Preparation method and application of Fe-ZSM-5 doped Rh and Er composite catalyst

A fe-zsm-5, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

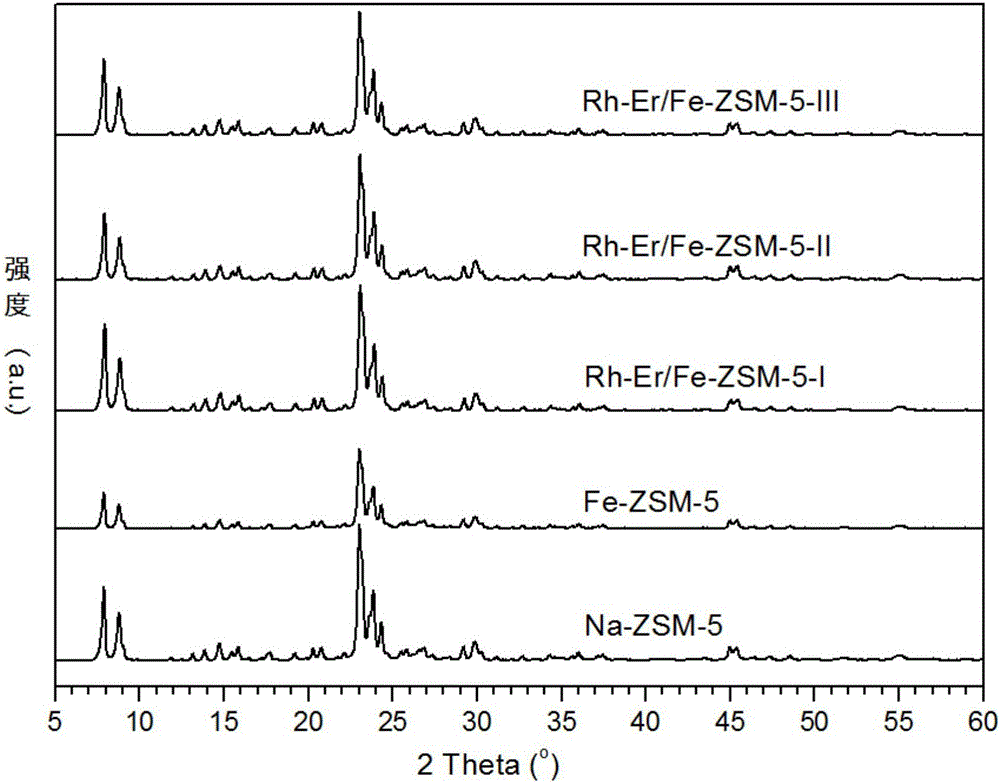

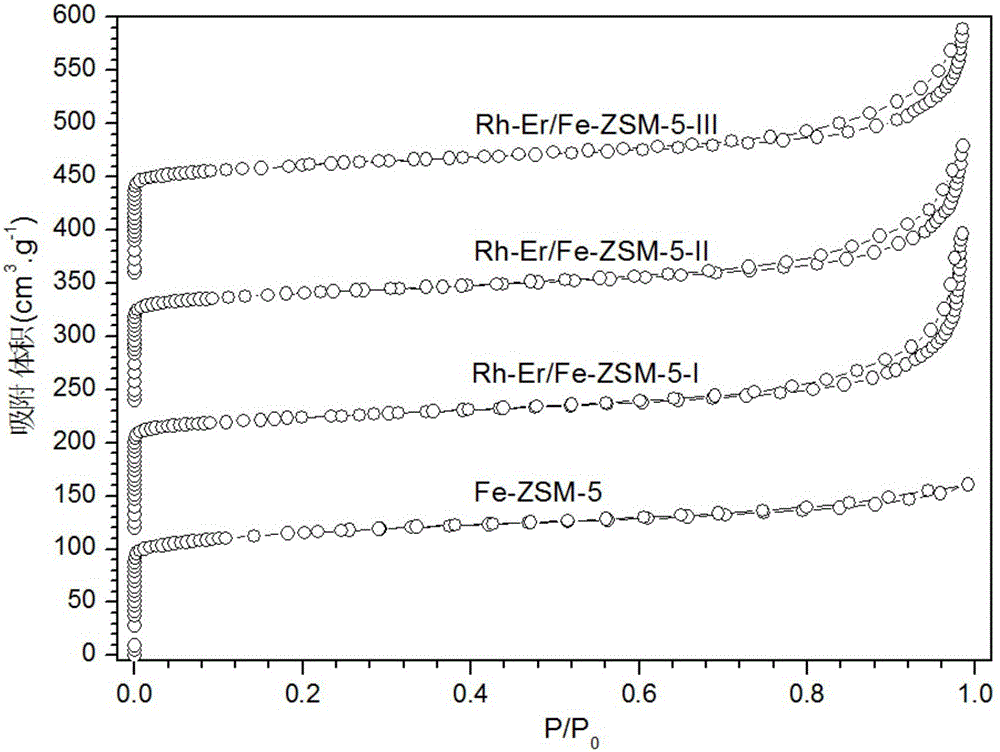

[0021] (1) Na-ZSM-5 molecular sieve with a silicon-aluminum ratio of 20mol:1mol and 0.3mol.L -1 The solution was ion exchanged at 60°C for 2h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g: 1.5mol. The above process is repeated twice, filtered, washed 4 times, and dried at 130°C for 20h to obtain NH 4 -ZSM-5 molecular sieve; Gained NH 4 -ZSM-5 molecular sieve added to 0.01mol.L -1 Fe(NO 3 ) 3 Medium, ion exchange at 70°C for 3h, where NH 4 -ZSM-5 molecular sieve and Fe(NO 3 ) 3 The ratio is 100g:0.05mol. The ion exchange of the precursor is repeated twice, filtered, washed four times, dried at 130°C for 20h, and calcined at 450°C for 4h to obtain Fe-ZSM-5.

