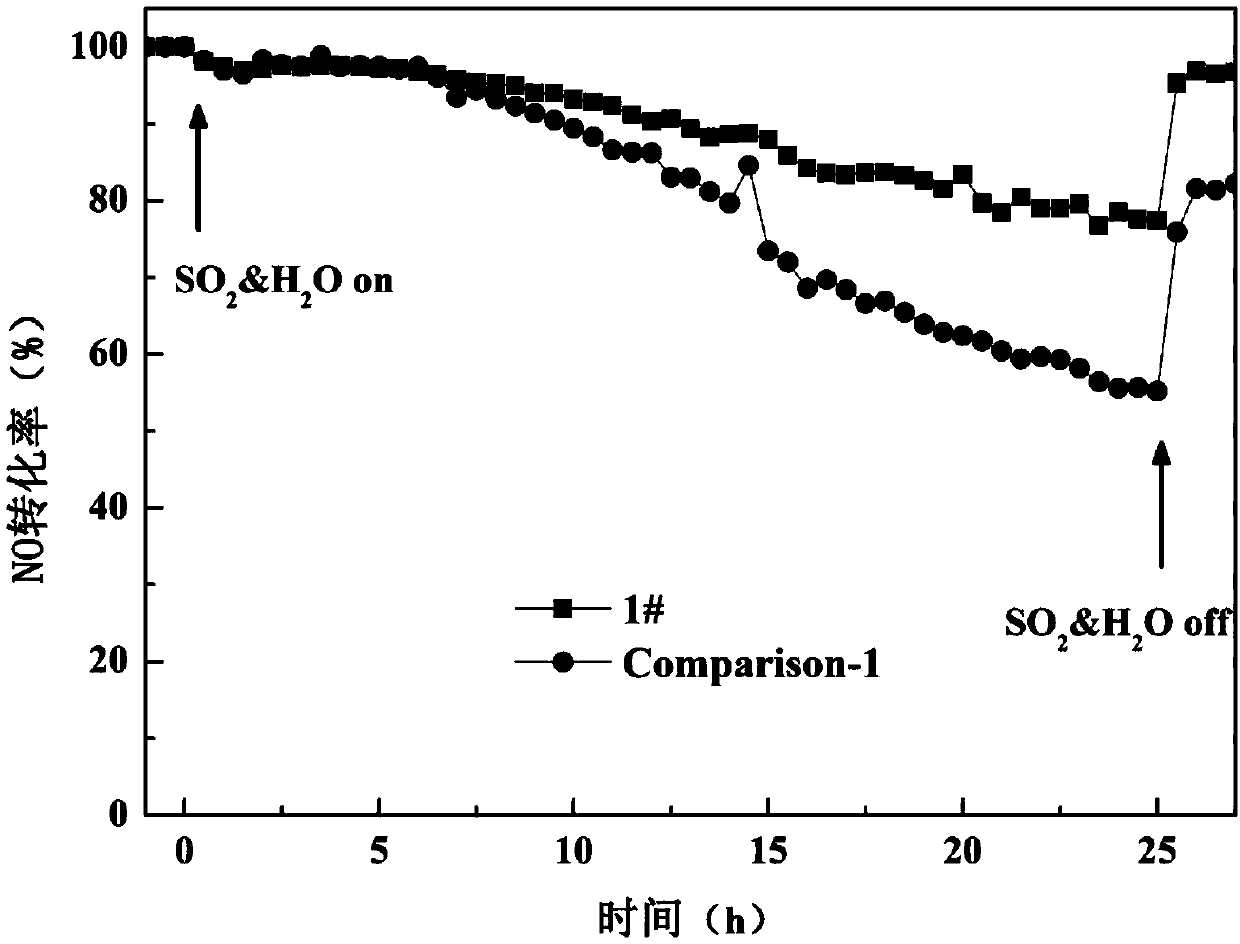

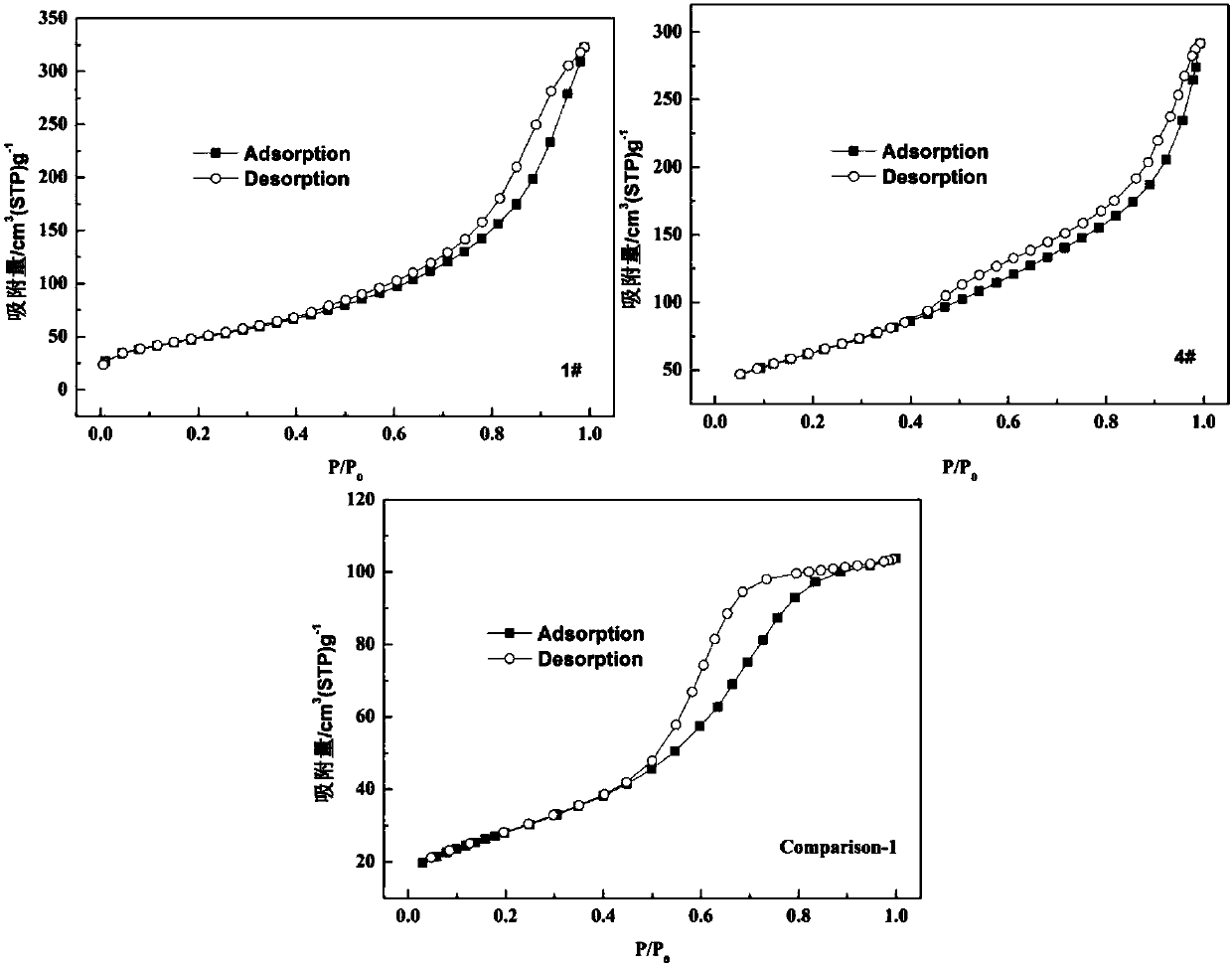

Embodiment 1

[0026]Weigh 29.4g of titanyl sulfate, dissolve it in 300ml of deionized water, stir for 4h, add the prepared Ce-MOF-112.4g, stir for 2h, slowly add ammonia water with a concentration of 25% to adjust the pH of the system to 10, continue stirring for 6h , stop stirring and let stand for 12h. Filter and dry the solid at 80°C for 12h, then put the dried powder into a muffle furnace and calcinate at 450°C for 2h in an air atmosphere to obtain 1# catalyst sample.

Embodiment 2

[0028] Weigh 29.4g of titanyl sulfate, dissolve it in 300ml of deionized water, stir for 4h, add the prepared Ce-MOF-112.4g, stir for 2h, slowly add ammonia water with a concentration of 25% to adjust the pH of the system to 11, continue stirring for 6h , stop stirring and let stand for 12h. Filter and dry the solid at 80°C for 12h, then put the dried powder into a muffle furnace and calcinate at 450°C for 2h in an air atmosphere to obtain 2# catalyst sample.

Embodiment 3

[0030] Weigh 29.4g of titanyl sulfate, dissolve it in 300ml of deionized water, stir for 4h, add the prepared Ce-MOF-112.4g, stir for 2h, slowly add ammonia water with a concentration of 25% to adjust the pH of the system to 10, continue stirring for 6h , stop stirring and let stand for 12h. Filter, dry the solid at 80°C for 12h, then put the dried powder into a muffle furnace, and calcinate at 550°C for 2h in an air atmosphere to obtain 3# catalyst sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com