System and method for utilizing heat energy of oximation device

A technology of thermal energy and oximation, which is applied in chemical instruments and methods, oxime preparation, chemical industry, etc., can solve the problems that heat cannot be utilized step by step, heat wastes production costs, and multi-circulation cooling water, etc., to achieve maximum application, The effect of guaranteeing heat demand and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

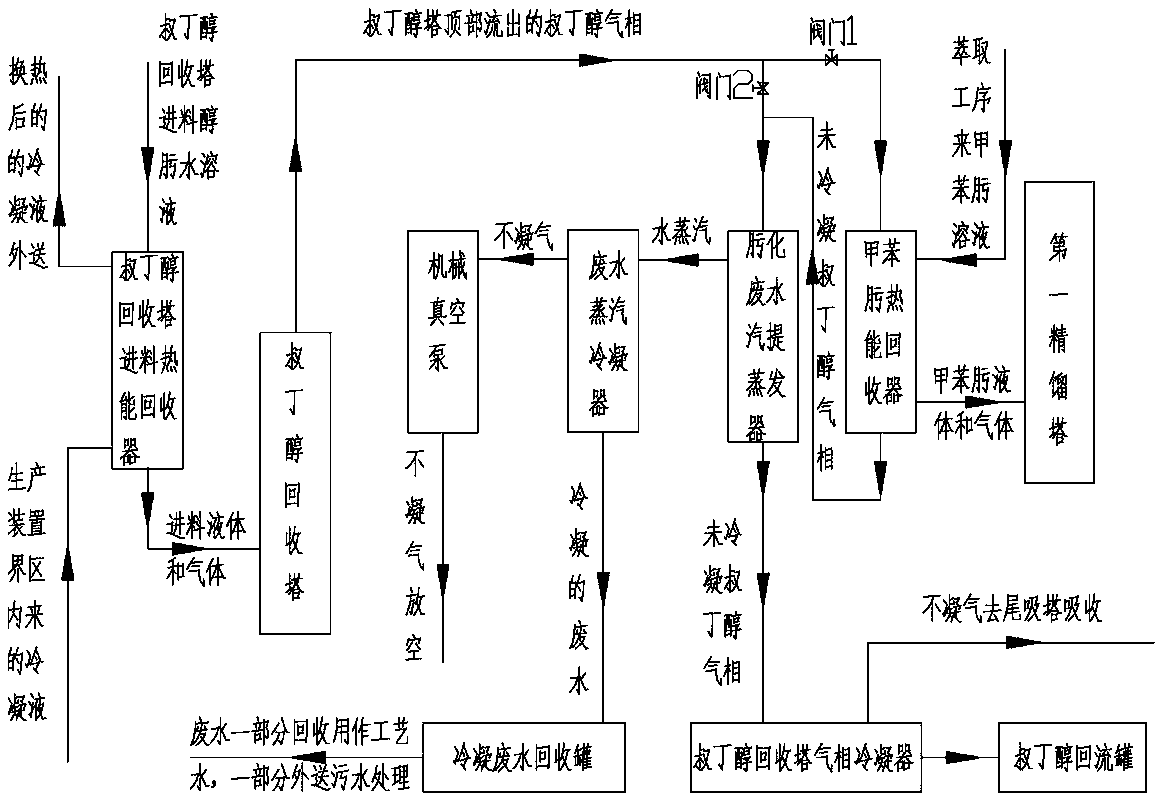

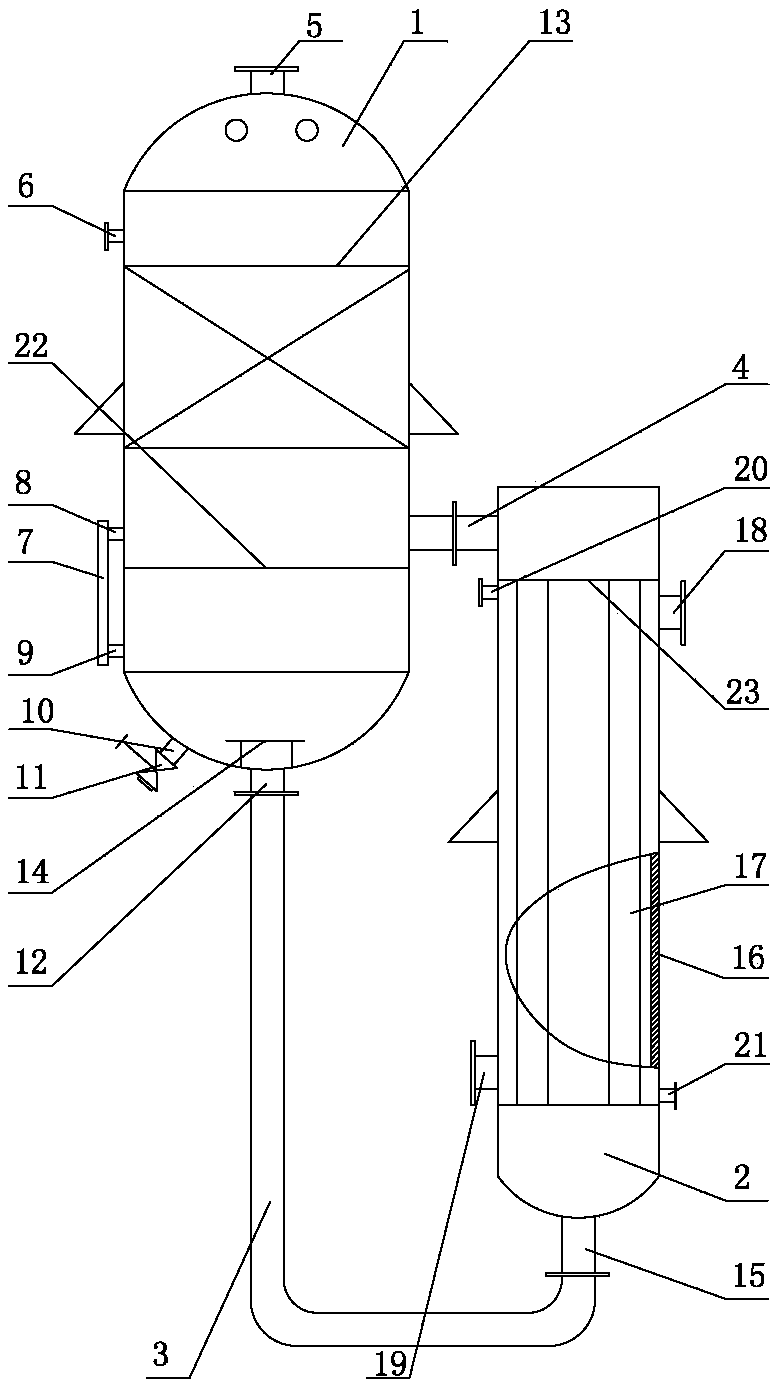

[0045] like figure 1 As shown in the figure, a thermal energy utilization system of an oximation device includes a tert-butanol recovery tower feed thermal energy recovery device, a tert-butanol recovery column, a valve 1, a valve 2, an oximation wastewater stripping evaporator, a toluoxime thermal energy recovery device, The first rectification column, the tert-butanol recovery column gas phase condenser, the tert-butanol reflux tank, the waste water vapor condenser, the mechanical vacuum pump and the condensation waste water recovery tank, and the oximation waste water stripping evaporator and the toluoxime heat energy recovery device are combined, arranged in series;

[0046] The material inlet of the tert-butanol recovery tower feed heat energy recovery device is connected with the alcohol oxime solution feed pipeline, the material gas-liquid outlet of the tert-butanol recovery tower feed heat energy recovery device is connected with the material inlet of the tert-butanol ...

Embodiment 2

[0048] A method for utilizing heat energy of an oximation device, such as figure 1 shown, including the following steps:

