High-efficiency catalyst for purifying tail gas of adipic acid device, and forming technology method of catalyst

A molding process, adipic acid technology, applied in physical/chemical process catalysts, adipic acid production, nitrous oxide capture, etc., can solve the limitations of the development of adipic acid device tail gas purification technology, the catalyst cannot be directly formed and batched Production, difficult to meet the requirements of industrial shaped catalysts, etc., to achieve the effects of saving preparation time and cost, good economic applicability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

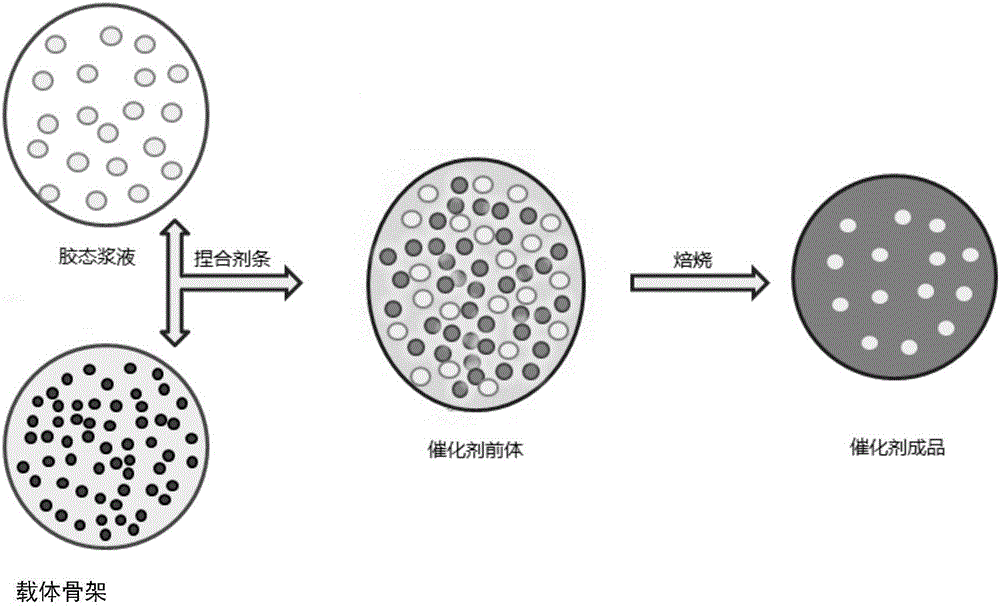

Method used

Image

Examples

Embodiment 1

[0035] Directly shaped Rh-CoFe 2 o 4 / Al 2 o 3 catalyst:

[0036] (1) Co(NO 3 ) 2 , FeSO 4 , Fe 2 (SO 4 ) 3 and Rh(NO 3 ) 3 Dissolve in deionized water according to 1:2:0.5:0.05 (molar ratio) to obtain a metal salt solution with a total concentration of metal ions of 0.85M; the molar ratio is [OH - Total charge]: [metal ion charge total]=2.0 prepare lye, dissolve completely until the solution is transparent. The metal salt solution and the lye sub-channel are injected into the cyclone reactor at the same time, and after rapid reaction, the obtained colloidal slurry is transferred to the reaction kettle, and crystallized at 90° C. for 3 hours.

[0037] (2) Take a certain amount of colloidal slurry, add pseudo-boehmite, safflower powder and peptizer to the precursor slurry, and control the water-powder ratio of the total material to 0.65L Kg -1 , the mass ratio of safflower powder and pseudo-boehmite is 5%, stir evenly, age at room temperature for 2h, then knead, ex...

Embodiment 2

[0041] Directly formed CuO+ZnAl 2 o 4 / SiO 2 catalyst:

[0042] (1) Adding Cu(NO 3 ) 2 , Zn(NO 3 ) 2 with Al(NO 3 ) 3 Dissolve in deionized water at 1:1:1 (molar ratio) to obtain a metal salt solution with a total concentration of metal ions of 0.4M; press [NaOH]:[hexamethylenetetramine]:[NO 3 - ]=1:2:1 prepare lye, dissolve completely until the solution is transparent. The metal salt solution and the lye sub-channel are injected into a high-speed rotating cyclone reactor at the same time, and after rapid mixing, the obtained colloidal slurry is transferred to a reaction kettle and crystallized at 60° C. for 5 hours.

[0043] (2) Take a certain amount of colloidal slurry, add silica sol and squash powder to the precursor slurry, and control the water-powder ratio of the total material to 0.80L Kg -1 , the mass ratio of safflower powder and silica sol is 3%, stir evenly, age at room temperature for 3h, then knead, use extruder to extrude into a clover shape with a di...

Embodiment 3

[0047] Directly shaped CeO 2 +NiFe 2 o 4 / Al 2 o 3 catalyst:

[0048] (1) Ce(NO 3 ) 2 , Ni(NO 3 ) 2 with Fe(NO 3 ) 3 Dissolve in deionized water at 0.1:2:0.5 (molar ratio) to obtain a metal salt solution with a total concentration of 0.5M; press [NaOH]:[ammonia]:[NO 3 - ]=2:2:1 prepare lye, dissolve completely until the solution is transparent. The metal salt solution and the lye sub-channel are injected into a high-speed rotating cyclone reactor at the same time, and after rapid mixing, the obtained colloidal slurry is transferred to a reaction kettle, and crystallized at 120° C. for 3 hours.

[0049] (2) Take a certain amount of colloidal slurry, add sulfonated polystyrene and aluminum sol with a diameter of 1 μm to the precursor slurry, and control the water-powder ratio of the total material to 0.95L Kg -1 , the mass ratio of sulfonated polystyrene and aluminum sol is 0.5wt%, stir evenly, age at room temperature for 1h, then knead, extrude into a five-leaf clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com