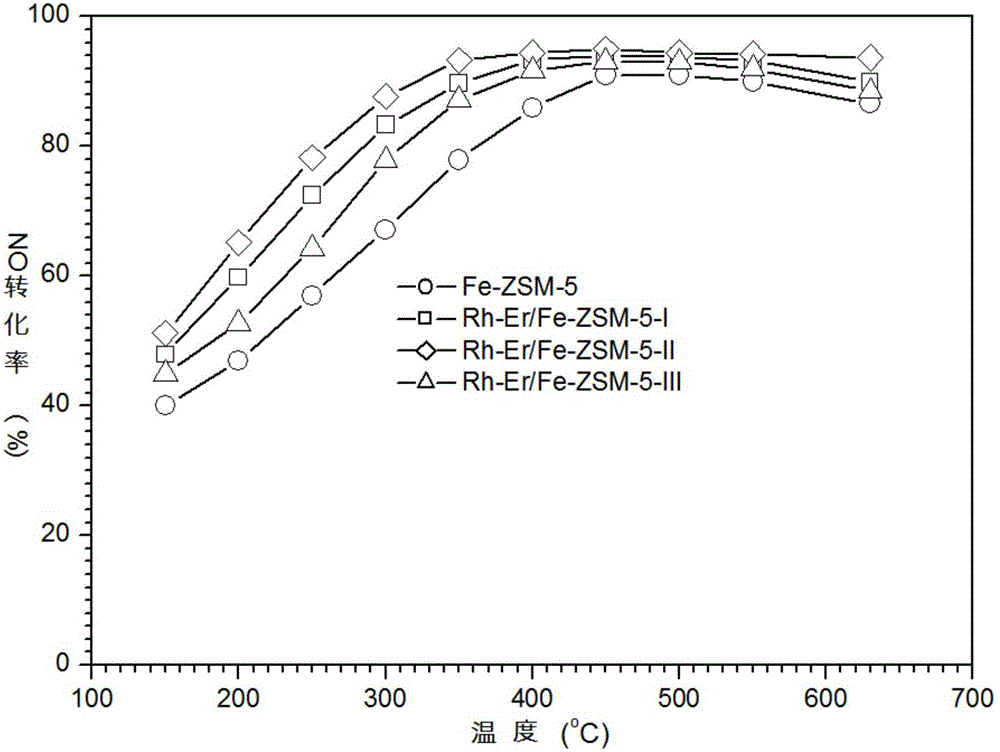

[0022] (2) Catalyst of the present invention, at 120,000mL.(g.h) -1 At air speed, 300ppm NH 3 , 10vl.%O 2 Concentration and 5wt% H 2 Under the condition of O concentration, in a wide temperature range (150 ° C ~ 550 ° C), it has high catalytic activity to eliminate low concentration NO (500 ...

Embodiment 2

[0024] (1) Na-ZSM-5 molecular sieve with a silicon-aluminum ratio of 20mol:1mol and 0.1mol.L -1 NH 4 Cl solution was ion-exchanged at 60°C for 2h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g:0.6mol, the above process is repeated once, filtered, washed three times, and dried at 120°C for 18h to obtain NH 4 -ZSM-5 molecular sieve; Gained NH 4 -ZSM-5 molecular sieve added to 0.01mol.L -1 Fe(NO 3 ) 3 Medium, ion exchange at 60°C for 2h, where NH 4 -ZSM-5 molecular sieve and Fe(NO 3 ) 3 The ratio is 100g:0.02mol, and the ion exchange of the precursor is repeated once, filtered, washed three times, and dried at 120°C for 18 hours to obtain the Fe-ZSM-5 precursor. Then mix 0.0001mol.L evenly -1 Rh(NO 3 ) 3 solution and 0.0001mol.L -1 Er(NO 3 ) 3 solution, in which Rh(NO 3 ) 3 with Er(NO 3 ) 3 The molar ratio is 1:1, the Fe-ZSM-5 precursor prepared above is added to the above mixed solution, and impregnated for 24 hours by impregnation method, ...

Embodiment 3

[0027] (1) Na-ZSM-5 molecular sieve with a silicon-aluminum ratio of 23mol:1mol and 0.3mol.L -1 NH 4 Cl solution was ion-exchanged at 70°C for 3h, in which Na-ZSM-5 molecular sieve and NH 4 The ratio of Cl is 100g:2.0mol, the above process is repeated twice, filtered, washed four times, and dried at 130°C for 20h to obtain NH 4 -ZSM-5 molecular sieve; Gained NH 4 -ZSM-5 molecular sieve added to 0.015mol.L -1 Fe(NO 3 ) 3 In, ion exchange at 780°C for 3h, where NH 4 -The ratio of ZSM-5 molecular sieve to Fe(NO3)3 is 100g:0.035mol. The ion exchange of the precursor is repeated twice, filtered, washed 4 times, and dried at 130°C for 20h to obtain the Fe-ZSM-5 precursor. Then mix 0.0002mol.L evenly -1 Rh(NO 3 ) 3 solution and 0.0002mol.L -1 Er(NO 3 ) 3 solution, in which Rh(NO 3 ) 3 with Er(NO 3 ) 3 The molar ratio is 1:1, the Fe-ZSM-5 precursor prepared above is added to the above mixed solution, and impregnated for 36 hours by impregnation method, wherein, the Fe-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com