[0049] ①The tert-butanol gas-phase steam at 78-90°C flowing out of the gas-phase outlet of the tert-butanol recovery tower is divided into two paths. The oxime is heated, and the heated toloxime gas-liquid enters the first rectifying tower, and the temperature of the toloxime before and after heating is respectively 45~50 ℃ and 60~75 ℃, and the temperature of the tert-butanol gas phase after cooling is 65~85 ℃, Then mix with the second tert-butanol gas phase behind valve 2;

[0050] ②The second tert-butanol gas phase steam is mixed with the uncondensed tert-butanol gas phase after exiting the toluoxime heat energy recovery device and enters the oximation wastewater stripping evaporator to evaporate and strip the toluene in the oximation wastewater, and the tert-butanol gas phase The temperature is cooled to 60~80 ℃, the cooled tert-butanol gas phase ente...

Embodiment 3

[0054] The system equipment is the same as the embodiment 1, and the production method is the same as the embodiment 2, and the difference is:

[0055] The temperature of the gas phase outlet of the tert-butanol recovery tower is 78°C, the temperature of the toloxime increases from 45°C to 60°C after passing through the toluoxime heat energy recovery device, and the temperature of the gas phase of the tert-butanol after cooling is 65°C; The temperature of the tert-butanol gas phase in the evaporator was 60°C.

[0056] Step 4. is that the temperature of the steam condensate with a temperature of 110°C from the caprolactam production unit area is 90°C after heat exchange, and the temperature of the tert-butanoloxime aqueous solution is raised from 75°C to 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com